Chip discharging structure of machine tool

A machine tool and chip flute technology, which is used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. The effect of increasing the chip evacuation space, improving the smoothness of chip evacuation and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

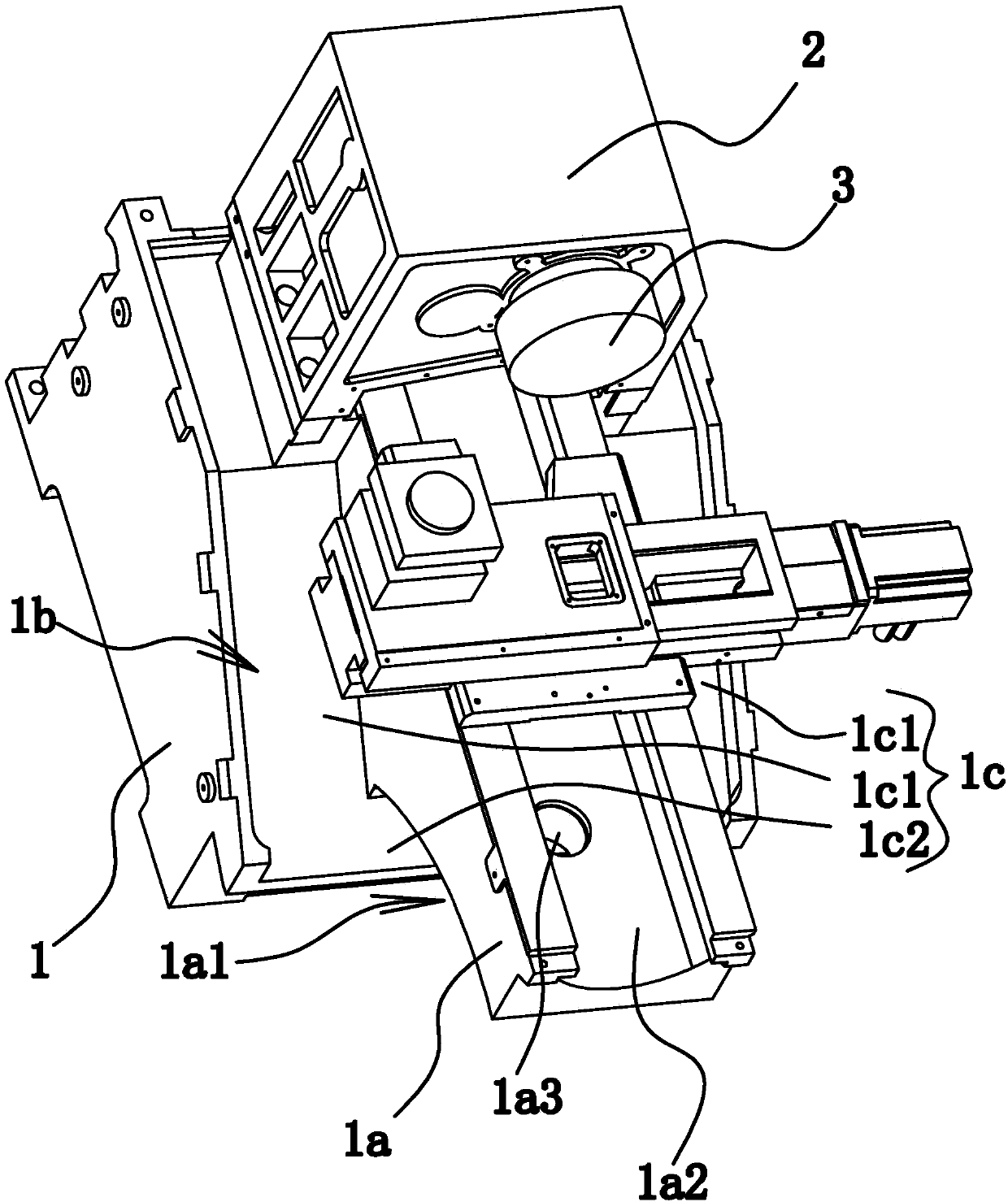

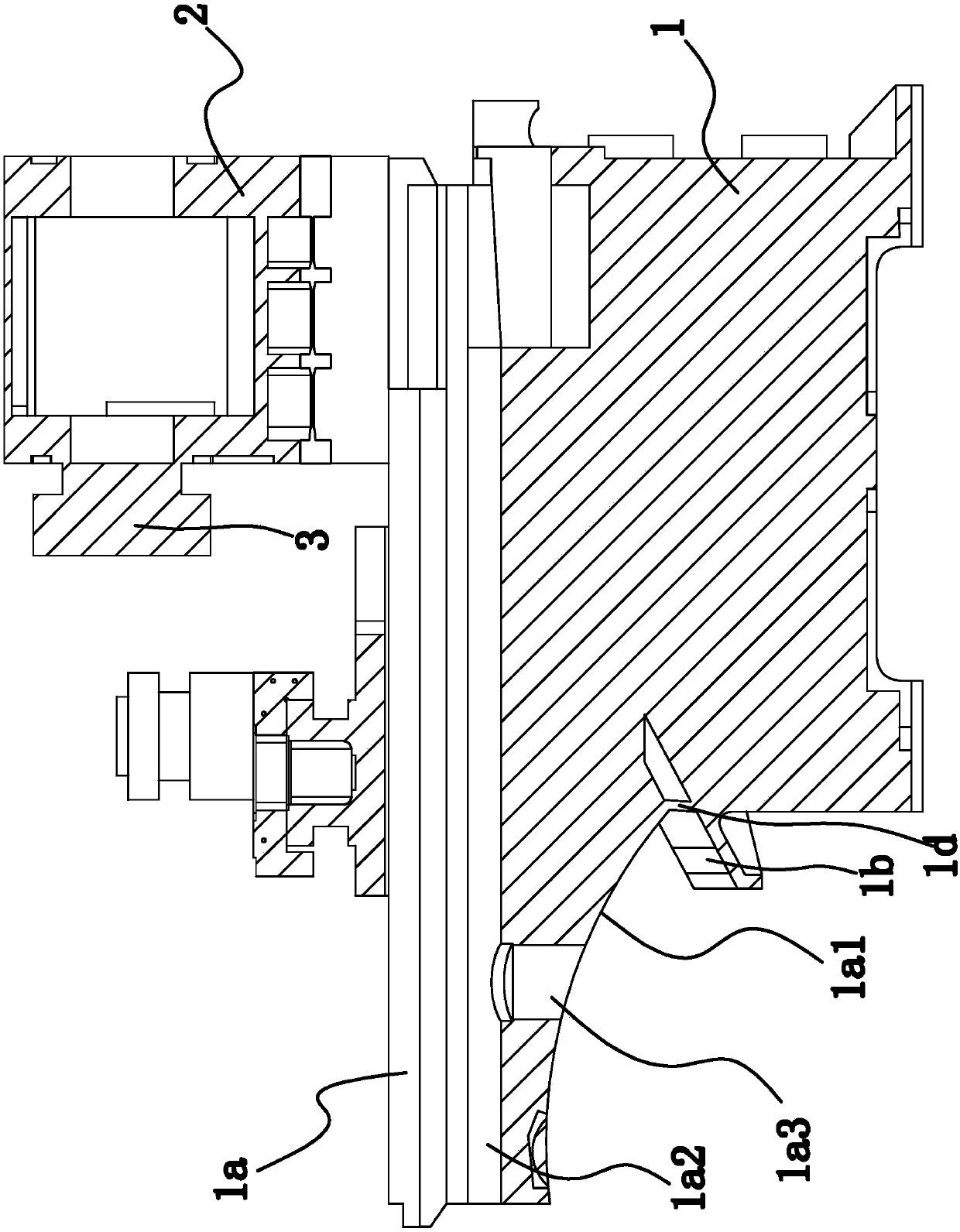

