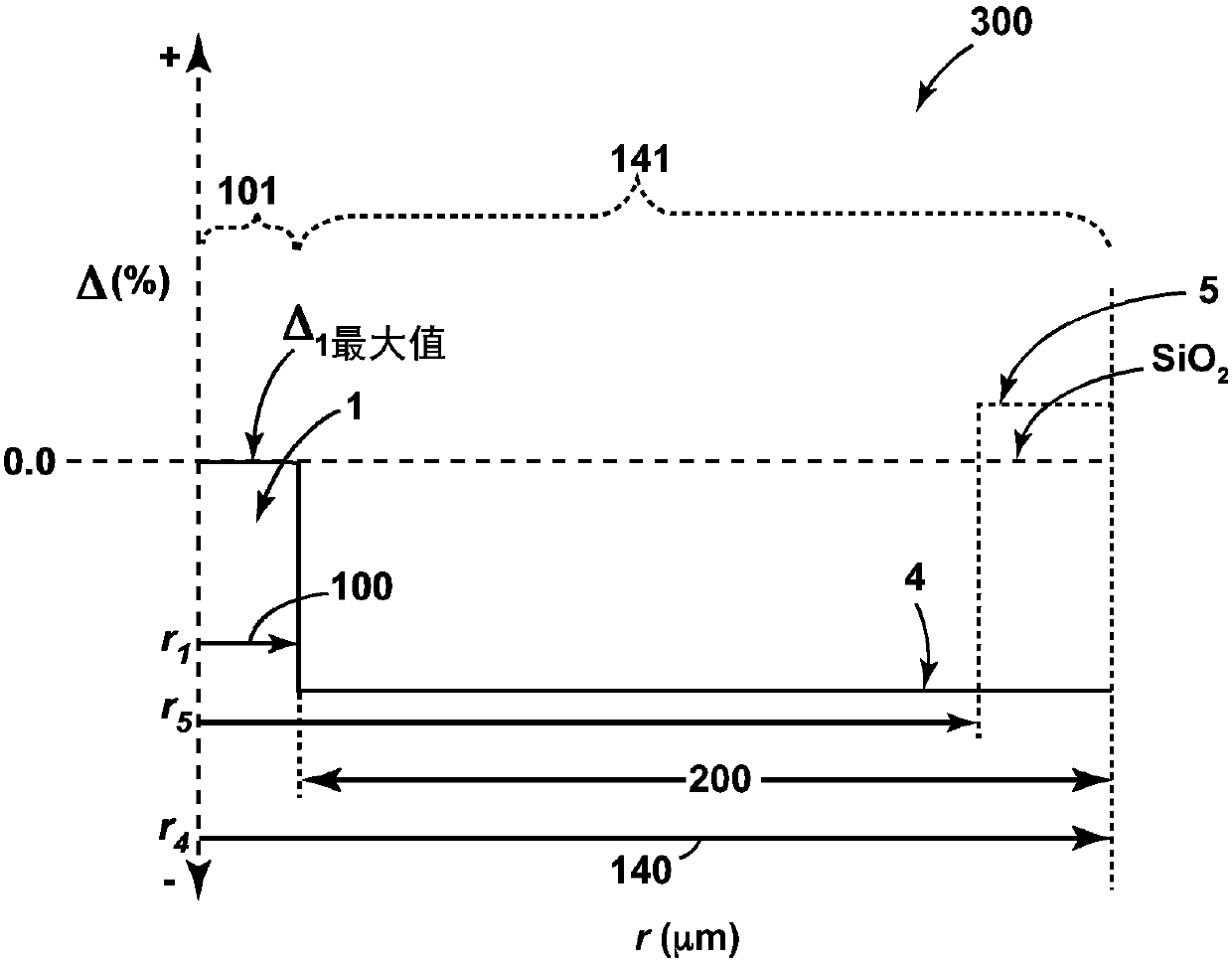

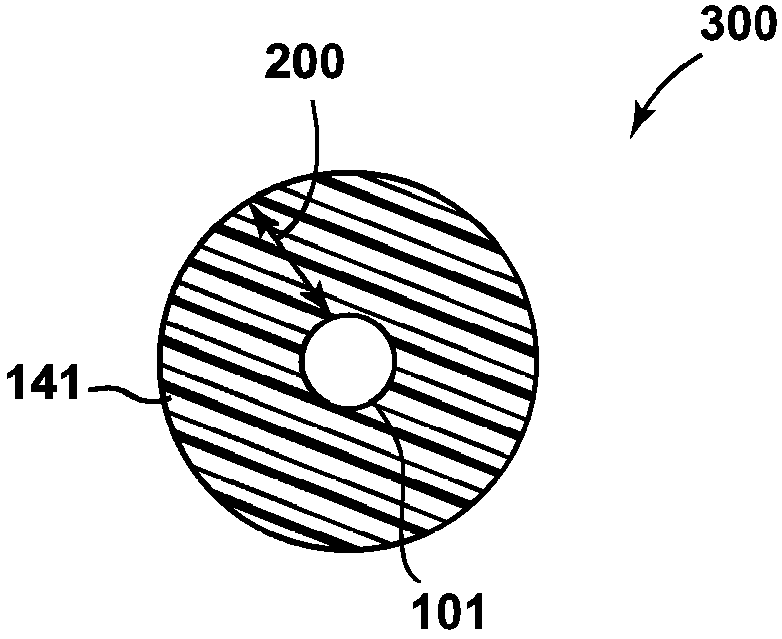

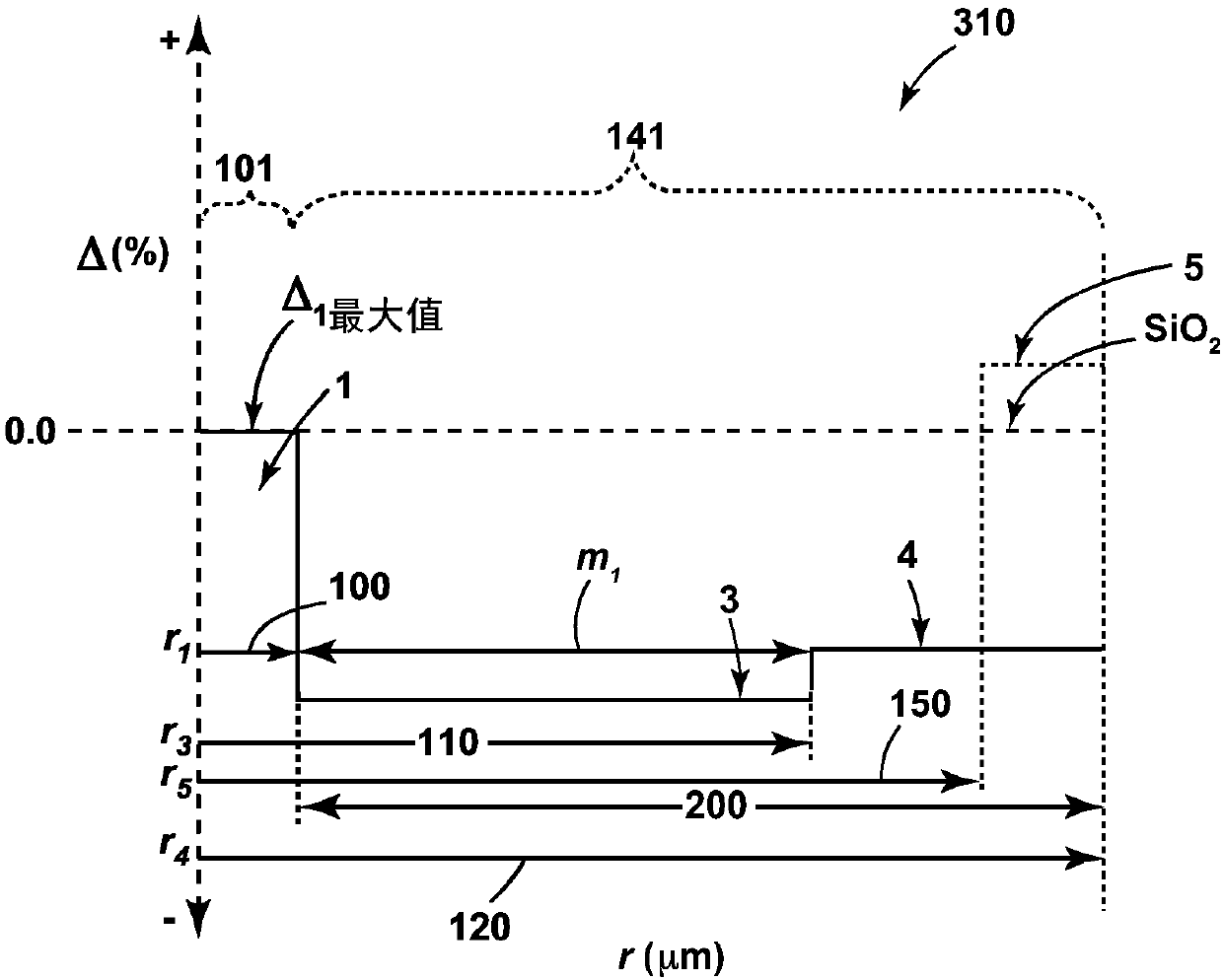

Low loss optical fibers with fluorine and chlorine codoped core regions

A co-doping, optical fiber technology, applied in the direction of multi-layer core/cladding fiber, graded index core/cladding fiber, cladding fiber, etc., can solve fiber attenuation, low intermodal dispersion level, loss And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] In a lathe, prepare a density of approximately 0.5 g / cm by 3 1 meter long 3000 gram silica soot preform: Silica soot was flame deposited onto a 10 mm diameter removable alumina spinner rod, which contained a silica handle. The soot preform is placed in a consolidation furnace and dried and doped in a gaseous atmosphere at about 1225°C with about 45 vol% He, about 12 vol% Cl 2 , about 32 volume% SiCl 4 and about 11 vol% SiF 4 . The assembly is then transferred (downloaded) through a hot zone with a peak temperature of about 1500°C and a ramp rate of about 2.5°C / min in a gaseous atmosphere with about 44 vol% He, about 41 vol% SiCl 4 and about 15 vol% SiF 4 , resulting in a fully densified Cl and F co-doped silica glass core preform.

[0144] The preform was placed in an Ar purged holding oven set at 1000°C for about 24 hours to degas the He dissolved in the glass. The preform was then placed into a redraw furnace set at about 1900°C. Vacuum was then applied to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com