Milling cutter system

A milling cutter and cutting tool technology, applied in the field of milling machine devices, can solve the problems of difficulty in ensuring the accuracy and high efficiency of the gun barrel rifling, rough surface of the female rifling with knife marks, large internal ballistic resistance, etc., and achieves strong flexibility and surface quality. Good, low ballistic resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

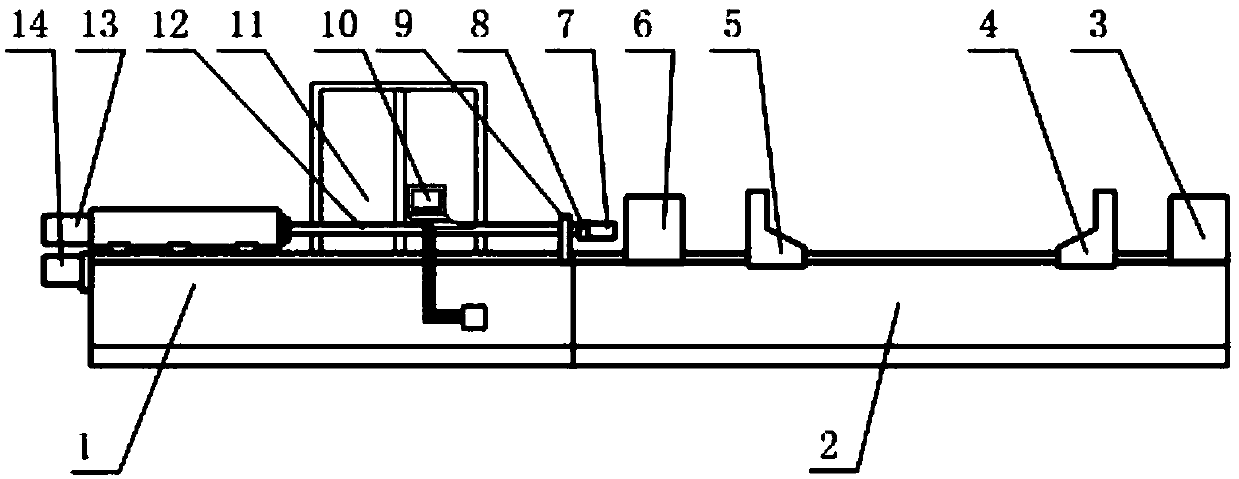

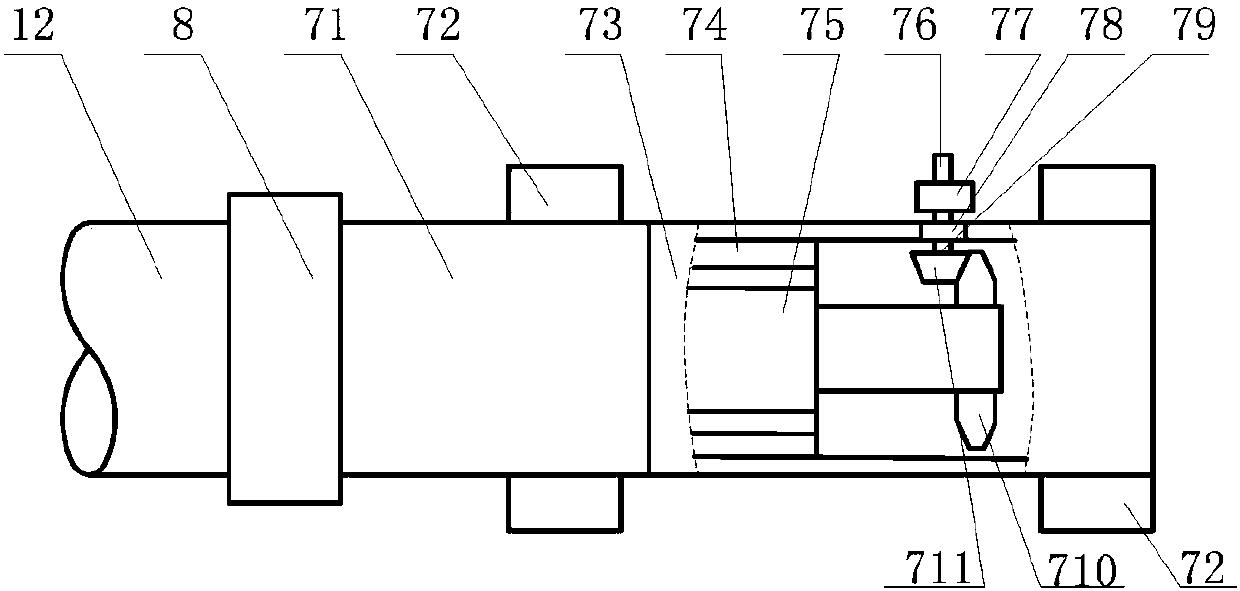

[0027] This embodiment provides a milling cutter system, comprising:

[0028] The bed 1 of the machine tool spindle is used to support the milling parts of the workpiece. The bed is provided with a roller linear guide for guiding during the milling process;

[0029] The machine tool spindle bed 1 is connected with a barrel bed 2, and the barrel bed 2 is used for barrel positioning and support for clamping parts, and a dovetail guide rail is set;

[0030] The body tube bed 2 is slidably connected with a front bracket 5, a rear bracket 4, a front fuel tank 6, and a rear fuel tank 3; wherein: the front bracket 5 and the rear bracket 4 are respectively fixedly connected with self-centering chucks for The positioning and clamping of barrel parts, the front oil tank 6 and the rear oil tank 3 are used for splash prevention and recovery of cooling oil;

[0031] The machine tool spindle bed 1 is connected with a fixed guide frame 9 and an operating table 10, the fixed guide frame 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com