Integrated pressure and temperature sensor

A pressure and sensing device technology, applied in thermometers, measuring fluid pressure, thermometer components, etc., can solve the problems of slow temperature response, hindering heat transfer between fluid medium and temperature sensor, etc., to increase the contact area and improve the response time. effect with precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

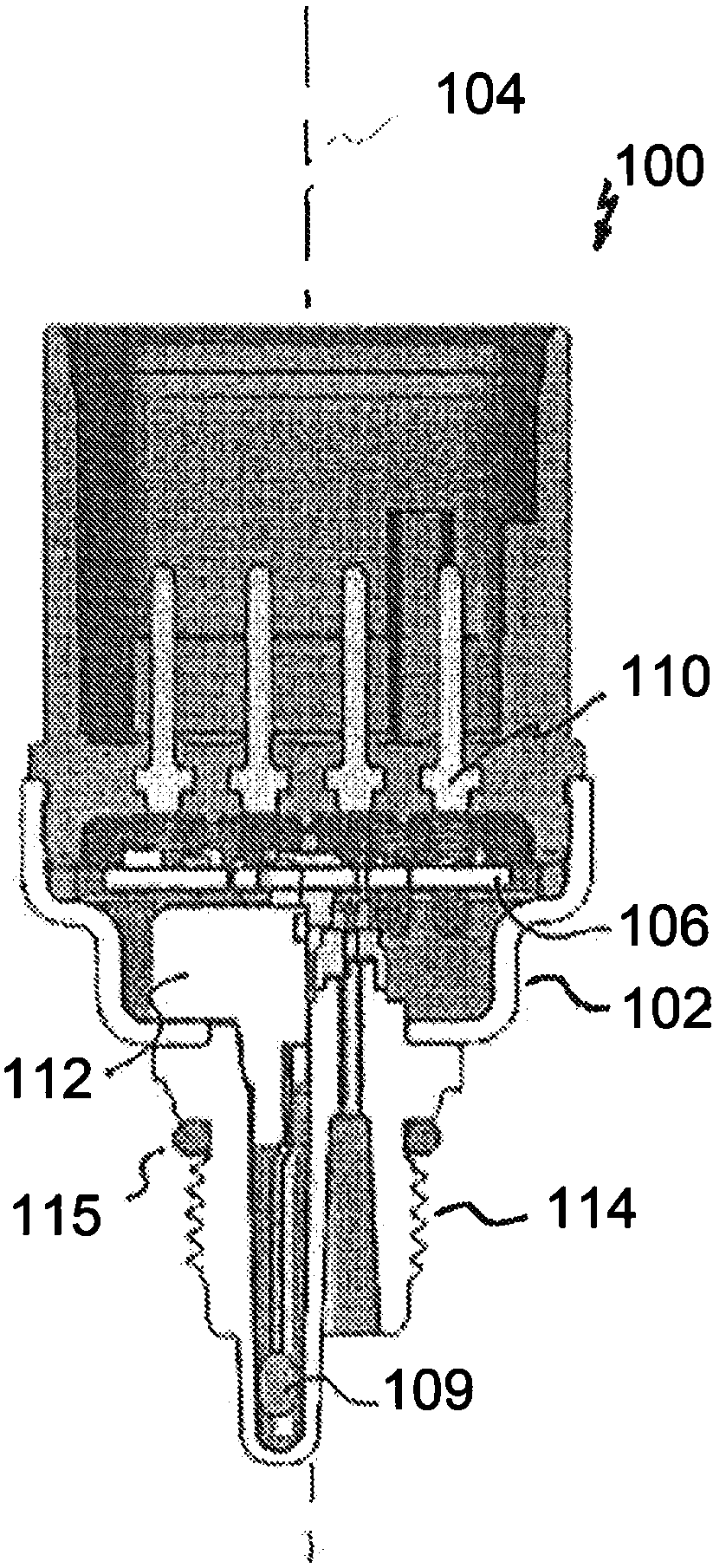

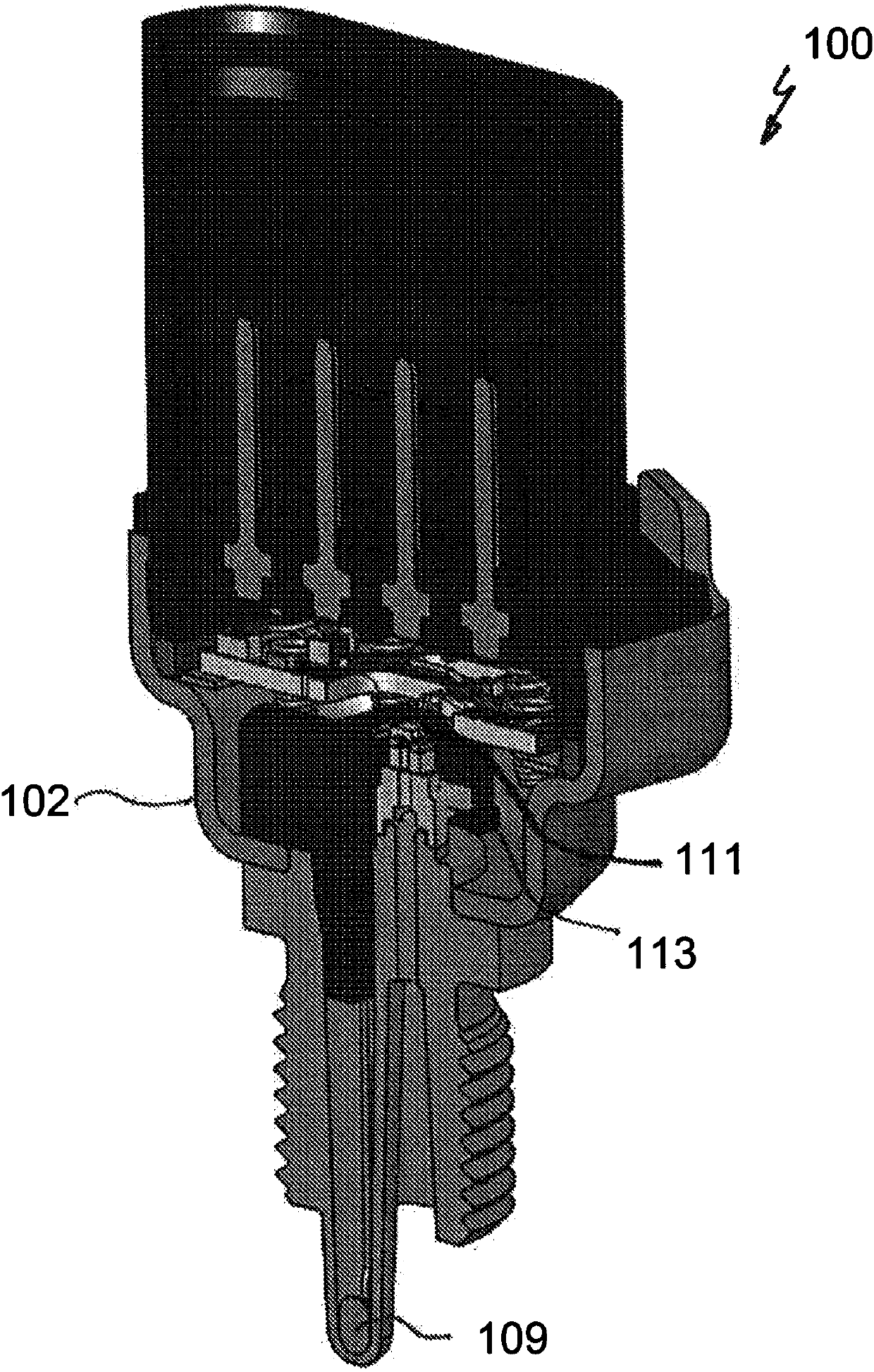

[0016] Aspects of the present disclosure include a combined temperature and pressure sensing device having a sensor port geometry that significantly increases the exposure of the temperature sensor element to the volume of the fluid medium being measured while maintaining the temperature sensor element and pressure sensor element at standard Substantially central positioning within the dimensional constraints of the automotive sensor package. The disclosed temperature and pressure sensing device improves the response time and accuracy of temperature and pressure measurements in mechanical systems such as automotive fuel system applications, for example. A modular construction aspect of a combined temperature and pressure sensing device is disclosed, which facilitates high volume automated assembly techniques.

