Tubular heating furnace with cruciform layout

A tubular heating furnace, cross-shaped technology, applied in the field of cylindrical tubular heating furnace, can solve the problem of easy coking of the medium in the furnace tube, achieve the effect of improving the utilization rate of the furnace tube, reducing the cost of transformation, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

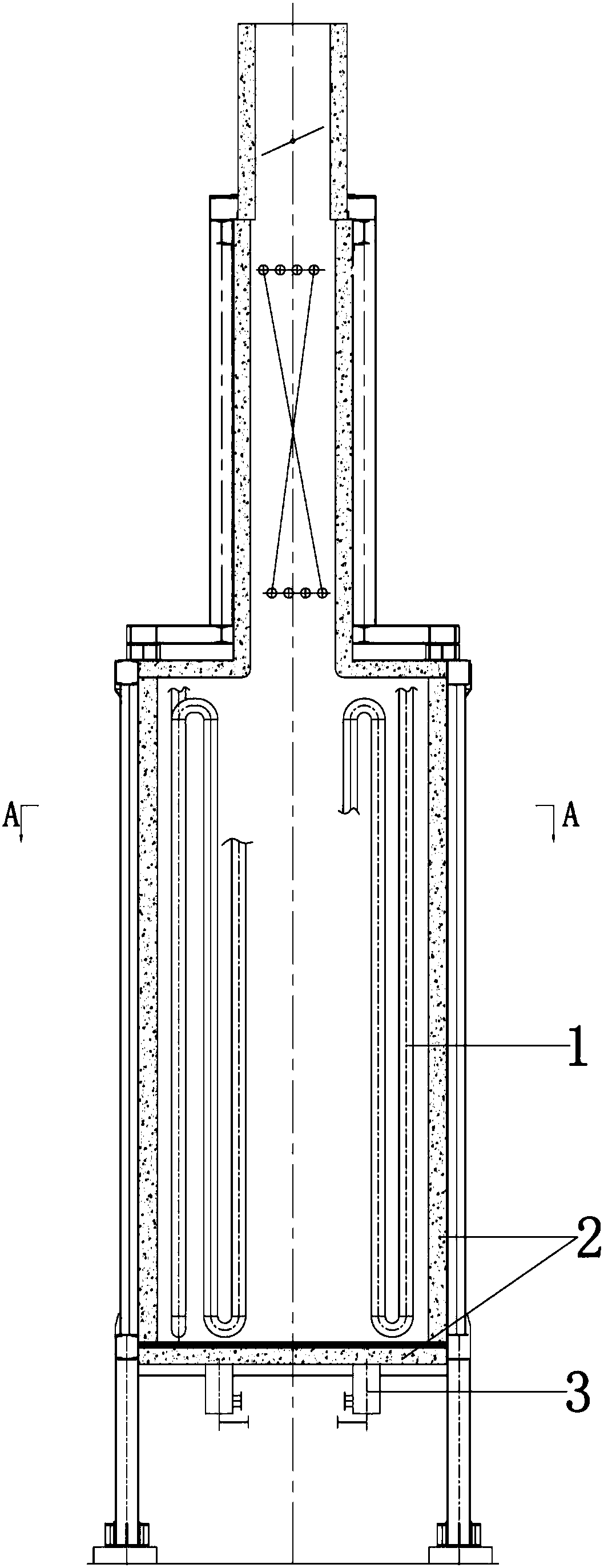

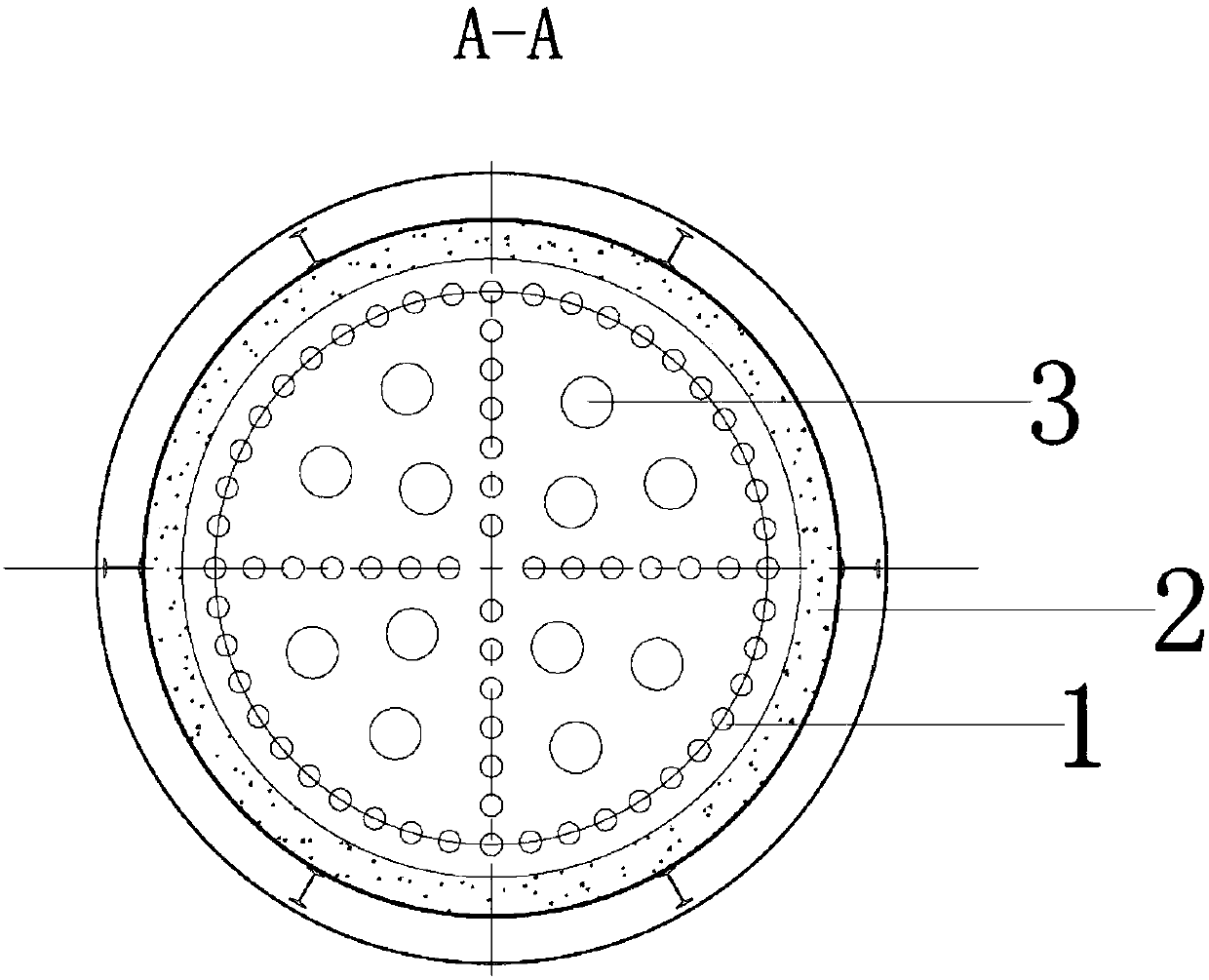

[0018] as attached figure 1 and 2 As shown, the present invention provides a tubular heating furnace with a cross-shaped layout, the heating furnace includes a furnace lining 2, a heater 3 and four furnace tube units, the main body of the furnace lining 2 is a hollow cylindrical structure;

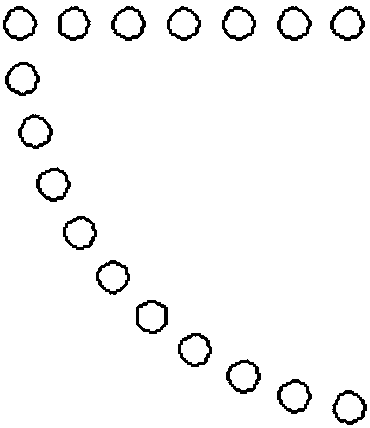

[0019] Furnace tube 1 comprises four furnace tube units, as attached image 3 As shown, the orthographic projection of the furnace tube unit is composed of a quarter circle and a straight line outline, the extension line of the straight line will pass through the center of the circle, and the furnace tube unit is formed by reciprocating up and down according to the direction of the outline line, turning U-shaped structure; the four furnace tube units are arranged inside the furnace lining in sequence, four quarter circles form a complete circle, and four straight lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com