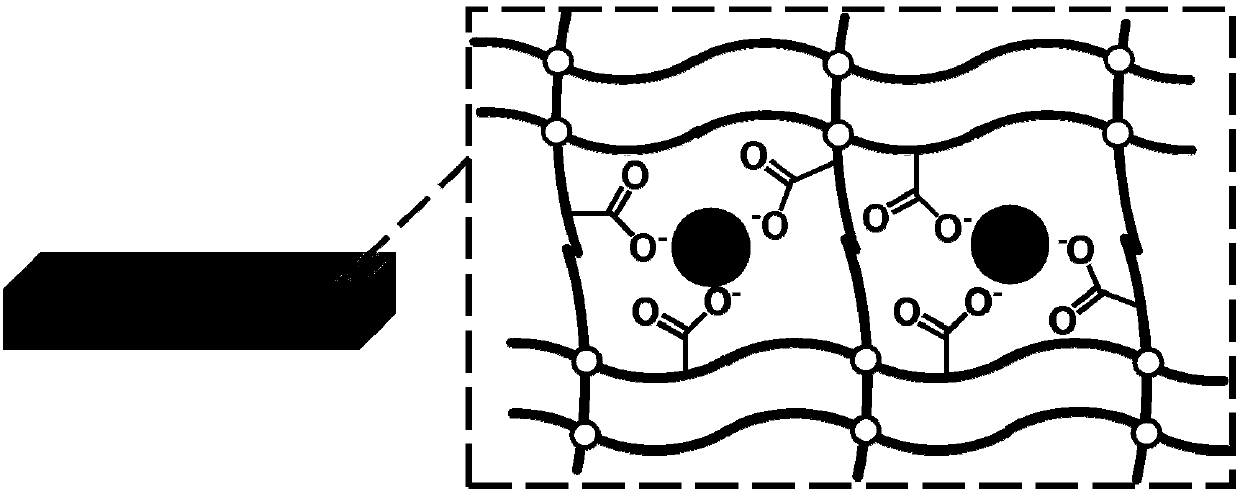

Bilayer hydrogel for promoting interfacial bonding through non-covalent action and preparation method thereof

An interface bonding and hydrogel technology, applied in the field of new bilayer hydrogel and its preparation, can solve the problems of limiting the application prospect of bilayer hydrogel, difficult to control, weak interface bonding, etc., and achieves good application prospect, excellent The effect of interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 6mmol acrylamide, 4mmol acrylic acid, 0.05mmol chemical cross-linking agent N,N'-methylenebisacrylamide, 0.01mmol initiator potassium persulfate in 10ml deionized water at room temperature to obtain a clear prepolymer solution. Add the pre-polymerization solution into the mold and seal it, and react at 60° C. for 5 hours to obtain sheet-shaped hydrogel. Two pieces of hydrogels prepared above were assembled together, and then soaked in FeCl with a concentration of 0.1mol / L 3 ·6H 2 In the O aqueous solution for 8 hours, a tightly fitting double-layer hydrogel is obtained, and the interfacial binding force of the double-layer gel can reach 53kPa.

Embodiment 2

[0020] Dissolve 38 mmol of hydroxyethyl methacrylate, 2 mmol of acrylic acid, 0.8 mmol of chemical crosslinker N,N'-methylenebisacrylamide, and 0.2 mmol of initiator potassium persulfate in 10 ml of deionized water at room temperature to obtain a clear pre- poly liquid. Add the pre-polymerization solution into the mold and seal it, and react at 50° C. for 0.1 hour to obtain sheet-shaped hydrogel. Two pieces of hydrogels prepared above were assembled together, and then soaked in FeCl with a concentration of 0.5mol / L 3 ·6H 2 In the O aqueous solution for 15 hours, a tightly fitting double-layer hydrogel is obtained, and the interfacial binding force of the double-layer gel can reach 39kPa.

Embodiment 3

[0022] Dissolve 28mmol acrylamide, 28mmol hydroxyethyl methacrylate, 14mmol acrylic acid, 0.007mmol chemical crosslinker N,N'-methylenebisacrylamide, 0.07mmol initiator ammonium persulfate in 10ml deionized water at room temperature, A clear prepolymer solution was obtained. Add the pre-polymerization solution into the mold and seal it, and react at 70°C for 12 hours to obtain sheet-shaped hydrogel. Two pieces of hydrogels prepared above were assembled together, and then soaked in FeCl with a concentration of 0.01mol / L 3 ·6H 2 In O aqueous solution for 2 hours, a tightly fitting double-layer hydrogel is obtained, and the interfacial binding force of the double-layer gel can reach 46kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com