Polyolefin composition and preparation method thereof, and polyolefin material

A technology of polyolefin and composition, which is applied in the field of polyolefin materials, can solve the problems of low molding shrinkage, difficult to take into account at the same time, high haze, etc., and achieve the effect of low molding shrinkage and haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] According to a preferred embodiment, the MFR of the propylene / 1-butene copolymer measured under the conditions of 230° C. and 2.16 kg is 20-30 g / 10 min.

[0029] In the present invention, as the dispersed phase in the polyolefin composition, the ethylene / 1-butene copolymer is an elastic copolymer, and the elastic copolymer has a good phase relationship with the ethylene / 1-butene copolymer. Compatibility, so as to ensure that the material prepared from the polyolefin composition can meet relatively high comprehensive mechanical properties, and at the same time have good optical properties and processability.

[0030] Preferably, the MFR of the polyolefin composition measured under the conditions of 230° C. and 2.16 kg is 10-20 g / 10 min.

[0031] In the polyolefin composition, the intrinsic viscosity of the part soluble in xylene at room temperature is usually 0.8-1.5 dL / g, preferably 0.9-1.3 dL / g.

[0032] According to the present invention, the content of the polyolefi...

Embodiment 1

[0090] This example is used to illustrate the polyolefin composition and its preparation method and polyolefin material of the present invention.

[0091] The titanium-containing active solid catalyst component (main catalyst) is prepared by the method described in Example 1 of CN93102795.0, its Ti content: 2.2% by weight, di-n-butyl phthalate (DIBP) content: 11.2% by weight.

[0092] The polymerization reaction was carried out on a polypropylene pilot plant.

[0093] Polymerization method and steps are as follows:

[0094] Pre-polymerization: After the main catalyst, co-catalyst (triethylaluminum (TEA)), external electron donor compound (methylcyclohexyldimethoxysilane (CHMMS)) was pre-contacted at 10°C for 20 minutes, the pre-polymerization was continuously added The reactor was subjected to a prepolymerization reaction, wherein the flow rate of TEA was 6 g / hr, the flow rate of CHMMS was 1.02 g / hr, and the flow rate of the main catalyst was 0.36 g / hr. The pre-polymerizatio...

Embodiment 2

[0101] This example is used to illustrate the polyolefin composition and its preparation method and polyolefin material of the present invention.

