Spherical small particle size mesoporous composite material and supported catalyst and preparation method thereof

A composite material and small particle size technology, applied in the field of mesoporous materials, can solve the problems of poor thermal stability and hydrothermal stability, low ethylene polymerization activity, affecting catalytic activity, etc., achieve stable mesoporous structure, improve fluidity, Apply handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

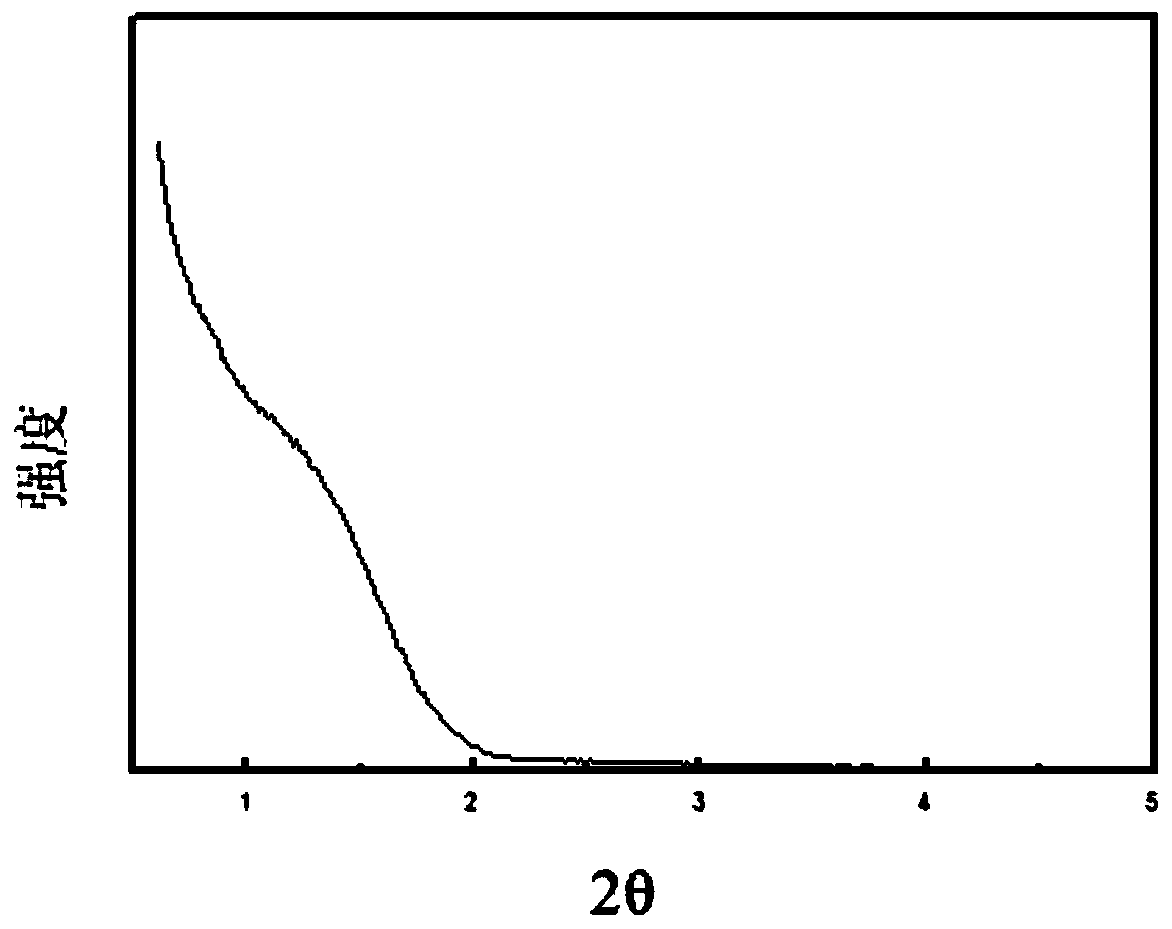

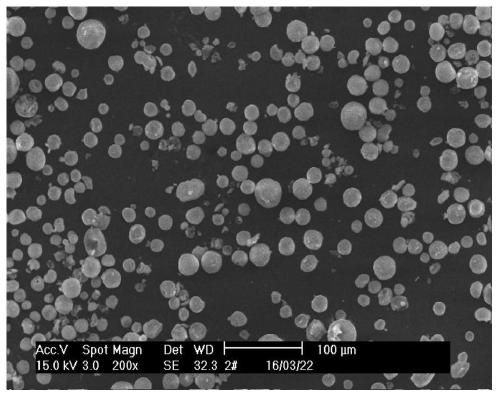

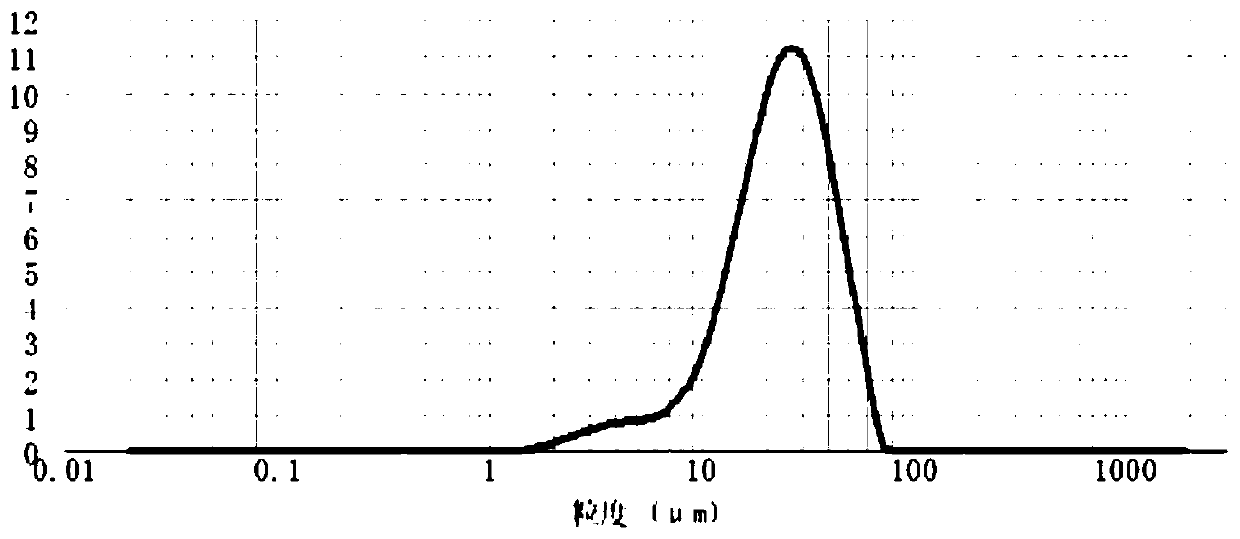

[0028] According to a preferred embodiment of the present invention, the average particle diameter of the spherical small-diameter mesoporous composite material is 22-28 microns, the specific surface area is 250-350 square meters per gram, and the pore volume is 1.0-1.5 milliliters / gram. grams, the pore size is bimodal, and the most probable pore sizes corresponding to the bimodal are 5-10 nanometers and 20-35 nanometers;

[0029] According to a more preferred embodiment of the present invention, the average particle diameter of the spherical small particle mesoporous composite material is 23-27 microns, the specific surface area is 300-340 square meters per gram, and the pore volume is 1.1-1.4 ml / g, the pore size distribution is bimodal, and the most probable pore sizes corresponding to the bimodal are 6-9 nanometers and 25-35 nanometers respectively.

[0030] In the present invention, the average particle diameter of the spherical small particle diameter mesoporous composit...

Embodiment 1

[0087] This example is used to illustrate the spherical small particle size mesoporous composite material and supported catalyst of the present invention and the preparation method thereof.

