Sweeper

A cleaning vehicle and vehicle frame technology, which is applied in the field of cleaning vehicles, can solve problems such as difficult cleaning, reduced dust removal efficiency, and reduced soot blowing efficiency, and achieves the effects of stable filtration efficiency, stable filtration environment, and stable air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

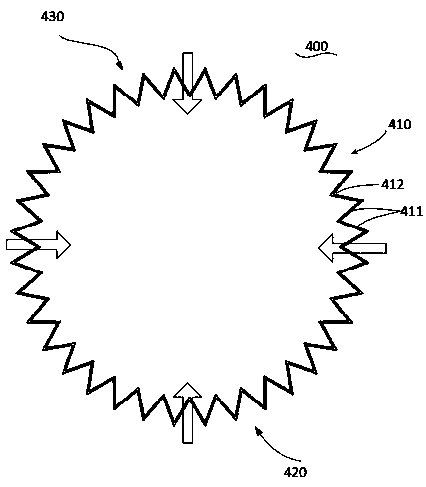

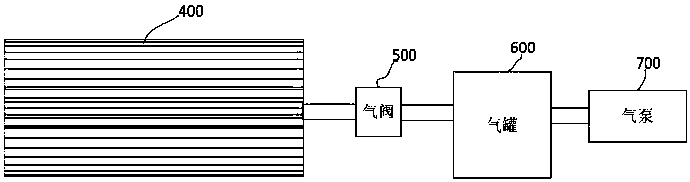

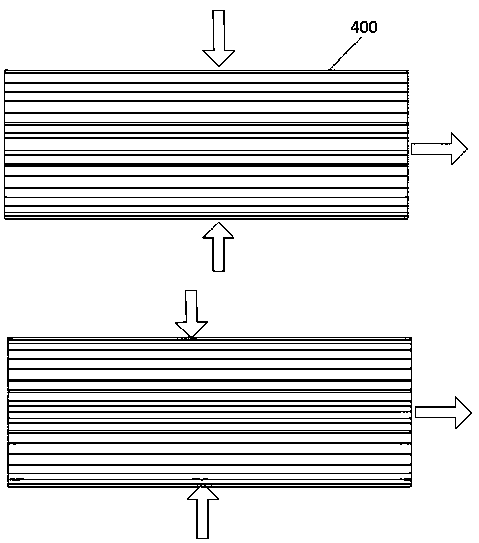

[0031] Figure 5 It is the structural representation of the cleaning vehicle of the present invention; Figure 6 It is the top view structure schematic diagram of the cleaning vehicle of the present invention; Figure 7 It is a schematic diagram corresponding to the first state (online state) in one embodiment of the airway switching device in the present invention; Figure 8 It is a schematic diagram corresponding to the second state (offline state) in one embodiment of the airway switching device in the present invention; Figure 9 It is a structural schematic diagram of another embodiment of the airway switching device in the present invention; Figure 10 It is a schematic top view structure diagram of another embodiment of the airway switching device in the present invention; Figure 11 It is a structural schematic diagram of the bag filter in the present invention; Figure 12 It is a structural schematic diagram of the water filter in the present invention; Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com