Coral fleece weft-knitted cloth with high hygroscopicity and cleanability and preparation method thereof

A technology with cleanliness and high moisture absorption, applied in weft knitting, dyeing, heating/cooling fabrics, etc., can solve the problems of poor hygroscopicity, poor cleaning performance, uncomfortable use and durability of fiber cleaning cloth, etc., and achieve excellent drape performance, Easy to dry, enhanced cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

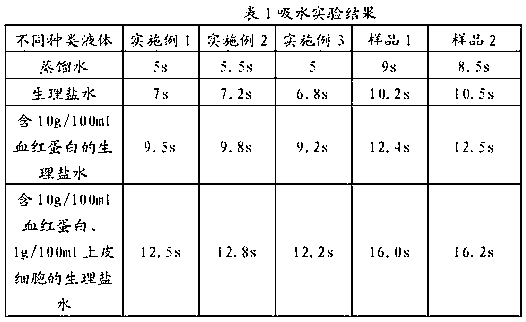

Examples

Embodiment 1

[0032] A coral fleece weft-knitted fabric with high hygroscopicity and high cleanability. The coral fleece weft-knitted fabric is a double-layer structure, including a surface layer and a bottom layer. The surface layer uses 0.52D polyester yarn as the raw material for the fleece yarn, and 100D polyester FDY is The base yarn is made, the mass percentage of polyester yarn in the surface layer is 40%, and the mass percentage of 100D polyester FDY is 60%. The bottom layer of the double-layer blanket is a coral fleece layer, the material of the surface texture is 100D DTY polyester yarn, and the material of the bottom texture is 80D soybean protein fiber silk. The mass percentage of DTY polyester filaments in the bottom layer is 60%, and the mass percentage of soybean protein fiber filaments is 40%. The thickness ratio of the surface layer of the coral fleece weft-knitted cloth to the bottom layer is 1.2:1. The surface suede height is 5mm. The bottom suede height is 4mm.

[003...

Embodiment 2

[0045] A coral fleece weft-knitted fabric with high hygroscopicity and high cleanability, the coral fleece weft-knitted fabric has a double-layer structure, including a surface layer and a bottom layer, and the surface layer uses 0.50D polyester-nylon composite yarn as the raw material of the fleece yarn, and 120D polyester The DTY is made of bottom yarn; the mass percentage of polyester-nylon composite yarn in the surface layer is 60%, and the mass percentage of 120D polyester DTY is 40%. The bottom layer of the double-layer blanket is a coral fleece layer, the material of the surface texture is 140D DTY polyester yarn, and the material of the bottom texture is 100D soybean protein fiber silk. The mass percentage of DTY polyester filaments in the bottom layer is 50%, and the mass percentage of soybean protein fiber filaments is 50%. The thickness ratio of the surface layer of the coral fleece weft-knitted fabric to the bottom layer is 1.6:1.

[0046] The surface suede height...

Embodiment 3

[0059] A coral fleece weft-knitted fabric with high hygroscopicity and high cleaning performance, the coral fleece weft-knitted fabric is a double-layer structure, including a surface layer and a bottom layer, the surface layer uses 0.52D polyester yarn as the raw material of the fleece yarn, and 150D polyester FDY is It is made of bottom yarn; the mass percentage of polyester yarn in the surface layer is 80%, and the mass percentage of 100-150D polyester FDY or DTY is 20%. The bottom layer of the double-layer blanket is a coral fleece layer, the material of the surface texture is 144F DTY polyester yarn, and the material of the bottom texture is 90D soybean protein fiber silk. The mass percentage of DTY polyester filaments in the bottom layer is 40%, and the mass percentage of soybean protein fiber filaments is 60%. The thickness ratio of the surface layer of the coral fleece weft-knitted fabric to the bottom layer is 1.8:1. The surface suede height is 10mm. The bottom sued...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com