Inner packing equipment for flour processing and packing

A technology for inner packaging and flour, applied in packaging, transportation packaging, packaging protection, etc., to achieve the effects of reducing labor intensity, reducing airflow interference, and reducing operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

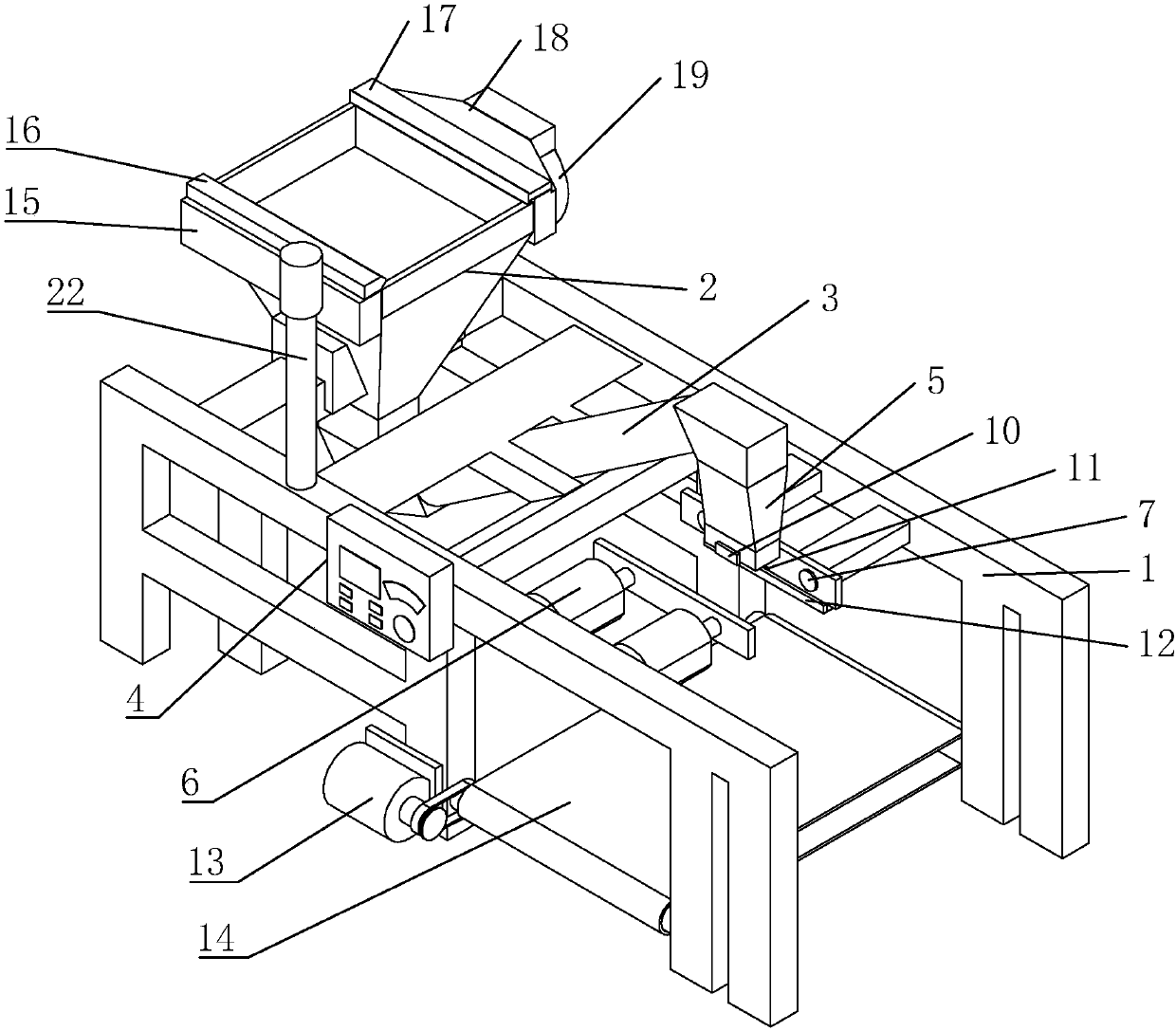

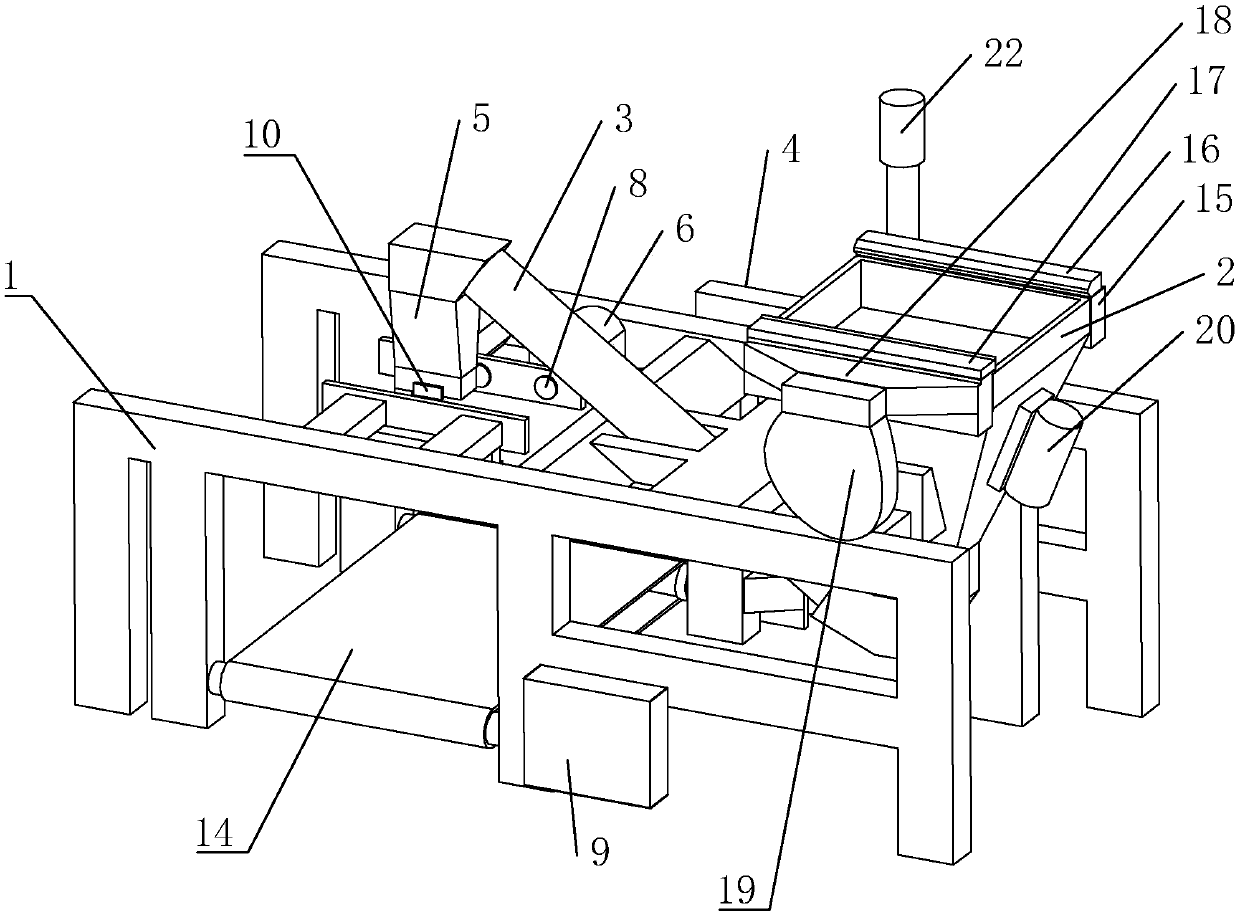

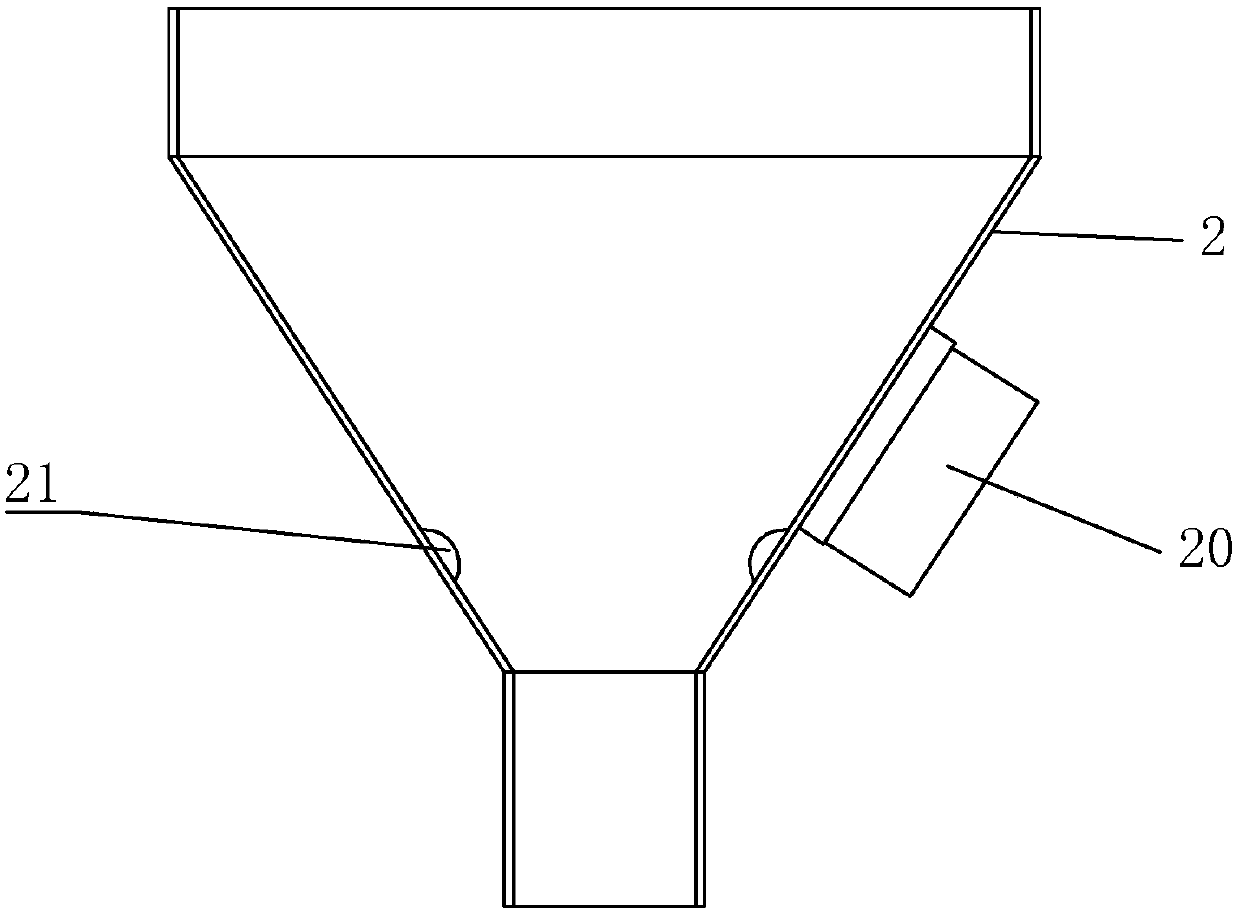

[0023] refer to Figures 1 to 3 As shown, an inner packaging device for flour processing and packaging in this embodiment includes a frame 1, a hopper 2, a conveying auger 3, a controller 4, a discharge cylinder 5, a cylinder 6, a first suction cup 7, a second Two suction cups 8, air suction pump 9, first detection sensor 10, second detection sensor 11, sealing device 12, transmission device and air curtain device, described hopper 2 is installed on the frame 1, and described delivery auger 3 is installed on On the frame 1, and the conveying auger 3 is inclined, the outlet position of the conveying auger 3 is higher than the inlet position, and the inlet of the conveying auger 3 is connected to the lower end opening of the hopper 2,

[0024] The upper end of the discharge cylinder 5 is connected to the outlet of the conveying auger 3, and the discharge cylinder 5 is vertically arranged, and the first suction cup 7 is fixed on the frame 1, and the first suction cup 7 is positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com