Sanitary deceleration transmission mechanism special for stirring

A deceleration transmission, sanitary technology, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of long output shaft, easy aging of seals, easy distortion of hollow shaft, etc., to reduce volume, reduce The effect of wear and length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

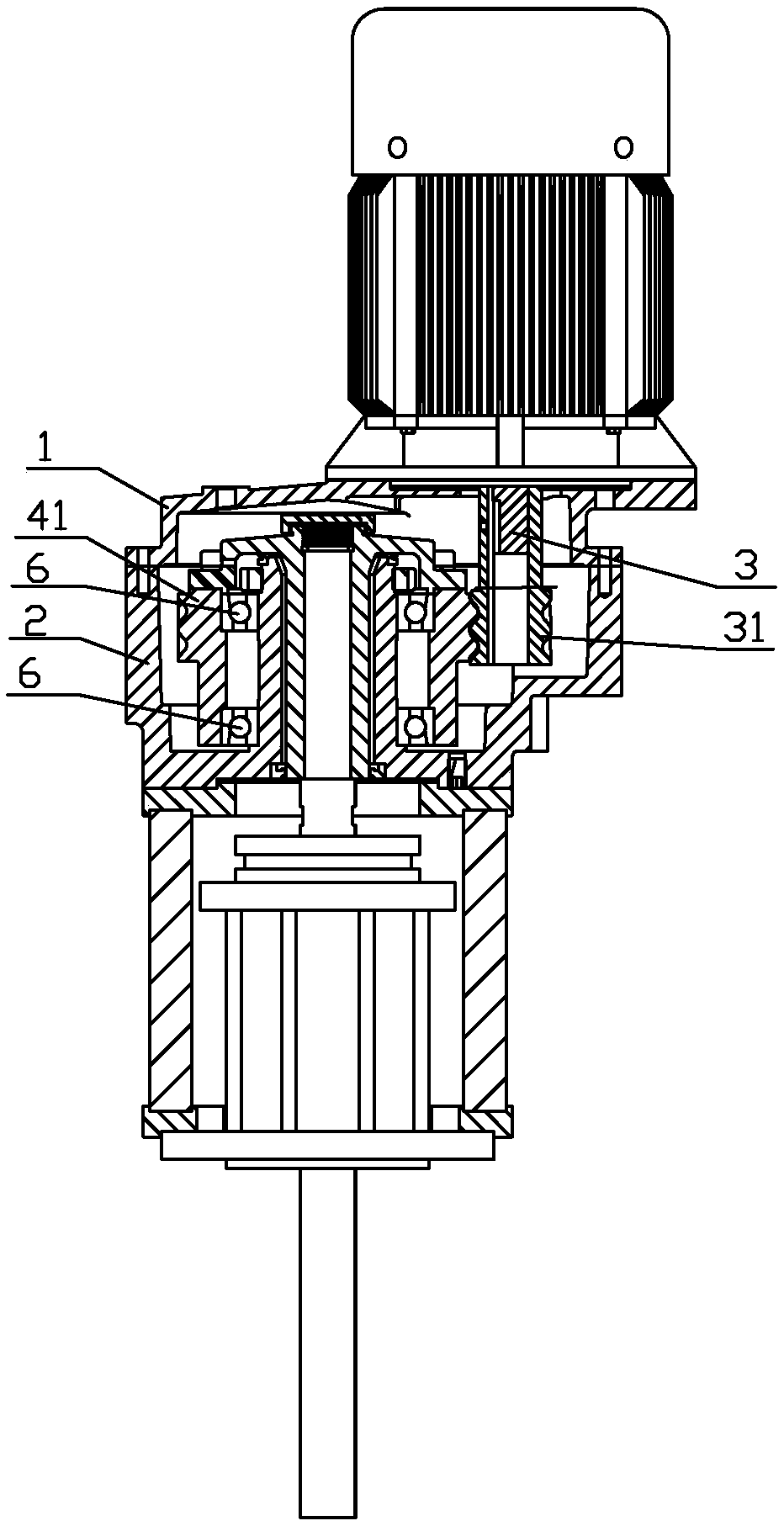

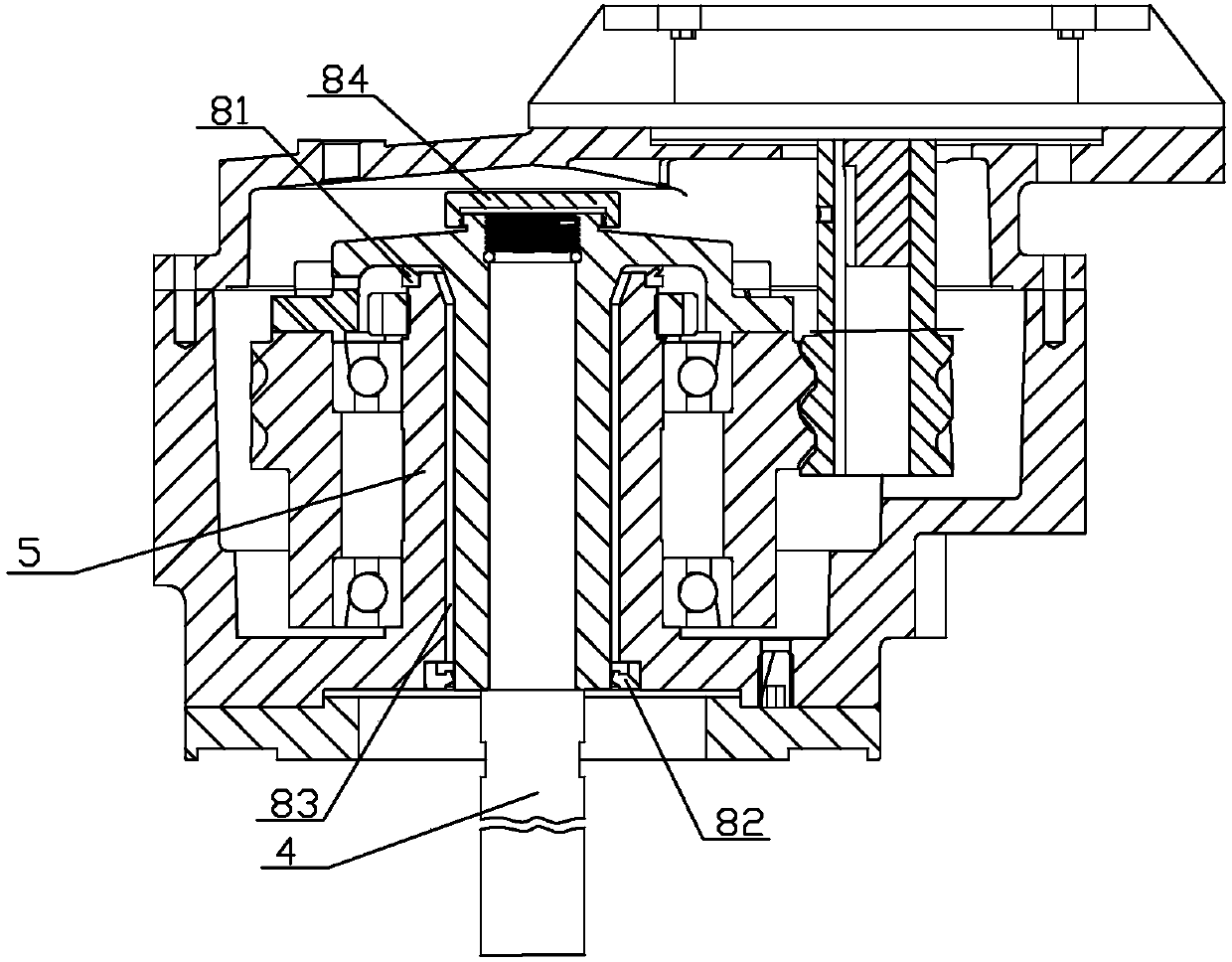

[0021] like figure 1 , figure 2 and image 3 As shown, a special deceleration transmission mechanism for hygienic stirring disclosed by the present invention includes a casing composed of an upper box 1 and a lower box 2, the upper box 1 and the lower box 2 are split structures, and the upper box 1 has a structure for fixing the driving motor, the driving motor is fixed on the upper box 1, the rotating shaft of the driving motor is connected with the input shaft 3 in the reduction transmission device through a structure such as a coupling, and the driving gear 31 is installed on the input shaft 3.

