Perforating gun barrel material and preparation method thereof

A technology for perforating gun barrels and steel pipes, which is applied in the fields of seamless steel pipe materials and their preparation, gun barrel steel pipe materials and their preparation fields, can solve the problems of high cost, large quenching stress, high production difficulty and the like, and achieve reduced sensitivity , The effect of reducing internal stress and eliminating quenching oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

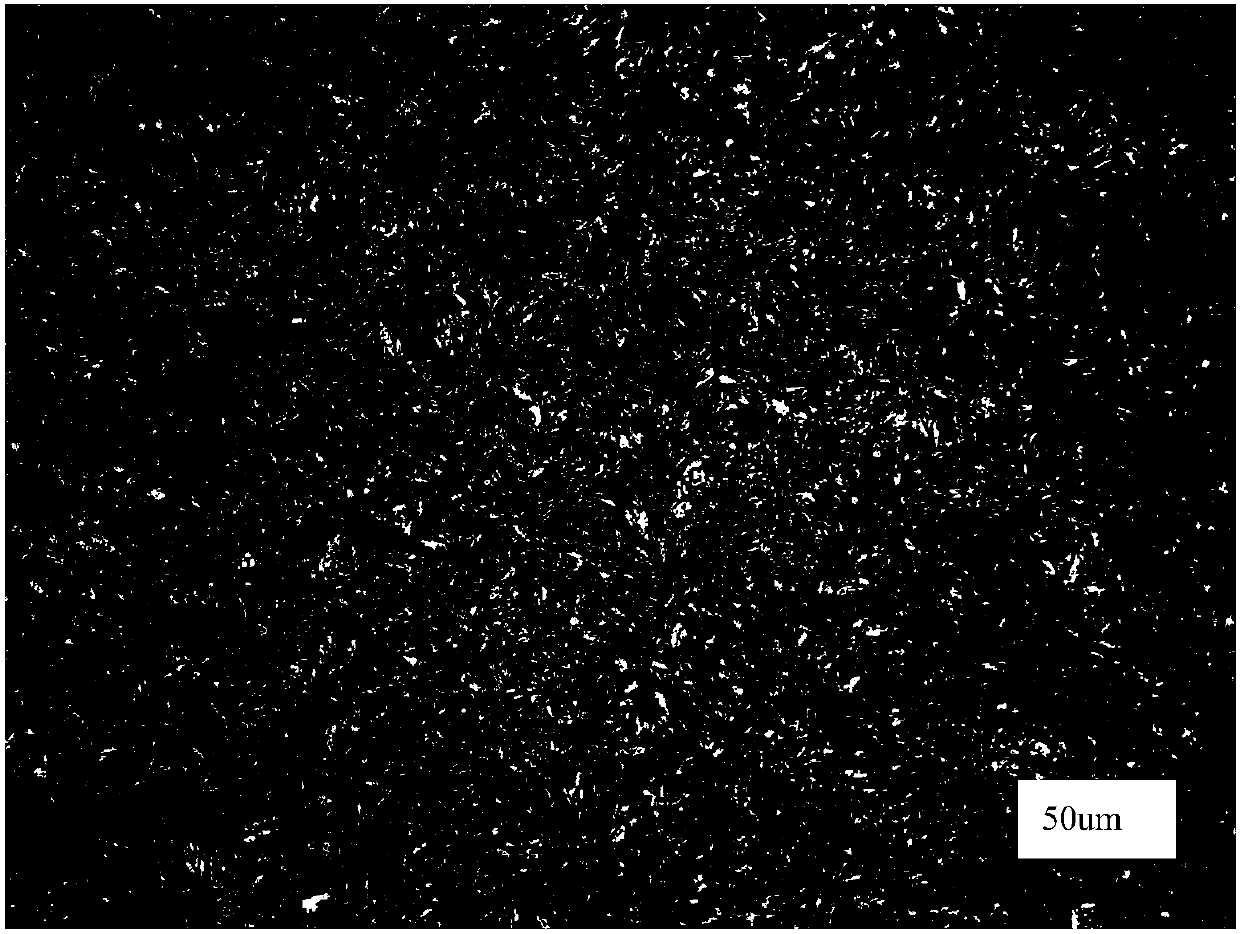

Image

Examples

Embodiment 1~ Embodiment 6

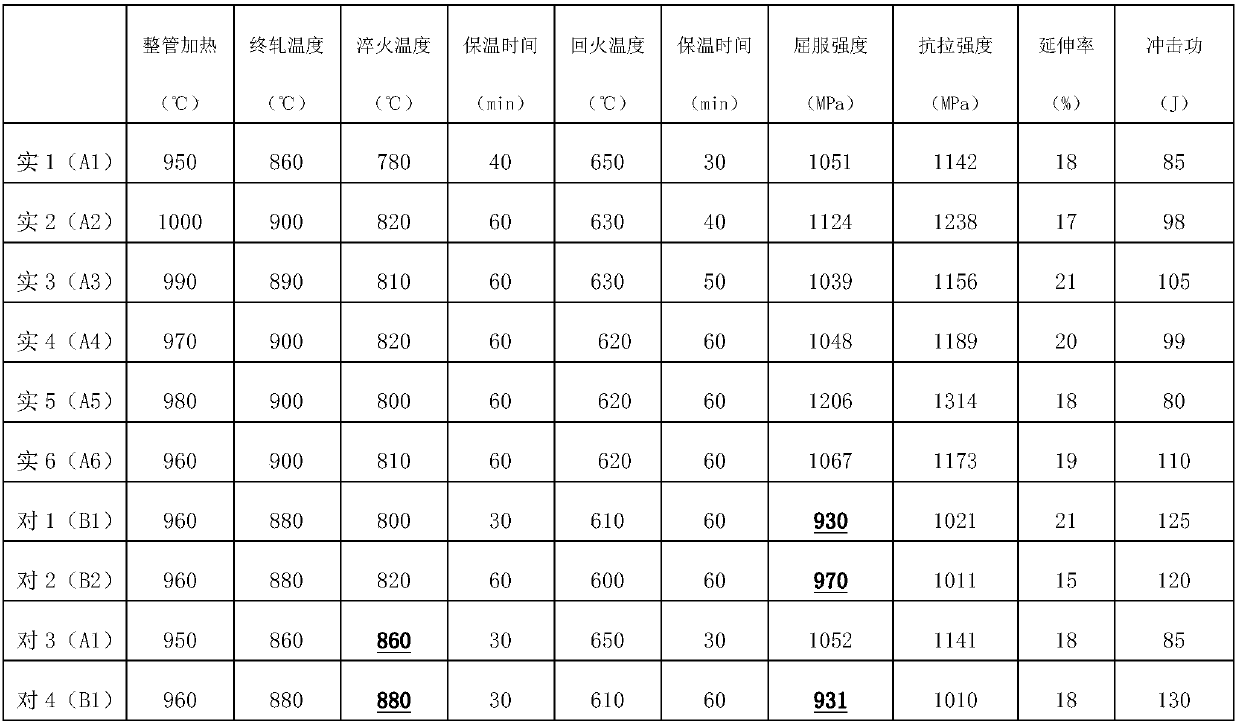

[0039] The steel pipe material of the perforating gun described in Embodiment 1-6 of the present invention is obtained by the following method, wherein the mass percentage ratio of the chemical elements of the steel pipe is shown in Table 1, A1-A6 corresponds to Embodiment 1-6, B1-B2 of the present invention Corresponding to Comparative Example 1-2; Comparative Example 3-4 corresponds to the situation of B1 and B2 under complete quenching conditions.

[0040] Examples 1 to 6 prepared a perforating gun barrel material, and the mass percentage ratio of the chemical elements of the material components is:

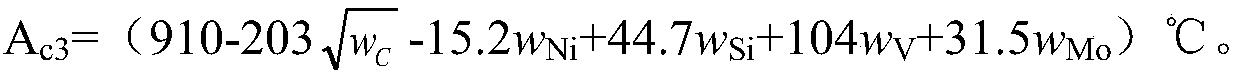

[0041] C: 0.25-0.35%; Si: 0.15-0.35%; Mn: 0.4-0.8%; Cr: 0.8-1.2%; Mo: 0.15-0.45%; Al: 0.005-0.05%; Cu: ≤0.15%; Ni: ≤0.2%; V: ≤0.06%; Nb: ≤0.05%; Ti: ≤0.03%; Ca: 0.001-0.0065%; P1, and satisfy the quality relationship formula of 0.6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com