Whole-process traceable semiconductor test data recording method

A technology for testing data and recording methods, applied in the field of testing, which can solve problems such as data cannot be traced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

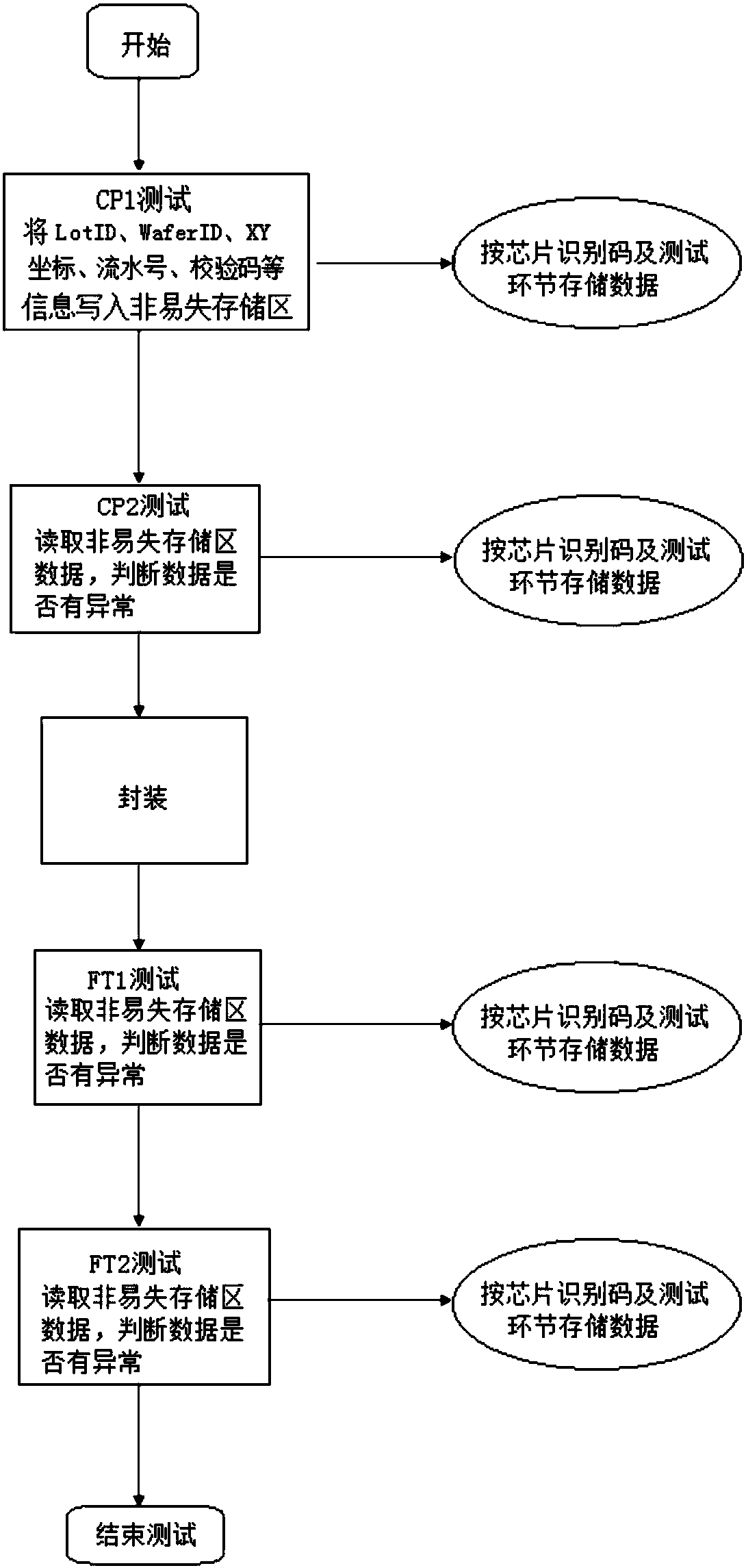

[0012] Wafer test CP: use test equipment to test the chip to be tested on the wafer; finished product test FT: use test equipment to test the packaged semiconductor chip; aging: the method of accelerating the damage of semiconductor chip by high temperature baking; test Detailed data, including the coordinates of the tested device on the original wafer, the name of the test item, the test value, the test condition, the judgment condition, etc.

[0013] In the process of the first test of the wafer, the present invention writes the unique identification code of the chip in the non-volatile storage area of the tested chip, including but not limited to LotID (batch number), WaferID (wafer number), the Measure the XY coordinates, serial number, check code, etc. of the chip on the original wafer. At the same time, use this identification code plus the test link identification (such as the first test of the wafer, etc.) as the index information of the data file of the chip under te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com