Preservation method of dried cocoons

A preservation method and cocoon technology, which is applied in silk fiber production, textiles and papermaking, mechanical treatment, etc., can solve the problems of being vulnerable to grain robbery and cocoon mildew, etc., to avoid high temperature drying, strong surface adsorption, and shape retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

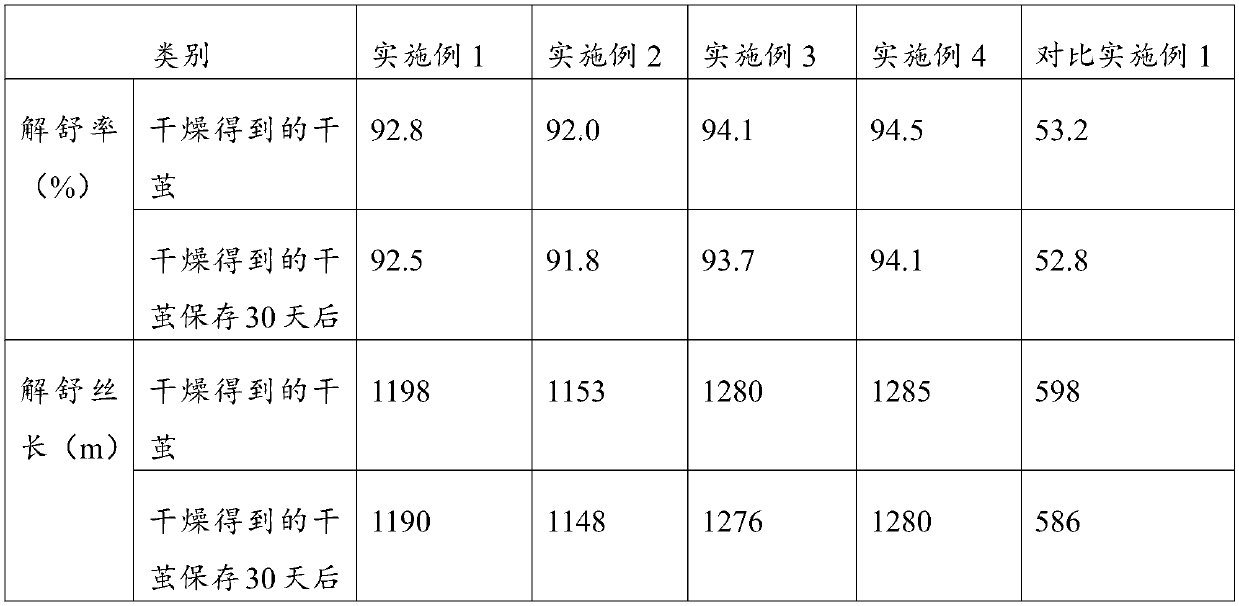

Examples

Embodiment 1

[0025] A method for preserving dry silkworm cocoons, comprising the following steps:

[0026] (1) Freeze the silkworm cocoons for 3 hours at -26°C, vacuumize to 10Pa, and dry until the water content of the silkworm cocoons is 10%; put the dried silkworm cocoons into a 0.10mm thick polyethylene film bag, And put the desiccant in the polyethylene film bag, and then tie the bag tightly;

[0027] (2) After the storage is treated with pyrethroid insecticides for disinsection, ventilate and dry, then control the temperature of the storage to be 20°C and the relative humidity to be 55%;

[0028] (3) Move the packaged dried silkworm cocoons into the storage warehouse treated in step (2). During the whole storage period, the temperature of the storage warehouse is controlled at 20° C. and the relative humidity is 55%, until the storage ends.

[0029] The desiccant is packaged in a breathable material packaging bag, and the desiccant is mixed by the following raw materials in parts by ...

Embodiment 2

[0032] A method for preserving dry silkworm cocoons, comprising the following steps:

[0033] (1) Freeze the silkworm cocoons for 4 hours at -18°C, vacuumize to 15Pa, and dry until the water content of the silkworm cocoons is 12%; put the dried silkworm cocoons into a 0.12mm thick polyethylene film bag, And put the desiccant in the polyethylene film bag, and then tie the bag tightly;

[0034] (2) After the storage is treated with pyrethroid insecticides for disinsection, ventilate and dry, then control the temperature of the storage to be 25°C and the relative humidity to be 60%;

[0035] (3) Move the packaged dried silkworm cocoons into the storage warehouse treated in step (2). During the whole storage period, the temperature of the storage warehouse is controlled at 25° C. and the relative humidity is 60%, until the storage ends.

[0036] The desiccant is packaged in a breathable material packaging bag, and the desiccant is mixed by the following raw materials in parts by ...

Embodiment 3

[0039] A method for preserving dry silkworm cocoons, comprising the following steps:

[0040] (1) After freezing the silkworm cocoons for 3 hours at -26°C, put the pre-frozen silkworm cocoons into a microwave vacuum drying oven, vacuumize to 5Pa, microwave frequency is 100MHz, and dry until the moisture content of the silkworm cocoons is 10%; Pack the dried silkworm cocoons into a 0.10mm thick polyethylene film bag, put desiccant in the polyethylene film bag, and then tie the bag tightly;

[0041] (2) After the storage is treated with pyrethroid insecticides for disinsection, ventilate and dry, then control the temperature of the storage to be 20°C and the relative humidity to be 55%;

[0042] (3) Move the packaged dried silkworm cocoons into the storage warehouse treated in step (2). During the whole storage period, the temperature of the storage warehouse is controlled at 20° C. and the relative humidity is 55%, until the storage ends.

[0043] The desiccant is packaged in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com