A single-stage boost inverter and its control method

An inverter and single-stage technology, which is applied in the field of single-stage boost inverter and its control, can solve the problems of reducing inverter efficiency, high performance requirements of switching devices, and low DC bus voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

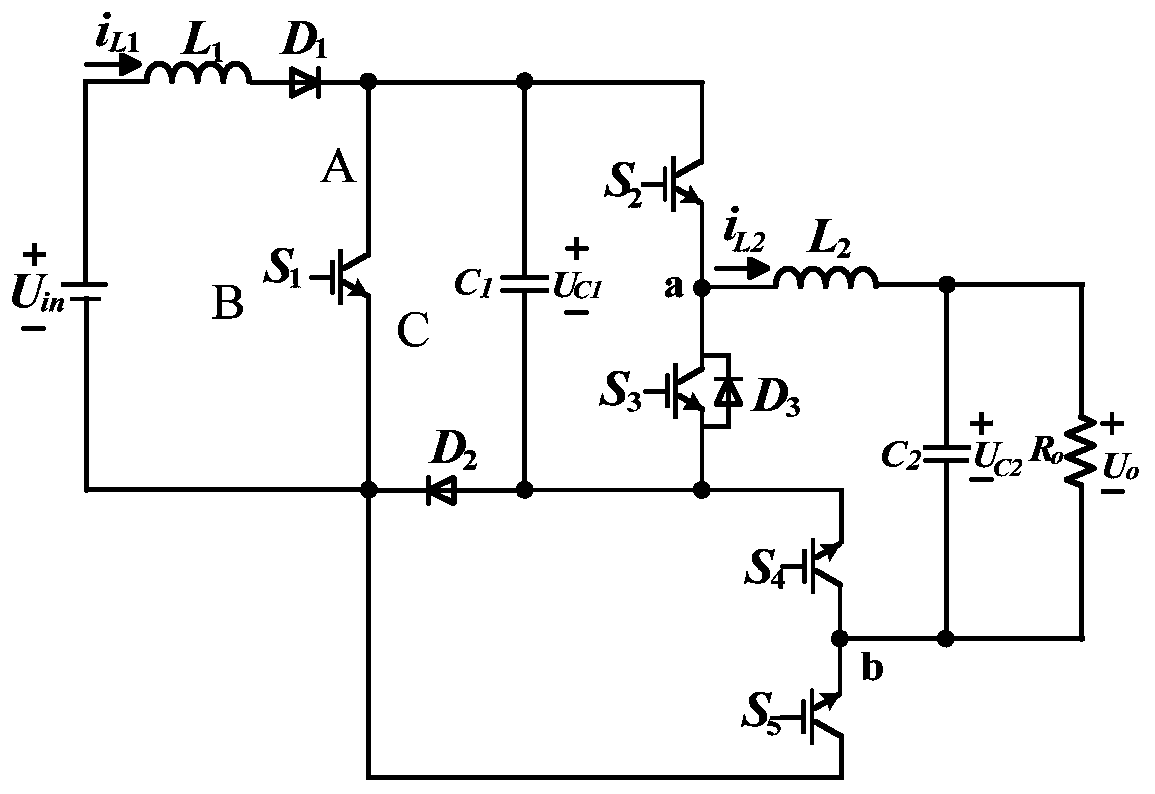

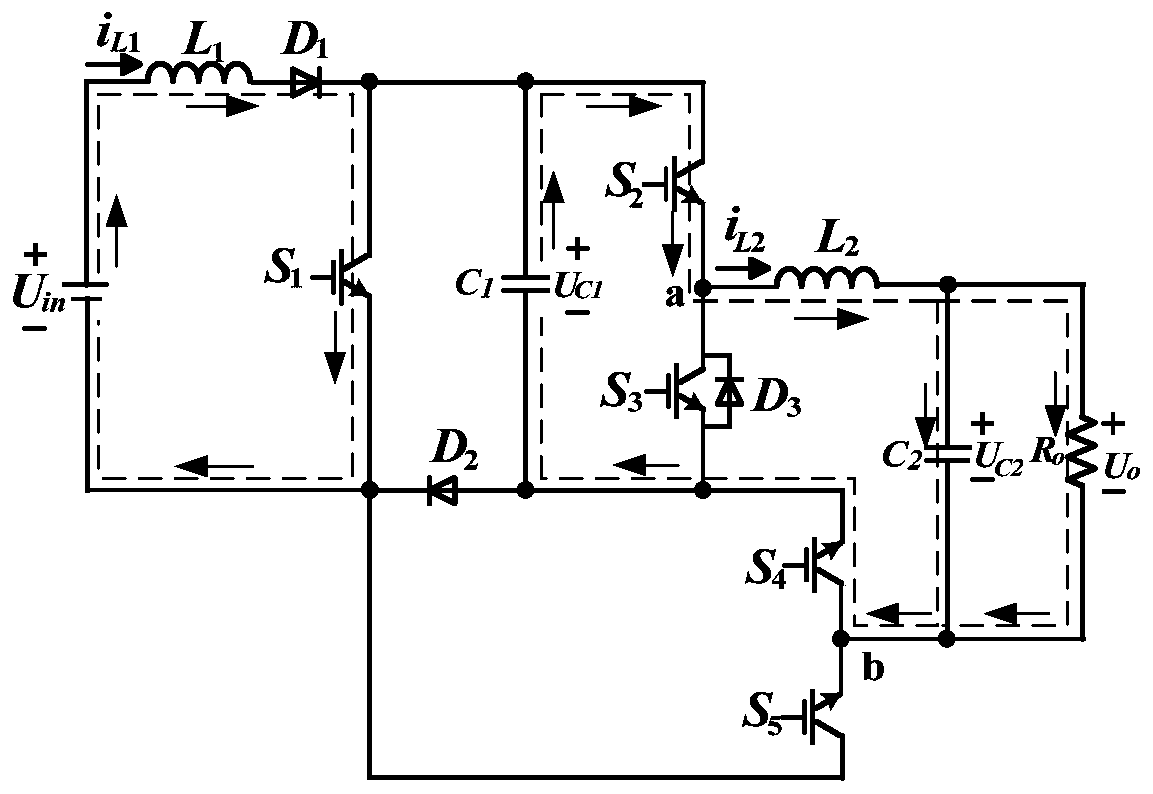

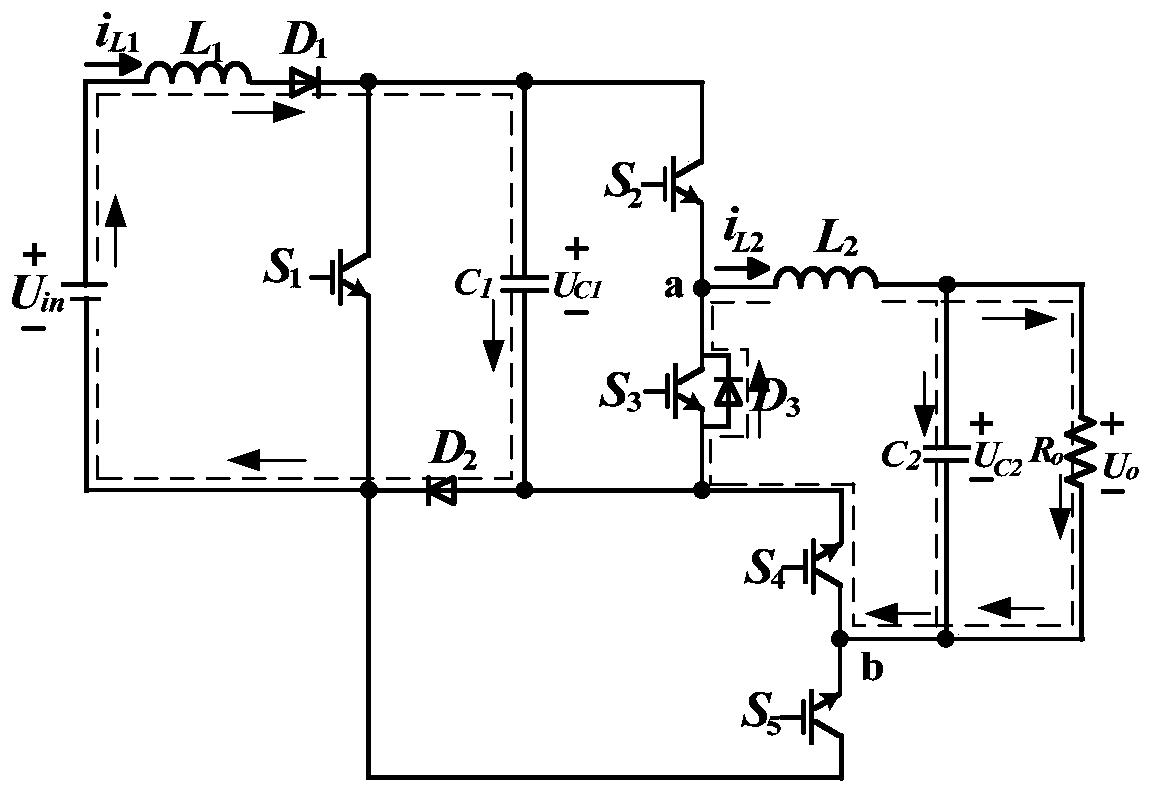

[0068] Such as Figure 1-7 , a single-stage boost inverter, including a power switch S 1, S 2 , S 3 , S 4 and S 5 , Diode D 1 、D 2 、D 3 , inductance L 1 and capacitance C 1 ; Inductance L 1 One end is connected to the other end of the input power supply Uin, and the inductance L 1 The other end is connected to the diode D 1 anode connected; diode D 1 The cathodes are respectively connected to the power switch tube S 1 Terminal A, power switch tube S 2 A terminal and capacitor C 1 One end; diode D 2 The