An electric power-assisted braking system based on a dual-rotor motor

A dual-rotor motor, electric power assist technology, applied in the direction of brakes, electric components, brake transmission devices, etc., can solve the problems of coupling and decoupling of the braking force of the driver and the electric motor braking force, etc., to facilitate the layout and structure of the actual vehicle. Simple, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

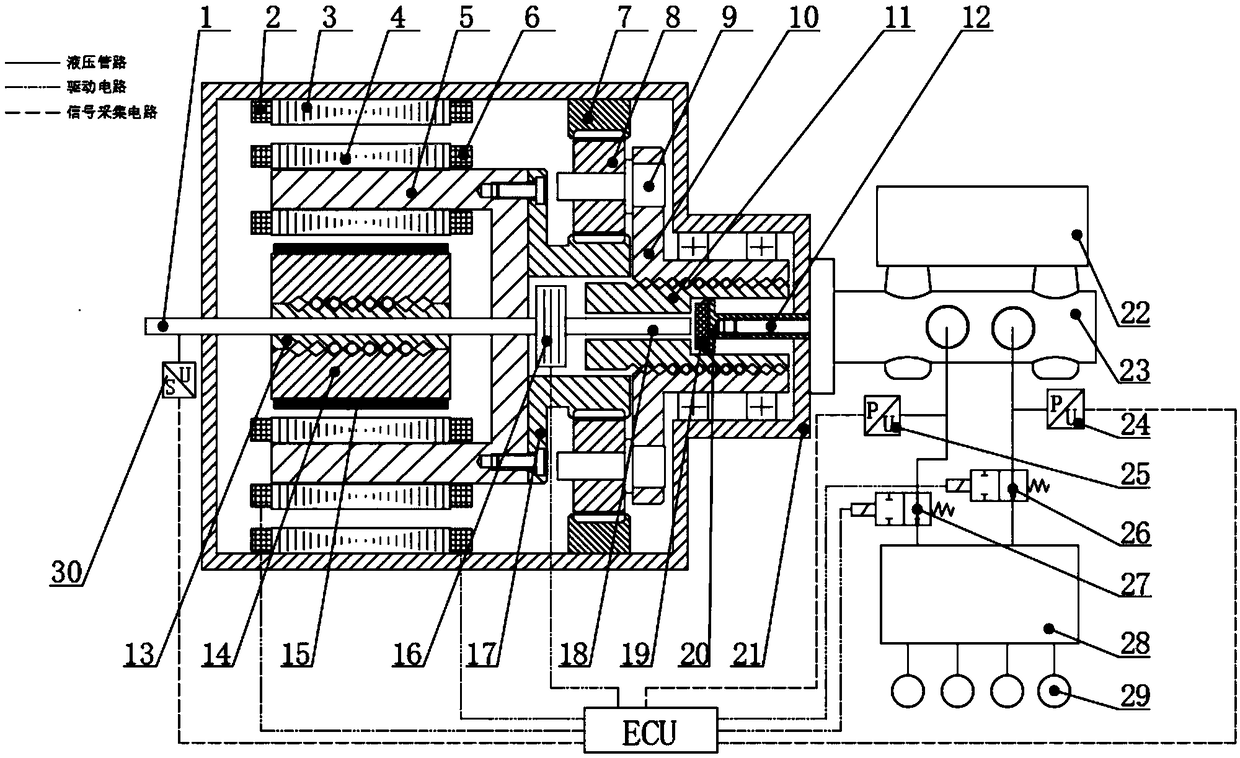

[0030] The present invention is described below in conjunction with accompanying drawing:

