Method for producing a plastic frame for a two-wheeled vehicle

A two-wheeled, plastic technology, used in bicycle racks, bicycle accessories, other household appliances, etc., can solve the problems of non-recycling, no reasonable recycling method for parts, etc., to shorten the total time, shorten the cooling time, and quickly cool down. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

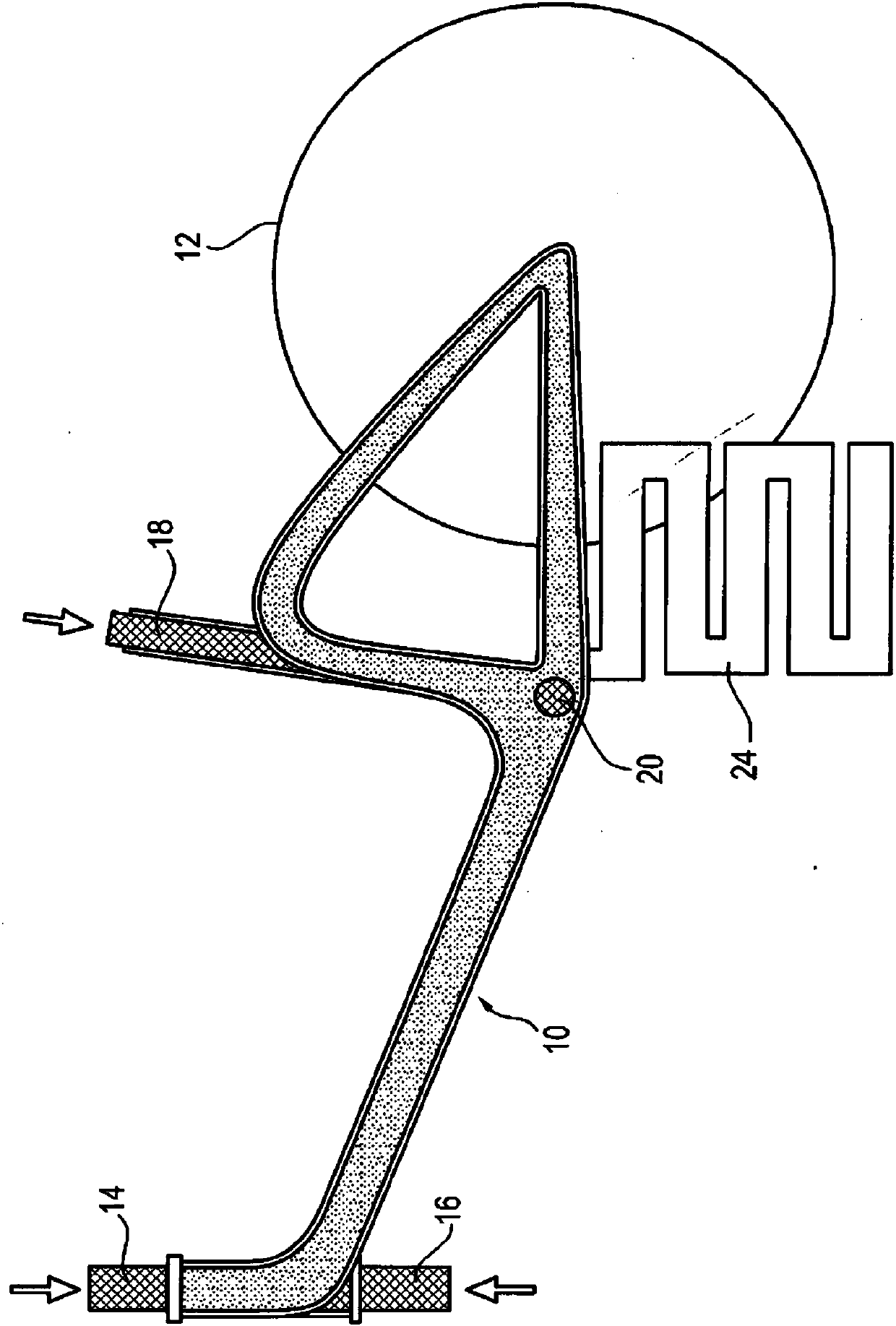

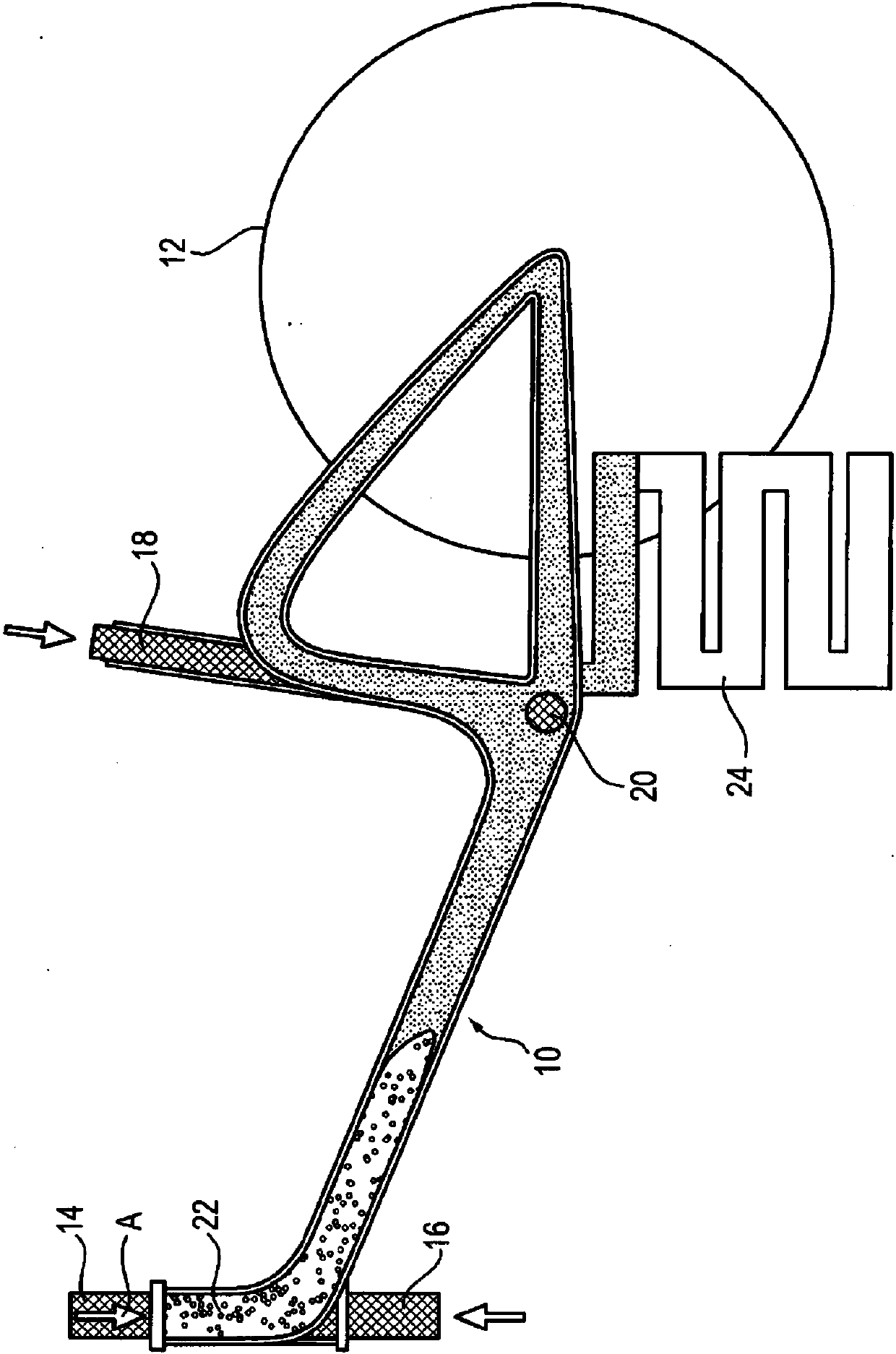

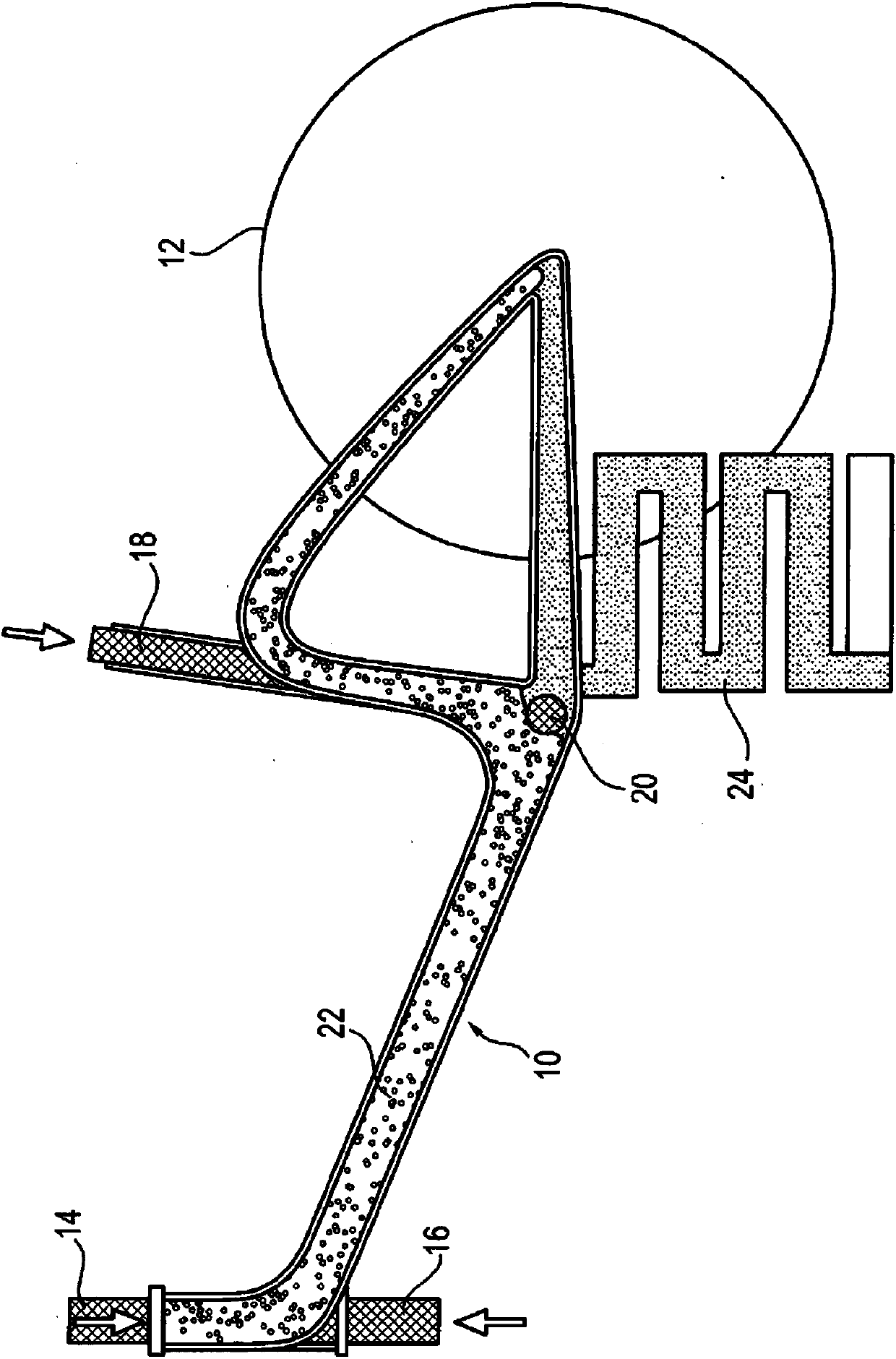

[0035] According to the general method route of the method for manufacturing the plastic frame of a two-wheeled vehicle according to the present invention, reference can be made to the Figure 1 to Figure 5 The first embodiment of the present invention will be explained.

[0036] therefore figure 1 A frame 10 of a women's bicycle is schematically shown in . Rear wheels 12 arranged at the rear of the frame are shown schematically. figure 1 It is shown, but not in detail, that the thermoplastic melt has just been injected into the closed forming tool. Simultaneously, slides or cores 14, 16 and 18 have been pushed into the forming tool in the direction of the respective arrows in order to prevent injected plastic melt from penetrating into this area. Sliders 14 and 16 here form a cavity for turning the head bearing; slider 18 forms a cavity for receiving a seat tube to be installed later; and slider 20 inserted perpendicular to the plane of the figure forms a later The hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com