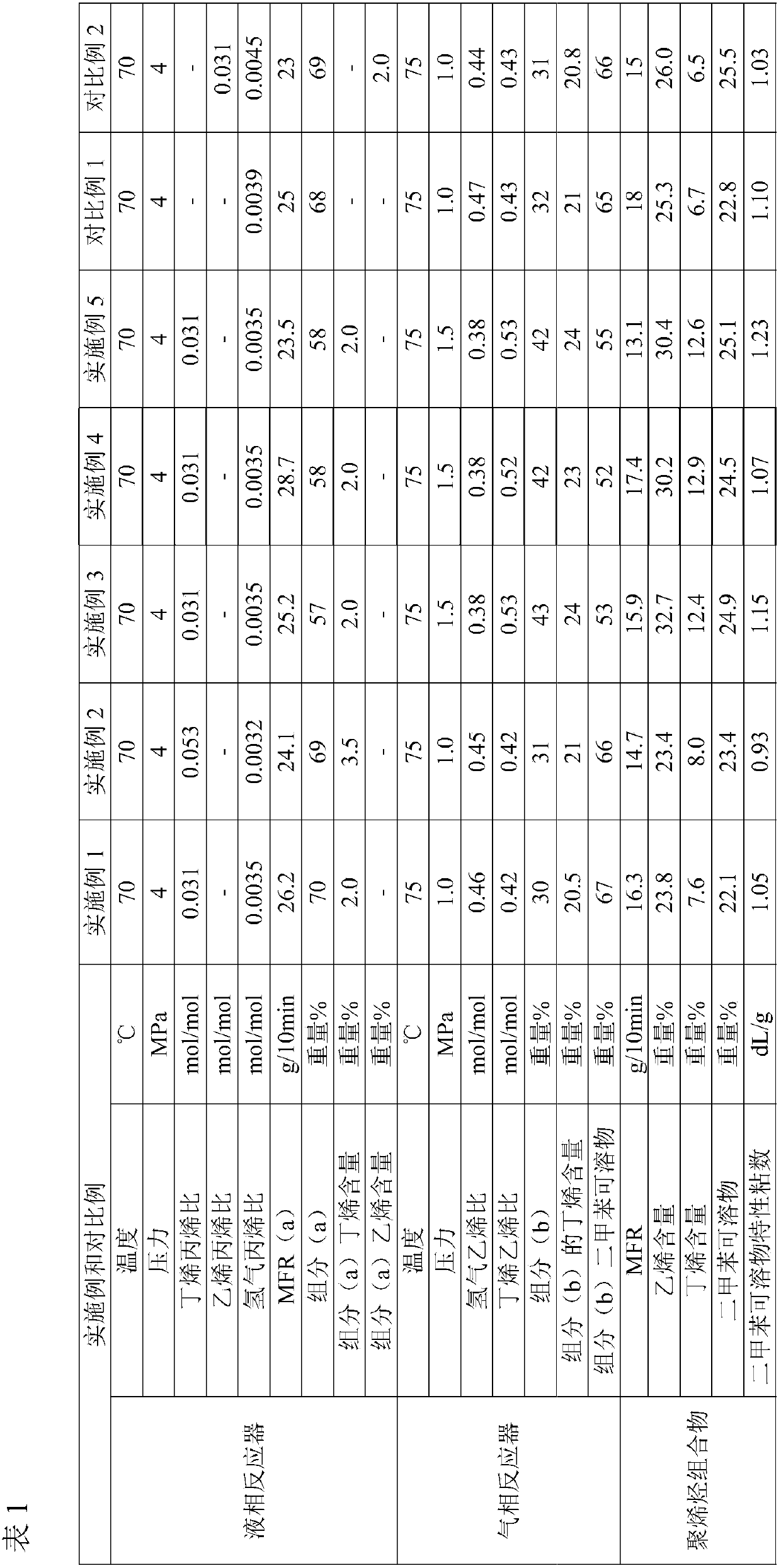

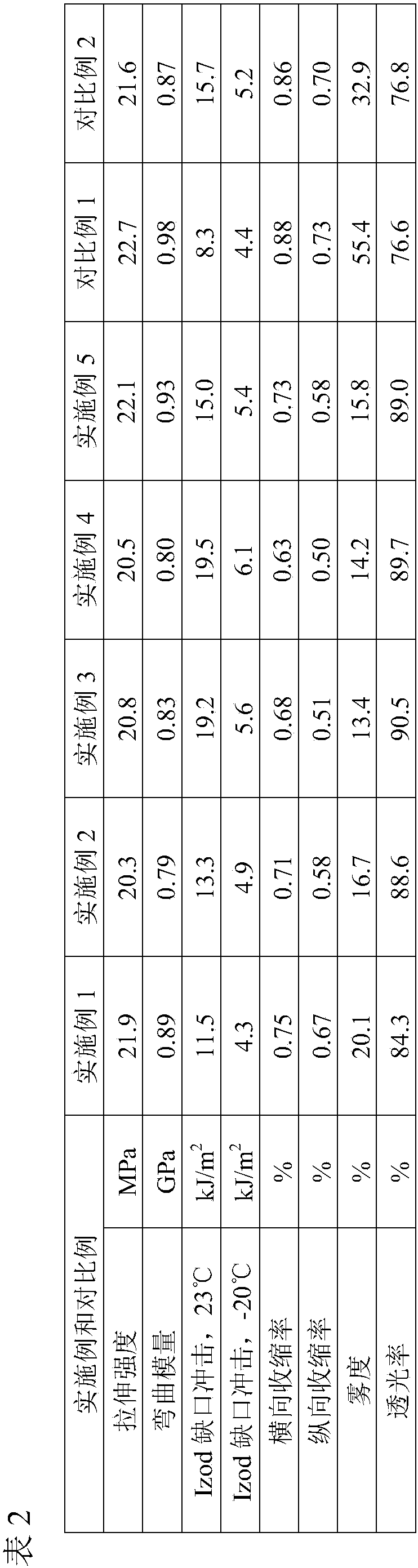

[0102] The polyolefin composition and polyolefin material were prepared according to the method of Example 1, except that the amount of reactants was adjusted so that the concentration of butene detected by online chromatography in the loop reactor was 5 mol%, and the concentration of hydrogen was 0.32 mol%. The specific process conditions and the composition of the polyolefin composition are shown in Table 1, and the properties of the polyolefin material are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com