Linen and cotton mesh fabric which prevents itch

A mesh fabric, itching technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of high cost, high energy consumption, complicated process, etc., and achieve easy production, simple preparation process, good moisture absorption and sweat conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

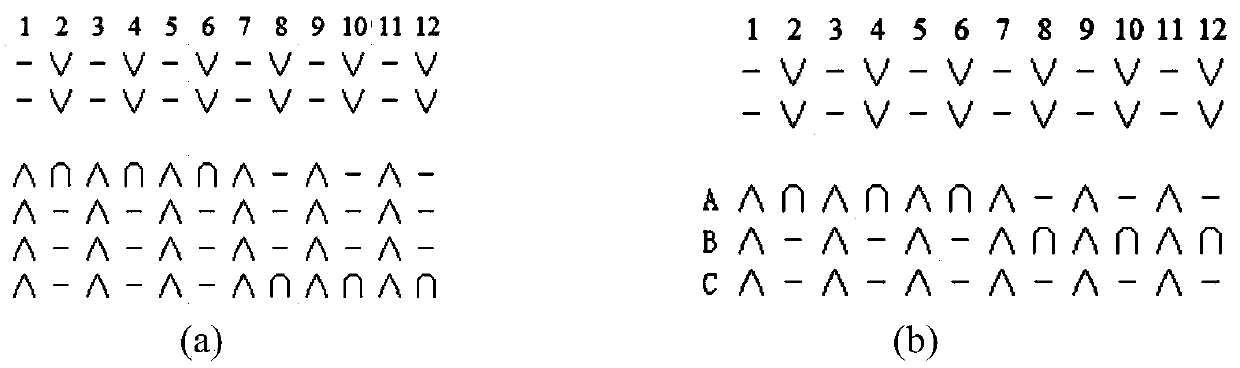

[0036] A hemp brocade mesh fabric without itching, the fabric has a double-sided tuck mesh structure, the outer layer is pure hemp yarn, and the inner layer is nylon yarn. The outer layer is a mesh structure with vertical stripes. The pure hemp yarn is spun from hemp fibers with a yarn count of about 1.45 dtex, and the nylon yarn is spun from 40D / 24f cross-section nylon staple fibers, and the length of the nylon staple fibers is 38mm. Use 34" 28G60F double-sided computerized jacquard circular machine for weaving, single-pass nylon yarn, needles in a row, specific as figure 1 (a) The organization chart shown.

Embodiment 2

[0038] A hemp brocade mesh fabric without itching, the fabric has a double-sided tuck mesh structure, the outer layer is pure hemp yarn, and the inner layer is nylon yarn. The outer layer is a mesh structure with vertical stripes. The pure hemp yarn is spun from hemp fibers with a yarn count of about 1.45 dtex, and the nylon yarn is spun from 40D / 24f cross-section nylon staple fibers, and the length of the nylon staple fibers is 38mm. Use 34"28G60F double-sided computerized jacquard circular machine for weaving, use single-pass nylon yarn, needle row: A B A C C C, specific as figure 1 (b) The organization chart shown.

Embodiment 3

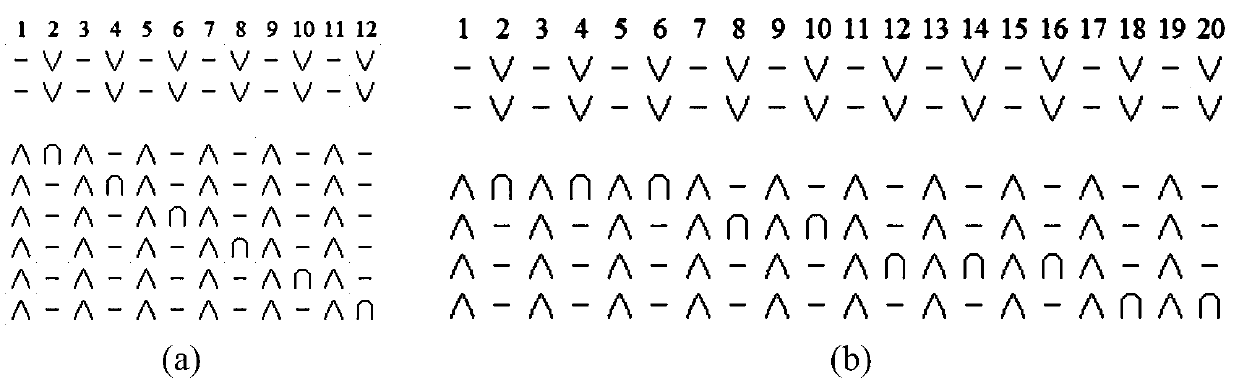

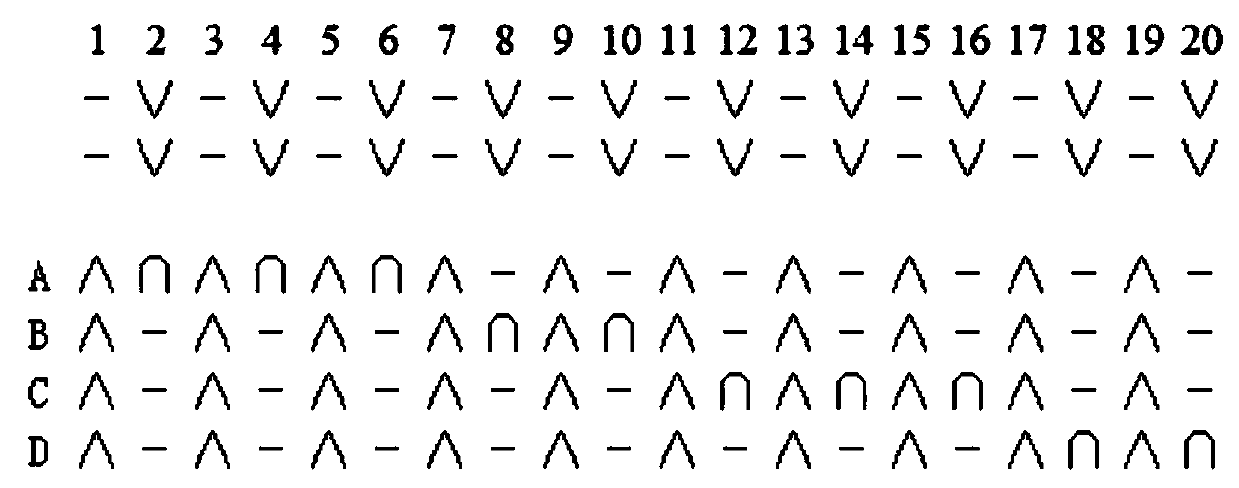

[0040] A hemp brocade mesh fabric without itching, the fabric has a double-sided tuck mesh structure, the outer layer is pure hemp yarn, and the inner layer is nylon yarn. The outer layer is a twill mesh construction. The pure hemp yarn is spun from hemp fibers with a yarn count of about 1.45 dtex, and the nylon yarn is spun from 40D / 24f cross-section nylon staple fibers, and the length of the nylon staple fibers is 38mm. Use 34" 28G60F double-sided computerized jacquard circular machine for weaving, single-pass nylon yarn, needles in a row, specific as figure 2 Organization diagrams shown in (a) and (b).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com