Continuous halving double-antipodal-type magnetic system permanent magnet high-gradient strong magnetic separation device

A counterpolar, high-gradient technology, applied in high-gradient magnetic separators, magnetic separation, solid separation, etc., can solve the problems of low magnetic field strength, non-continuous operation, and narrow separation space, so as to achieve uniform magnetic field strength and prevent Flux leakage phenomenon, the effect of improving the throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

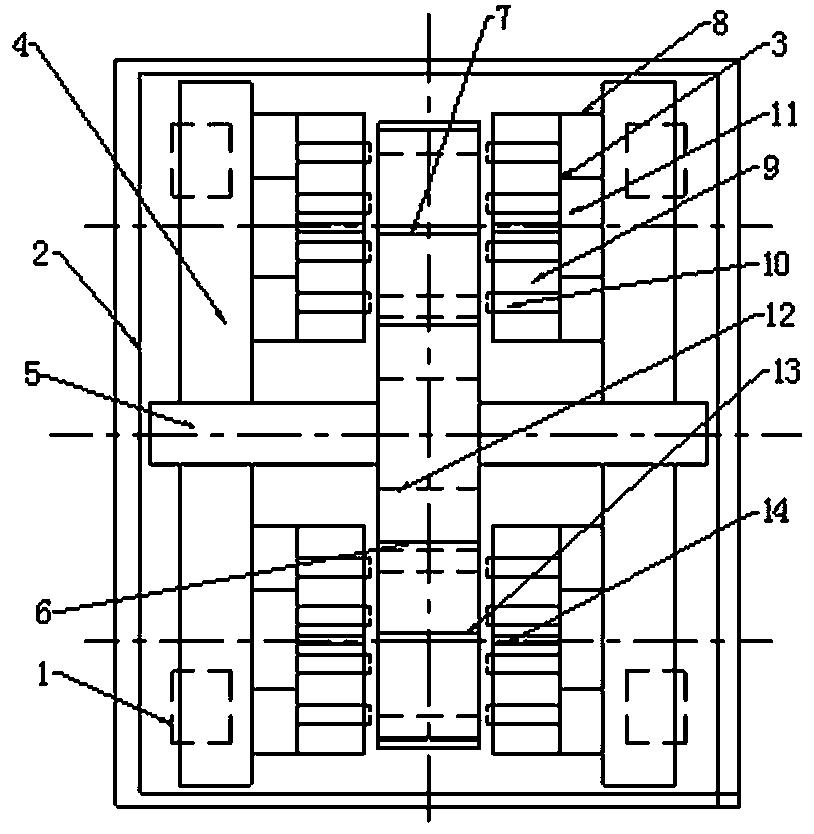

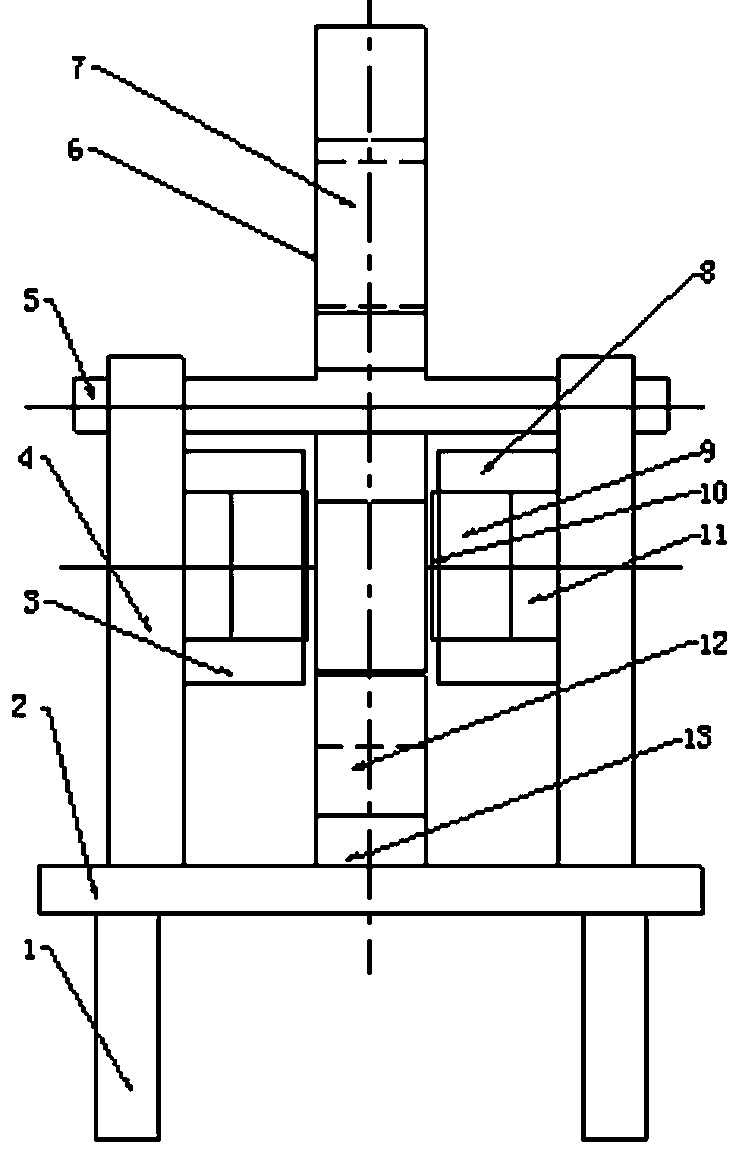

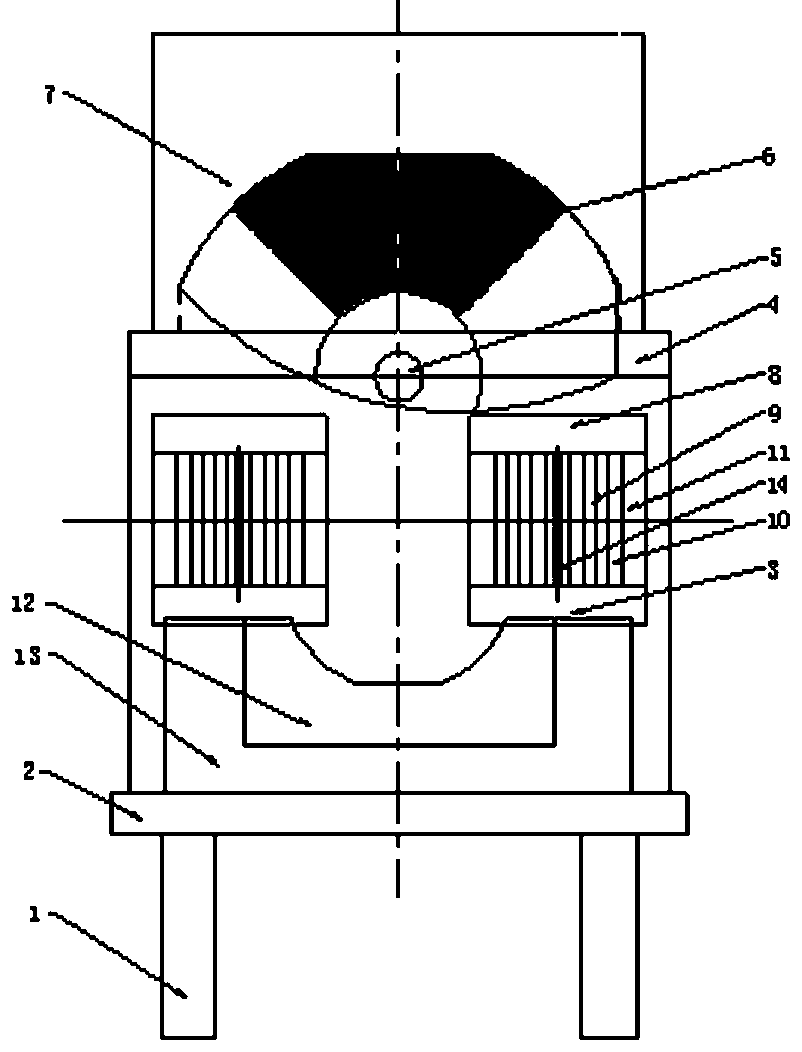

[0033] like figure 1 , 2, 3, the magnetic system device of the present invention is mainly composed of a frame 1, a support platform 2, a square permanent magnet 3 for extruding the bottom, a magnetic system yoke 4, a rotating shaft 5, a magnetic gathering medium cylinder 6, and a feeding chute 7 1. Square permanent magnet for upper extrusion 8. One of several square permanent magnets for middle extrusion 9. One of several square soft iron magnetic poles for middle extrusion 10. Square permanent magnet for extrusion close to the yoke 11. Magnetic material The collection tank 12, the non-magnetic material collection tank 13, the square permanent magnet for extrusion in the middle, and the square soft iron magnetic pole group 14 for extrusion in the middle, etc.;

[0034] To be specific: the whole machine of the present invention adopts a center-divided double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com