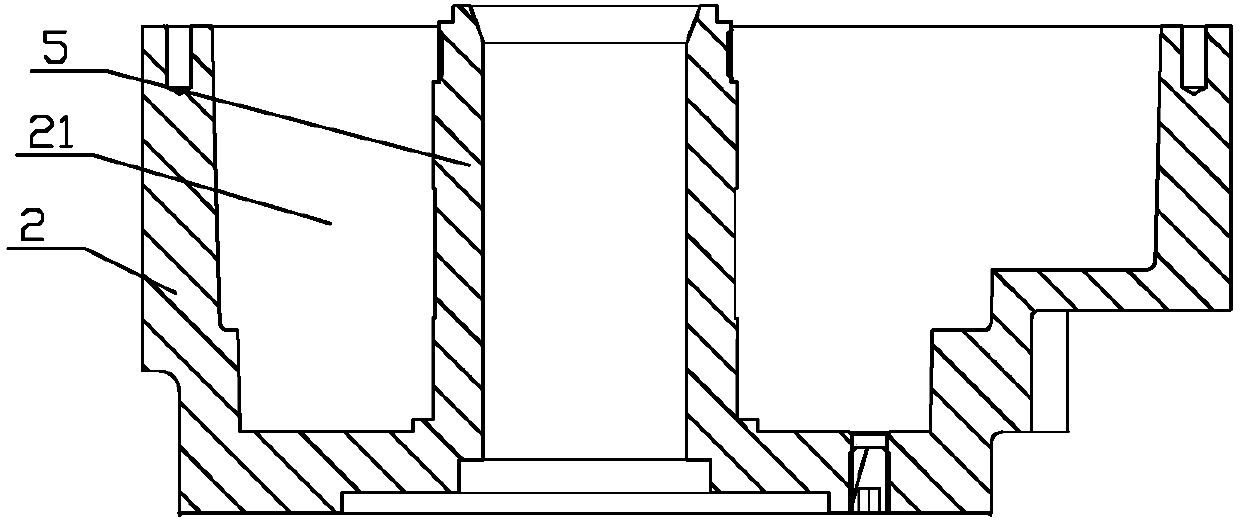

[0022] The lower casing 2 has a dry well casing 5 integrally cast with the sleeve structure, an oil storage tank 21 is formed between the dry well casing 5 and the lower casing 2, and the driving gear 31 and the driven gear 41 are placed in the oil storage tank 21 Inside, a bearing 6 is installed on the upper and lower ends of the outer wall of the dry well casing 5, and the dri...

Embodiment 2

[0029] A mixer includes a drive motor, a reduction transmission mechanism and a stirring wheel connected to the output shaft of the reduction transmission mechanism. The reduction transmission mechanism of the mixer adopts the reduction transmission mechanism of the integrated structure of the dry well casing and the chassis disclosed in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com