Method for lowering pour point depression of crude oil and corresponding crude oil

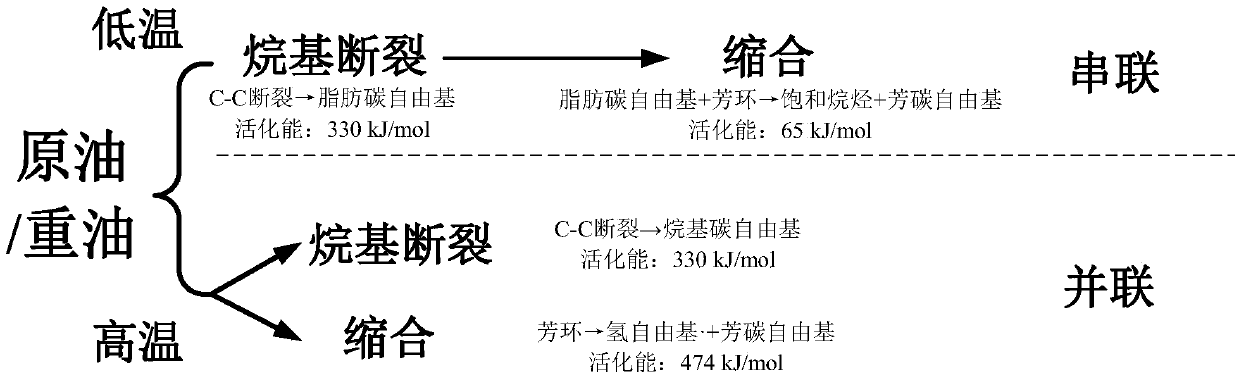

A technology for pour point depressurization and crude oil, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., can solve problems such as kinetic limitations and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The crude oil produced in Daqing, China, with high wax and high freezing point was used as the crude oil sample, and the pour point depressing treatment was carried out.

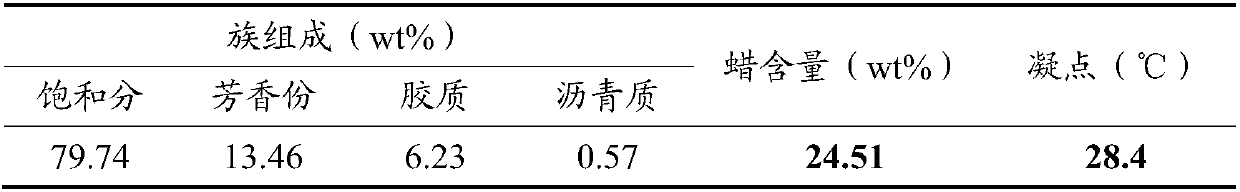

[0064] The basic properties of crude oil are shown in Table 1:

[0065] Table 1 Basic properties of Daqing crude oil

[0066]

[0067] The determination of the freezing point of crude oil and pour point depressant products is carried out according to the standard SY / T 0541-2009, the determination of the group composition is carried out according to the standard SY / T5119-2016, and the measurement of the wax content is carried out according to the standard SY / T 7550-2012.

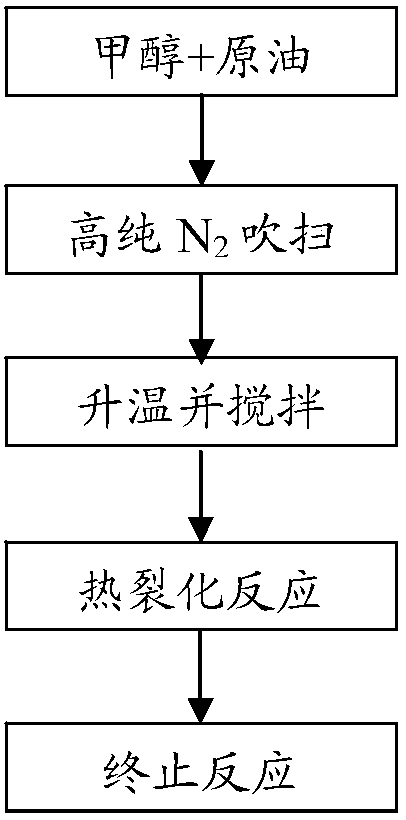

[0068] The specific implementation steps are:

[0069] Add methanol and crude oil respectively in the reactor;

[0070] The amount of methanol added is 25% of the volume of the reactor, and the density of methanol under reaction conditions is controlled to be 0.25g / cm 3 , the mass ratio of methanol and crude oil at normal tempe...

Embodiment 2

[0082] Similarly, high-wax and high-condensation crude oil produced in Daqing, China was used as a crude oil sample for depressing treatment.

[0083] The basic properties of crude oil are shown in Table 1.

[0084] The determination of the freezing point, group composition and wax content of crude oil and pour point depressant products is based on the same standard as example 1.

[0085] The specific implementation steps are:

[0086] Add methanol and crude oil respectively in the reactor;

[0087] The amount of methanol added is 30% of the volume of the reactor, and the density of methanol under reaction conditions is controlled to be 0.30g / cm 3 , the mass ratio of methanol and crude oil at normal temperature is 4:1;

[0088] The reaction kettle was purged with high-purity nitrogen to replace the air and sealed, then the temperature was raised to 400℃ with a gradient of 15°C / min and the timing was started. After the set reaction time was reached, the heating was stopped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com