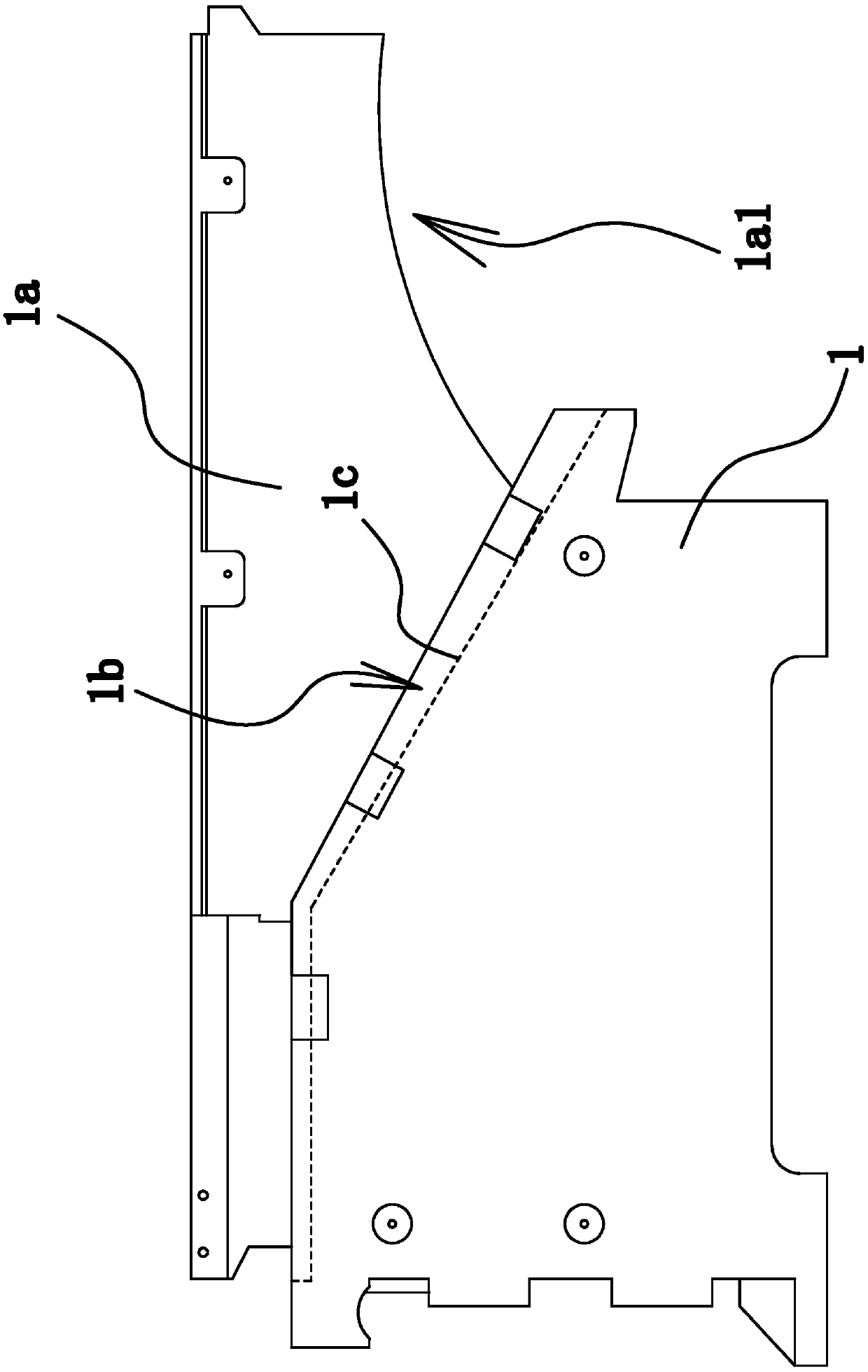

[0020] Such as Figure 1 to Figure 3 As shown, the machine tool includes a bed 1 and a headstock 2 arranged on the bed 1 , and a spindle 3 is installed on the headstock 2 . One side of the headstock 2 is provided with a strip-shaped installation platform 1a, and the installation platform 1a and the bed 1 are integrally structured. The mounting table 1 a is located directly below the main shaft 3 , and the length of the mounting table 1 a extends along the axial direction of the main shaft 3 . In actual use, the installation table 1a is used for installing guide rails.

[0021] Such as figure 1 and image 3 As shown, the chip removal structure includes a chip removal groove 1b provided on the bed 1, and the lower side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com