anode is connected to the capacitor C 1 The other end, the power switch tube S 3 and S 4 C terminal, diode D 3 anode; diode D 2 The cathode is connected to the power switch tube S 1 The C terminal of the power switch tube S 5 A terminal and input power U in The other end; diode D 3 Cathode, power switch tube S 2 The C terminal and the power switch tube S 3 Terminal A of A is connected to node a; the power switch tube S 4 A terminal and the power switch...

Embodiment 2

[0071] Such as Figure 1-7 , a single-stage boost inverter of this embodiment, on the basis of Embodiment 1, also includes a filter, the nodes a and b are connected to the input end of the filter, and the output end of the filter is connected to the load R O connection, further, in this embodiment, the filter is LC type, including filter inductor L 2 and filter capacitor C 2 , filter inductance L 2 One end is connected to node a, and the filter inductor L 2 The other end is connected to the filter capacitor C 2 One end and grid or load R O Connected at one end, the filter capacitor C 2 The other end and the grid or load R O The other end is connected to node b.

[0072] In this embodiment, the step-up inverter is completed, and the output terminal of the filter, that is, the output voltage u o directly for the load R o power supply, or the output voltage u o Feedback to the grid.

[0073] This embodiment also includes a control method for a single-stage boost inver...

Embodiment 3

[0124] A single-stage boost inverter in this embodiment has the same basic structure as that in Embodiment 1 or 2, and further, because the capacitor C 1 As an energy storage element, it plays the role of energy conversion, and the capacitor C 1 It is a non-polar capacitor, which makes the circuit work reliably and increases the working life of the circuit; the control method of a single-stage boost inverter in this embodiment is the same as that in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com