Low-temperature box for middle-size and large-size test pieces

A low-temperature box, large-scale technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of high risk of frostbite, poor economy, and large loss of cooling capacity, and achieve test safety. And the effect of high normative requirements, good use economy and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present invention will be further described in detail by taking a low-temperature box for medium and large-sized specimens with a cooling range of 0 to -196°C to meet the drop weight test specimens (length 360 or 130 mm, width 90 or 50 mm, thickness ≤ 50 mm) as an example.

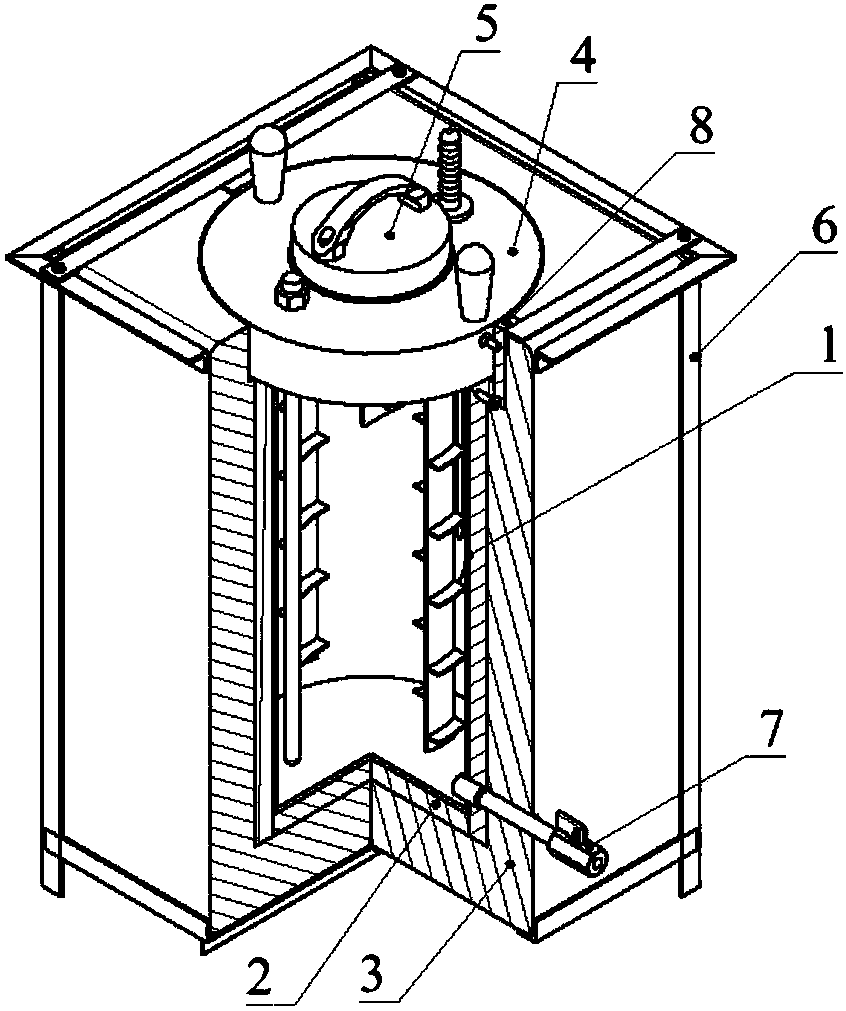

[0047] refer to figure 1 . The low-temperature box for large-sized test pieces in the present invention includes: cold insulation cylinder body 1, cold insulation layer 2, insulation box 3, cold insulation cylinder cover assembly 4, specimen hanger assembly 5, outer frame 6, liquid discharge pipe valve assembly 7, cylinder Body connection block 8.

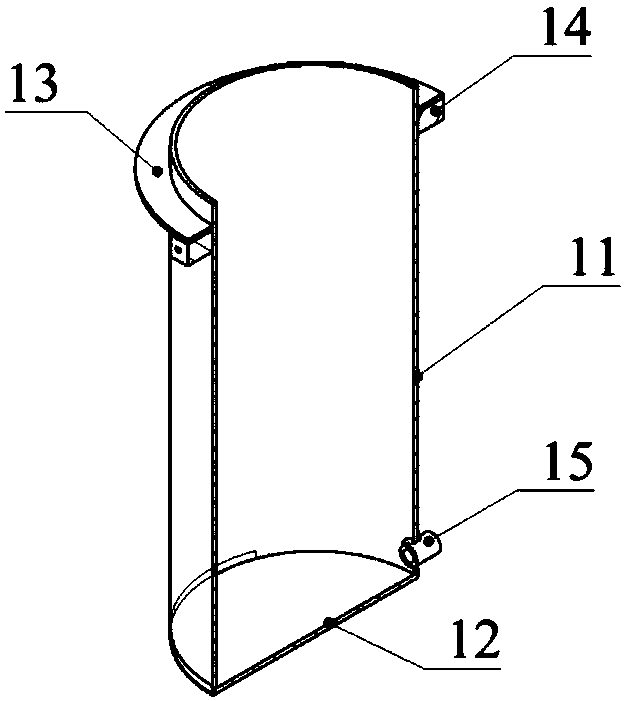

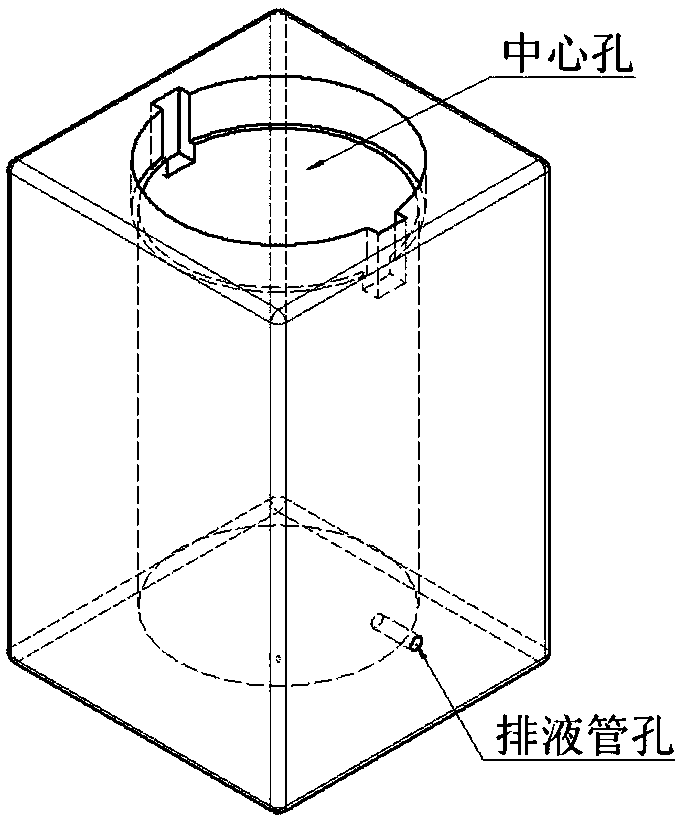

[0048] refer to figure 2 . The cold insulation cylinder 1 is a vertical cylindrical welded structure, including: φ219×3×450mm low-temperature austenitic stainless steel pipe section 11, low-temperature austenitic stainless steel cylinder bottom plate 12, stainless steel retaining ring 13, stainless steel cylinder fixing ear 14 and a low-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com