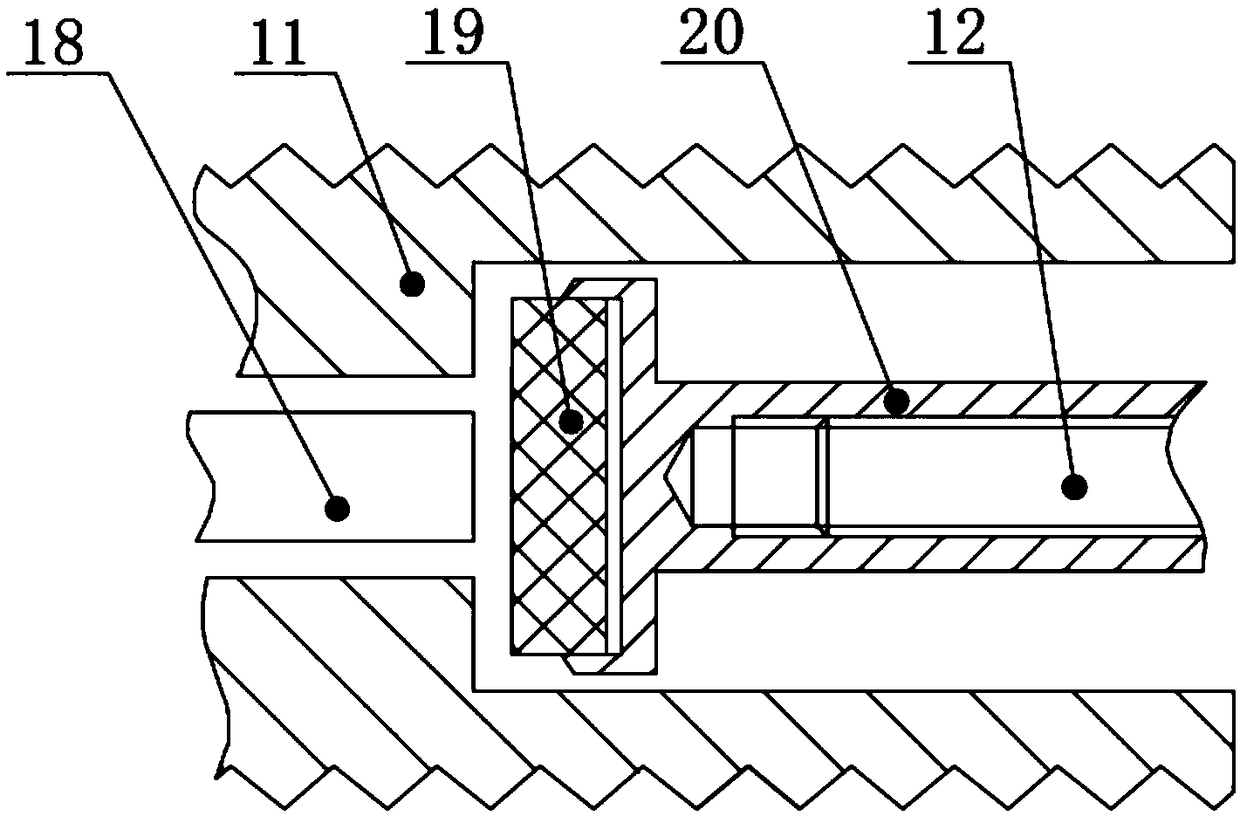

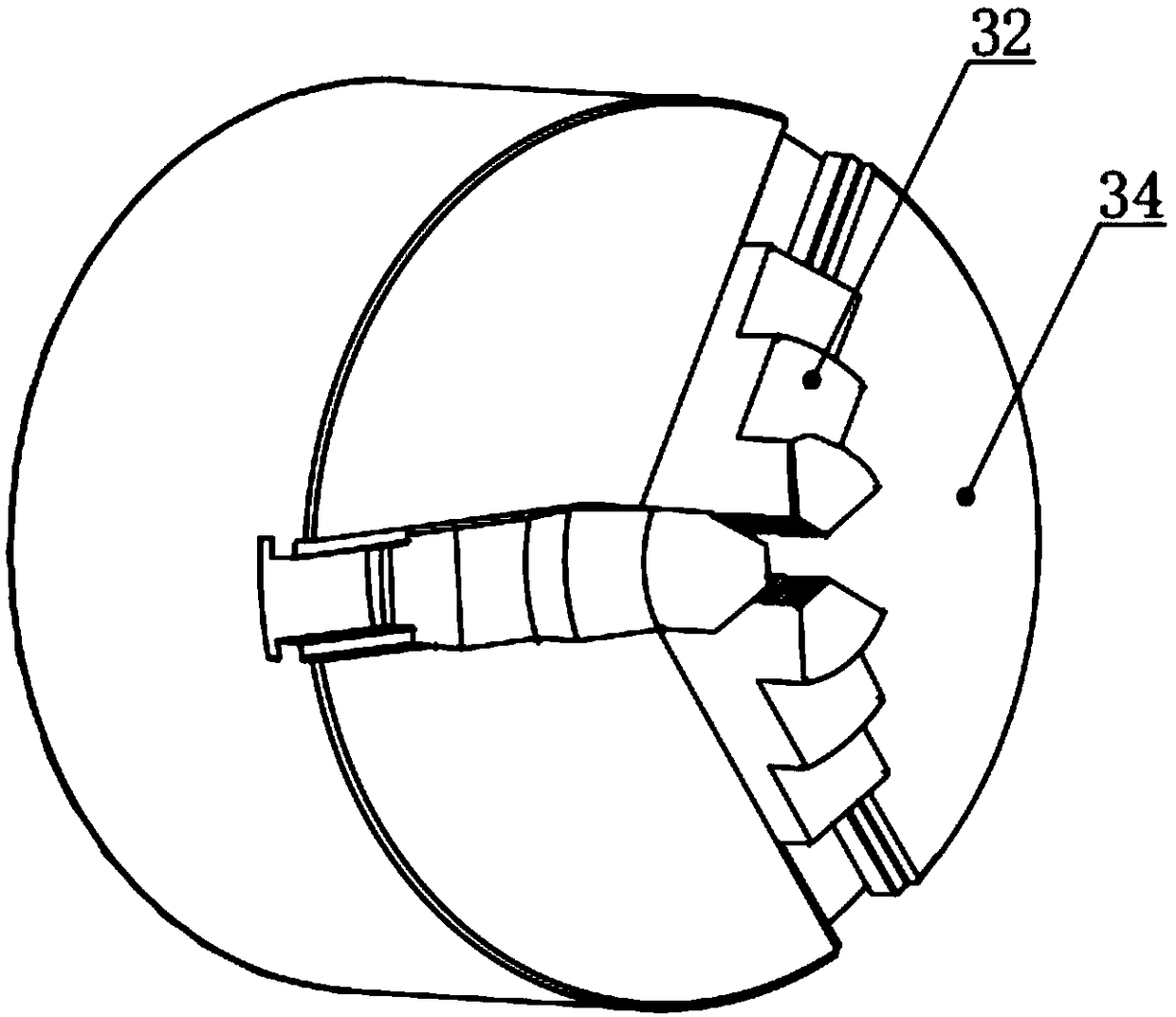

[0031] refer to figure 1 , a kind of electric power-assisted braking system based on double-rotor motor described in the present invention, comprises a housing 21, with the driver's braking force input direction as the front, the housing 21 is provided with a motor inside, and the motor includes a motor with a stator The cross section of the winding 2 is a circular stator core 3, a circular outer rotor core 4 with an outer rotor winding 6 and an inner rotor core 14, and a circular cross section is fixedly mounted on the inner side of the front part of the housing 21. Annular stator core 3 . The stator winding 2 is mounted on the stator core 3 . The middle part of the front end face of the housing 21 has a circular through hole, and the front part of a circular No. 1 push rod 1 with an equal section passes through the circular through hole on the front end face of the housing 21. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com