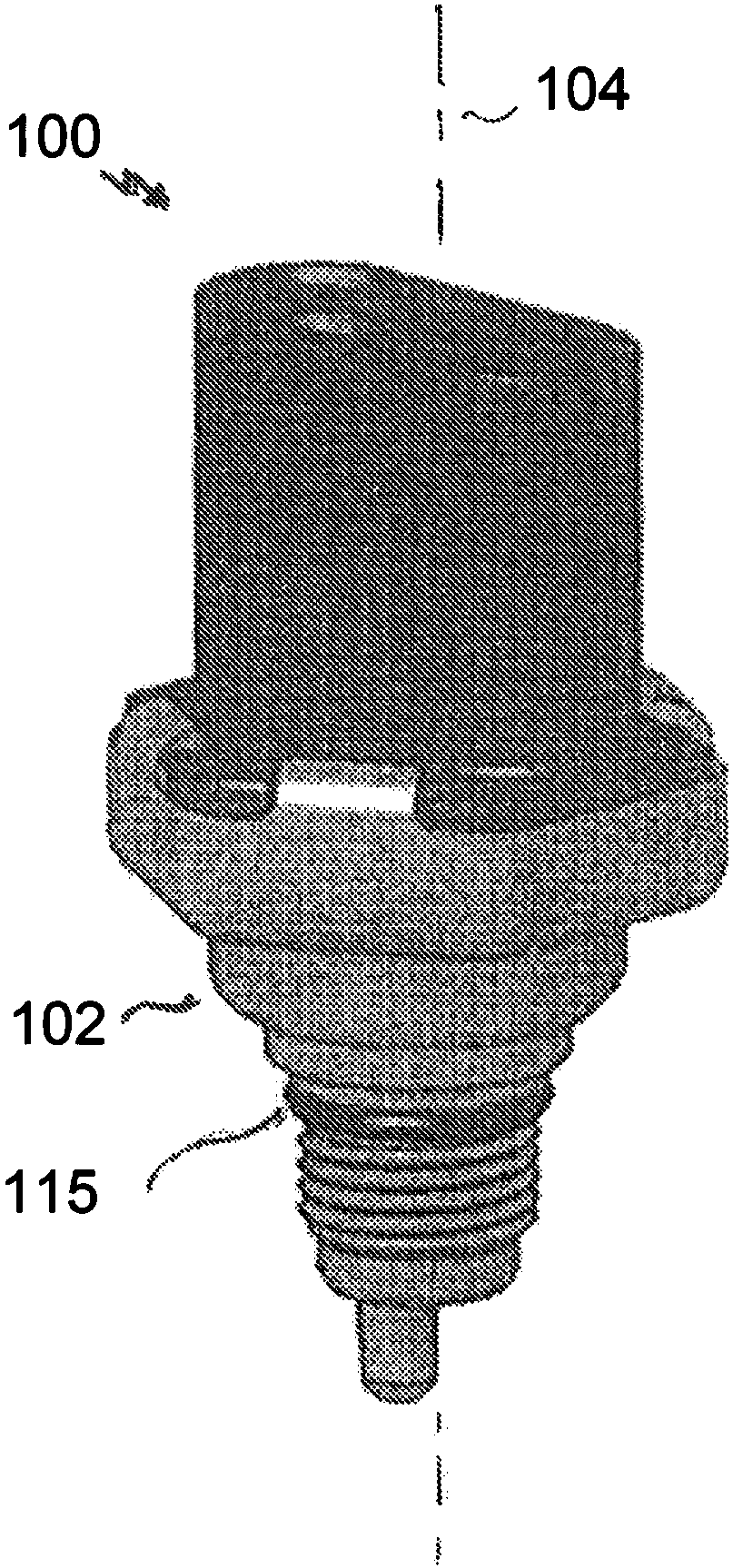

[0017] Figures 1A-1D An example implementation of a combined temperature and pressure sensing device 100 according to aspects of the present disclosure is shown. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com