Method for hoisting core and shell of high temperature gas cooled reactor

A technology for high-temperature gas-cooled reactors and hoisting methods, which is applied to reactors, reactor fuel elements, and greenhouse gas reduction. It can solve problems such as difficult construction, difficult turning, and easy collisions and scratches, so as to improve hoisting quality and safety. performance, improving construction safety, avoiding collisions and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

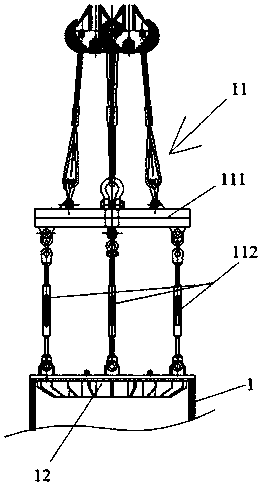

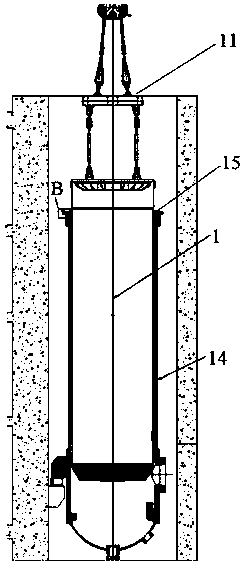

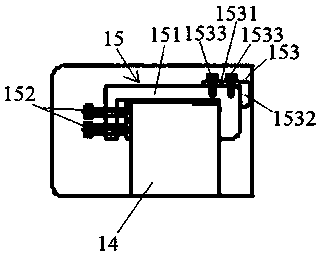

[0036] Below, in conjunction with Figure 1-13 The method for hoisting the core shell of the high-temperature gas-cooled reactor of the present invention will be described in detail.

[0037] An overturning bracket 2 for supporting the core shell 1 and a lower load-bearing support 3 and an upper fixed inclined support 4 for supporting the erection of the core shell 1 are fixedly installed at the construction site.

[0038] Such as figure 1 with 2 As shown, the turning bracket 2 includes a support base 21 and a vertical support rod 22. The support base 21 and the vertical support rod 22 are vertically connected to form a T-shaped frame. The vertical support rod 22 is provided with connecting vertical support rods 22 and The reinforced diagonal brace 23 of the supporting bottom plate 21 is supported, and the top end of the vertical brace 22 is provided with a supporting groove. Preferably, as image 3 with 4 As shown, the fixed tooling 5 is used to fix the turning bracket 2. The fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com