Compression-shear testing device of structural strength and fatigue of composite pavement

A composite pavement and structural strength technology, which is applied in the direction of measuring devices, strength characteristics, and preparation of test samples, can solve the problems of composite pavement structures that lack structural strength and fatigue performance evaluation methods, and achieve easy promotion and use. Scientific and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

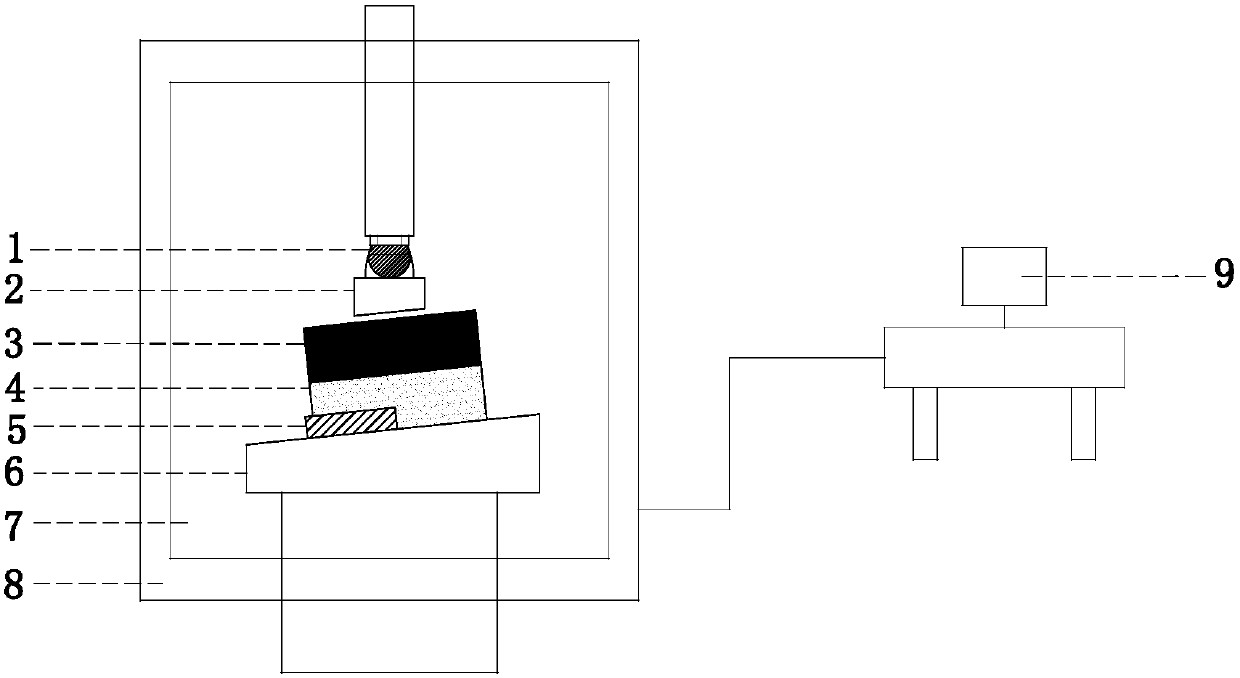

[0029] Self-made double-layer rut slab test mold, this embodiment takes the semi-rigid base layer flexible surface composite pavement structure sample formed in the room as an example to illustrate, and other composite structure test samples are analogous. Specific steps are as follows:

[0030] (1) Preparation of the base layer of the composite specimen, pouring a semi-rigid inorganic bonding stable material in the lower rutting plate test mold, vibrating and compacting it and placing it for 45 minutes, then performing grooved roughening on the upper surface, and putting it into a standard health care room for health preservation After 7 days, take it out of the health care room after its unconfined compressive strength meets the specification requirements.

[0031] (2) The adhesive layer is made to ensure that the surface of the semi-rigid base is dry and clean, and the upper surface is 1.4kg / m 3 Evenly spread SBS modified asphalt, and immediately continue to evenly spread ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com