Installation method for gantry structure of large-sized gantry machine tool

A technology of gantry machine tools and installation methods, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of expensive laser interferometers, low verticality accuracy of X-axis guide rails, etc., to shorten the installation time, Reduce the dependence on quality and improve the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

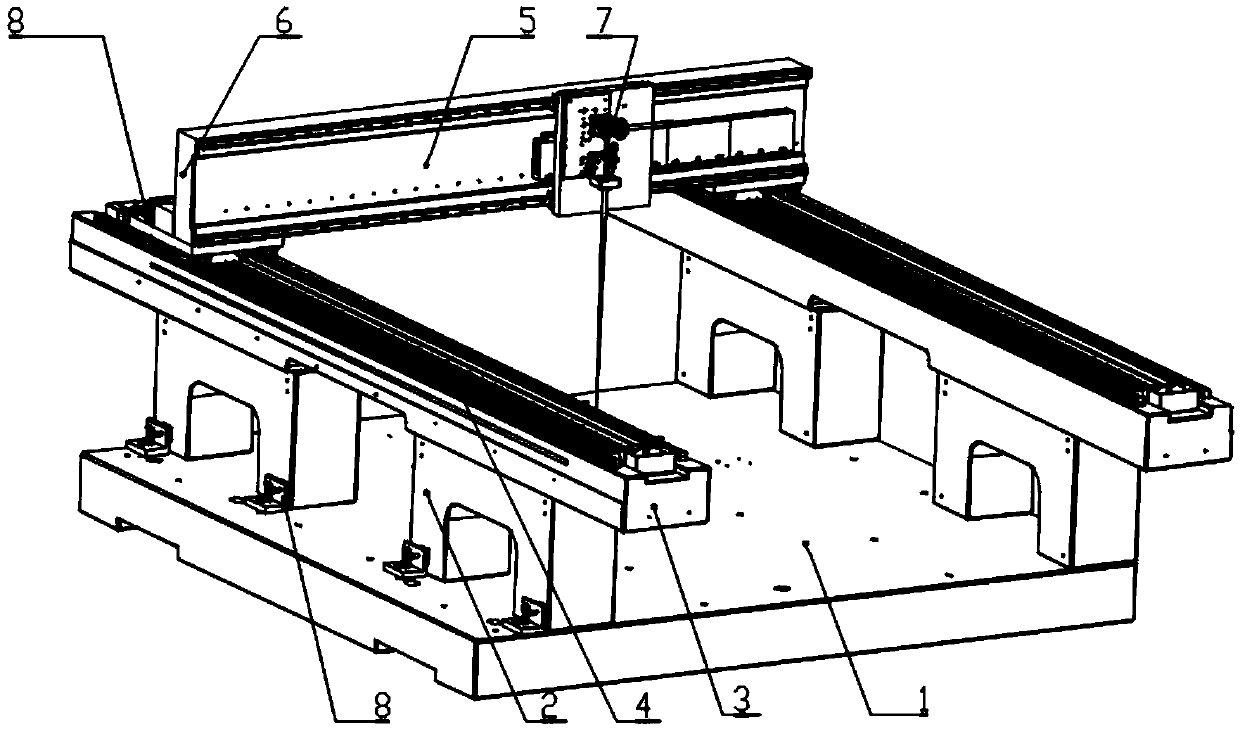

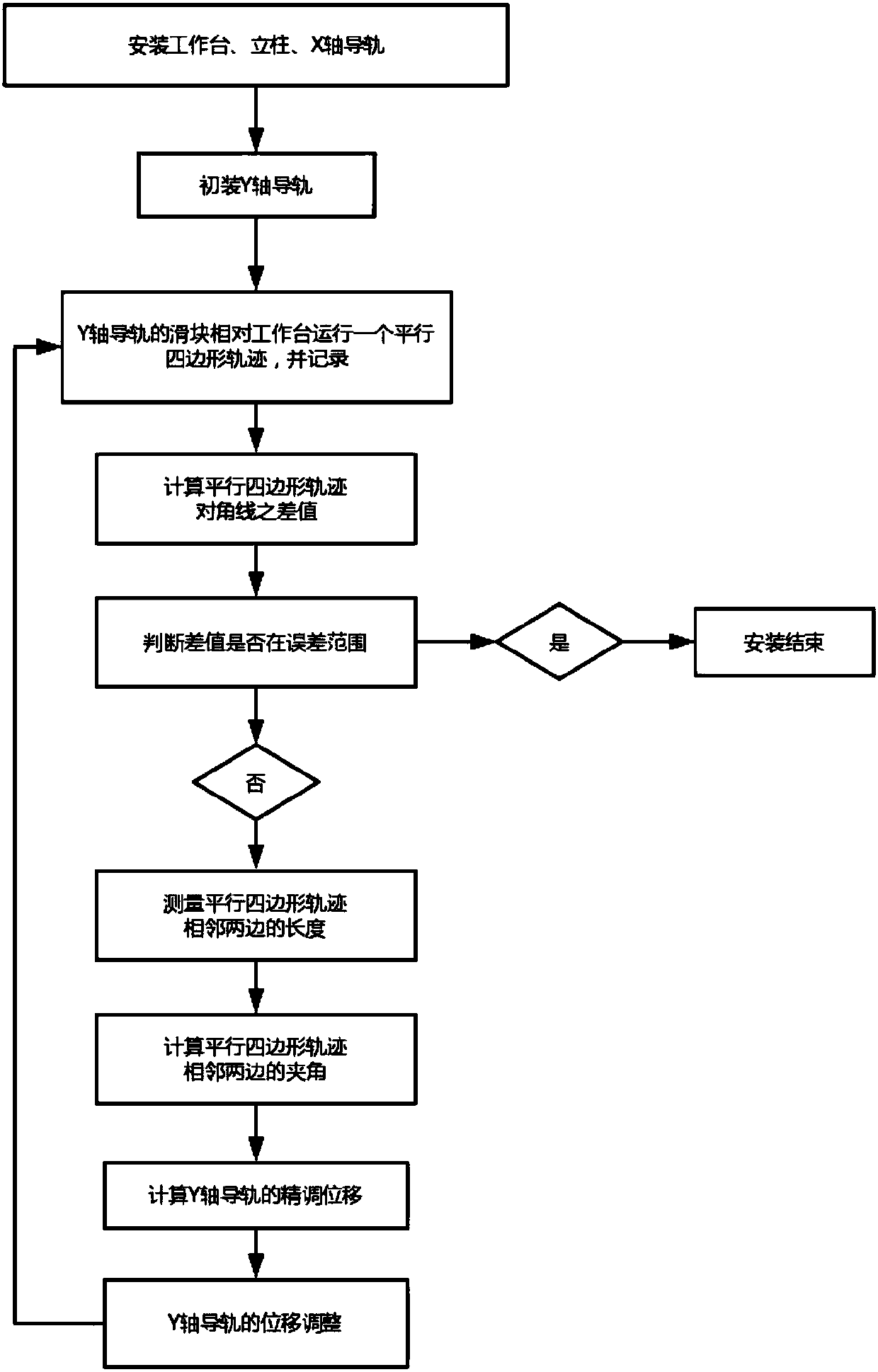

[0045] see figure 1 , this embodiment takes the bridge-type large-scale gantry machine tool as an example to introduce the installation method of its gantry structure. see figure 2 , the method includes the following steps.

[0046] Step 1: Installation of Workbench 1.

[0047] Install the workbench 1 on the ground, or install it on a corresponding machine base as required. The installation of the workbench 1 is carried out by a conventional installation method, and the flatness and levelness of the workbench 1 need to be ensured during installation.

[0048] As a large-scale gantry machine tool for precision machining, especially a large-scale gantry machine tool in the field of laser processing technology, the workbench 1 chooses a granite workbench that meets the national standard of GB / T20248-2006 rock slabs to ensure that it has a grade 0 stipulated by the national standard Or Class 1 flatness tolerance.

[0049]Adjustment of levelness is carried out by conventional...

Embodiment 2

[0105] Embodiment 2 is similar to the method of embodiment 1, but, when carrying out the fine adjustment of perpendicularity, can adopt such as Figure 4 The fine adjustment device 8 shown performs the adjustment.

[0106] The fine adjustment device 8 includes a pull plate. The pull plate is a pull plate with an L-shaped cross section, one end is a fixing portion 81 , and the other end is an adjusting portion 82 . Fix according to the parts that need to be adjusted. For example, when it is necessary to adjust the verticality of the Y-axis guide rail 5 and the X-axis guide rail 4, the fixing part 81 is fixed on the fixed surface of the Y-axis guide rail 5, or the fixing part 81 is fixed on the Y-axis On the fixed surface of the Y-axis beam 6 where the guide rail 5 is located, the adjusting part 82 is fixed on the Y-axis guide rail 5 to be adjusted or the Y-axis beam 6 .

[0107] The adjustment part 82 includes a push rod 83 and a pull rod 84. The push rod 83 is a threaded rod...

Embodiment 3

[0116] This embodiment takes the fixed beam type and the moving beam type large-scale gantry machine tools as examples to illustrate the installation method, which is similar to the second embodiment.