[0088] (1) Preparation of spherical small particle size mesoporous composites

[0089] With 1.46g (0.0001mol) template F108, 5.24g (0.03mol) of K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 (2N) at 38°C until F108 is completely dissolved;

[0090] Add 4.2g (0.02mol) of tetraethyl orthosilicate to the above solution, stir at 38°C for 15 minutes, and stand at 38°C for 24 hours;

[0091] Then it was transferred to an agate-lined reactor, crystallized at 100°C for 24 hours, then filtered and washed 4 times with deionized water, and then suction filtered to obtain a mesoporous molecular sieve material with a three-dimensional cubic cage-like channel structure. Filter cake A1.

[0092] The water glass with a concentration of 15% by weight and the sulfuric acid s...

Embodiment 2

[0107] This example is used to illustrate the spherical small particle size mesoporous composite material and supported catalyst of the present invention and the preparation method thereof.

[0108] (1) Preparation of spherical small particle size mesoporous composites

[0109] With 1.46g (0.0001mol) template F108, 6.96g (0.04mol) of K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 (2N) at 38°C until F108 is completely dissolved;

[0110] Add 3.1g (0.015mol) of tetraethyl orthosilicate to the above solution, stir at 45°C for 15min, and stand at 45°C for 30 hours;

[0111] Then it was transferred to an agate-lined reactor, crystallized at 120°C for 30 hours, then filtered and washed 4 times with deionized water, and then suction filtered to obtain a mesoporous molecular sieve material with a three-dimensional cubic cage-like channel structure. Filter cake A2.

[0112] A concentration of 20% by weight of water glass and a concentration of 12% by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com