Spray emulsion composition and preparation method thereof

A composition and extract technology, applied in the field of skin care products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

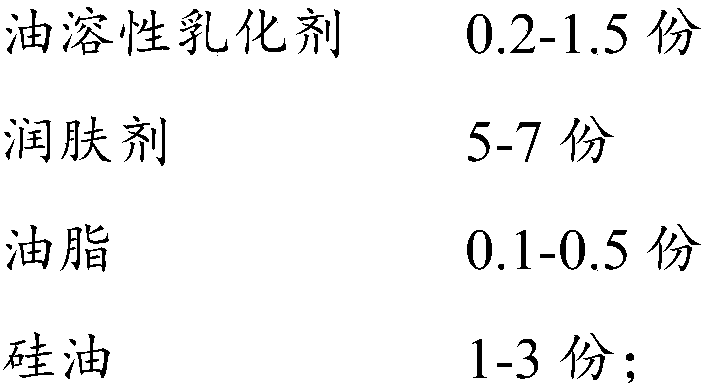

[0041] A spray milk composition, comprising the following components:

[0042]

[0043] The preparation method of above-mentioned spray milk composition, comprises the steps:

[0044] Heat oil phase A to 80-85°C, stir until completely dissolved;

[0045] Pre-disperse the water and emulsifier in the water phase B, then add other materials in the water phase B, heat up to 80-85°C, and stir until completely dissolved;

[0046] Add oil phase A to water phase B (stop stirring) and homogenize for 4-6 minutes, stir at constant temperature for 15-25 minutes, and cool down;

[0047] Cool down to 45°C and add phase C to adjust the pH value, then add phase D (D is pre-mixed and dissolved before adding) and stir evenly to obtain the spray milk composition.

Embodiment 2

[0049] A spray milk composition, comprising the following components:

[0050]

[0051] The preparation method of above-mentioned spray milk composition, comprises the steps:

[0052] Heat oil phase A to 80-85°C, stir until completely dissolved;

[0053] Pre-disperse the water and emulsifier in the water phase B, then add other materials in the water phase B, heat up to 80-85°C, and stir until completely dissolved;

[0054] Add oil phase A to water phase B (stop stirring) and homogenize for 4-6 minutes, stir at constant temperature for 15-25 minutes, and cool down;

[0055] Cool down to 45°C and add phase C to adjust the pH value, then add phase D (D is pre-mixed and dissolved before adding) and stir evenly to obtain the spray milk composition.

Embodiment 3

[0057] A spray milk composition, comprising the following components:

[0058]

[0059] The preparation method of above-mentioned spray milk composition, comprises the steps:

[0060] Heat oil phase A to 80-85°C, stir until completely dissolved;

[0061] Pre-disperse the water and emulsifier in the water phase B, then add other materials in the water phase B, heat up to 80-85°C, and stir until completely dissolved;

[0062] Add oil phase A to water phase B (stop stirring) and homogenize for 4-6 minutes, stir at constant temperature for 15-25 minutes, and cool down;

[0063] Cool down to 45°C and add phase C to adjust the pH value, then add phase D (D is pre-mixed and dissolved before adding) and stir evenly to obtain the spray milk composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com