[0117] The difference is that the installation of the X-axis guide rail 4 is completed first, and the parallelism of the X-axis guide rail 4 is adjusted. Then, the workbench 1 is installed on the slider of the X-axis guide rail 4, and the levelness of the workbench 1 is tested. Adjust the levelness of the workbench 1 by plugging the gasket in the fixed part of the slide block between the table 1 and the X-axis guide rail 4. Then complete the installation of the Y-axis guide rail 5 .

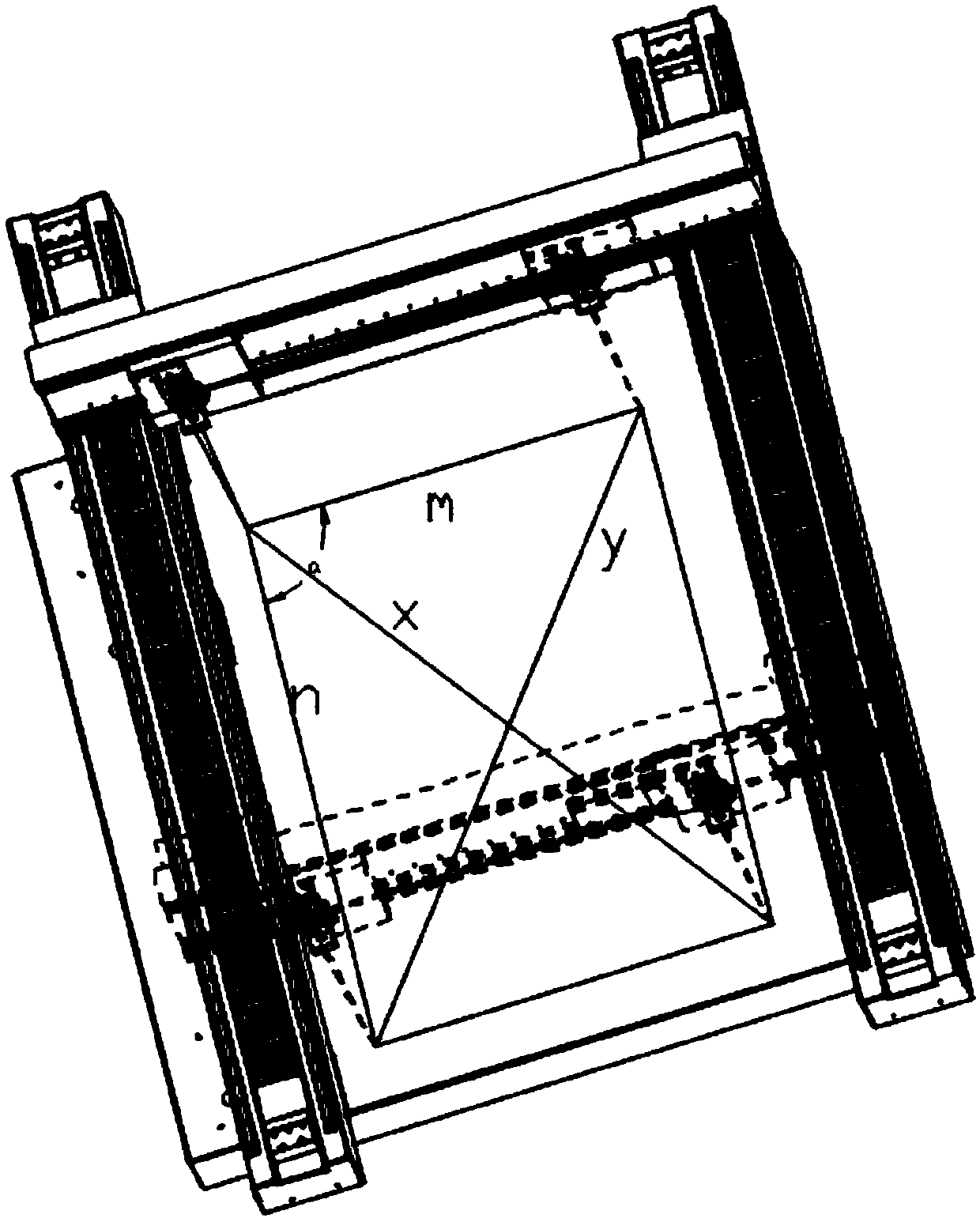

[0118] The difference lies in that when vertically adjusting the Y-axis guide rail 5 and the X-axis guide rail 4, the drawing method is different. Specifically, first move the slider of the Y-axis guide rail 5 to one end of the Y-axis guide rail 5, and the working table 1 Move to one end of the X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com