Device and method for separating sulfur from desulfuration solution

A technology of desulfurization solution and desulfurization liquid, which is applied in the direction of sulfur preparation/purification, etc., can solve problems such as difficulty in meeting the long-term operation requirements of sulfur-containing gas desulfurization devices, pipeline sulfur blockage, and environmental pollution, so as to reduce sulfur blockage and alleviate The effect of load and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

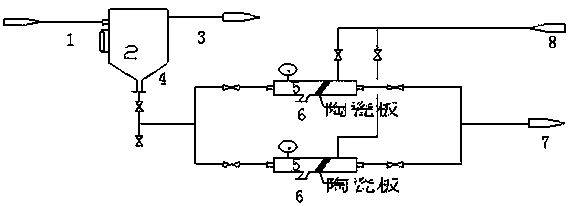

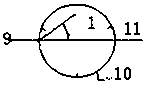

[0021] Device for separating sulfur from desulfurization solution see figure 1 , Mainly includes a cyclone separator 2, a ceramic plate filter 5, conveying equipment and a washing device; the cyclone separator 2 includes a liquid inlet pipe 1, a cyclone separation body 10 and a baffle 11 located inside the cyclone separator The included angle between the inlet pipe 1 of the cyclone separator 2 and the main body 10 of the cyclone separator is 30-80 degrees, and the lower end of the cyclone separator 2 is tapered and connected to the ceramic plate filter 5.

[0022] In the embodiment, the number of the ceramic plate filter 5 is two, the pore diameter of the ceramic plate in the ceramic plate filter is 5-10 microns, and there is a sulfur outlet under the ceramic plate.

[0023] figure 2 It is a cross-sectional schematic diagram of a cyclone separator. 9 is the center line in the figure. The inlet pipe 1 of the cyclone separator and the center line 9 form a 45-degree angle to make the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com