Coupler serpentine spring and production technology thereof

A serpentine spring and production process technology, applied in the field of serpentine spring and its production process, can solve problems affecting the service performance of serpentine spring, corrosion of serpentine spring, etc., and achieve the effect of reducing the possibility of electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

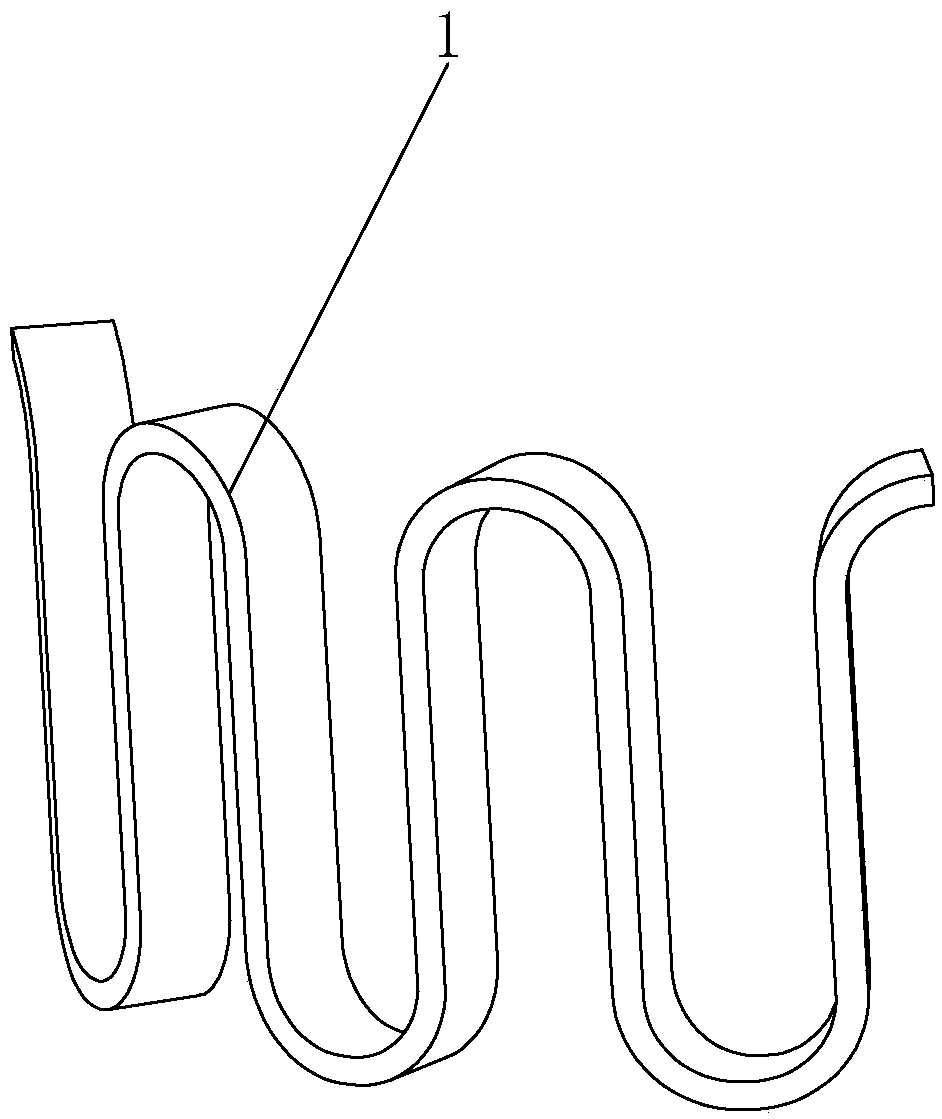

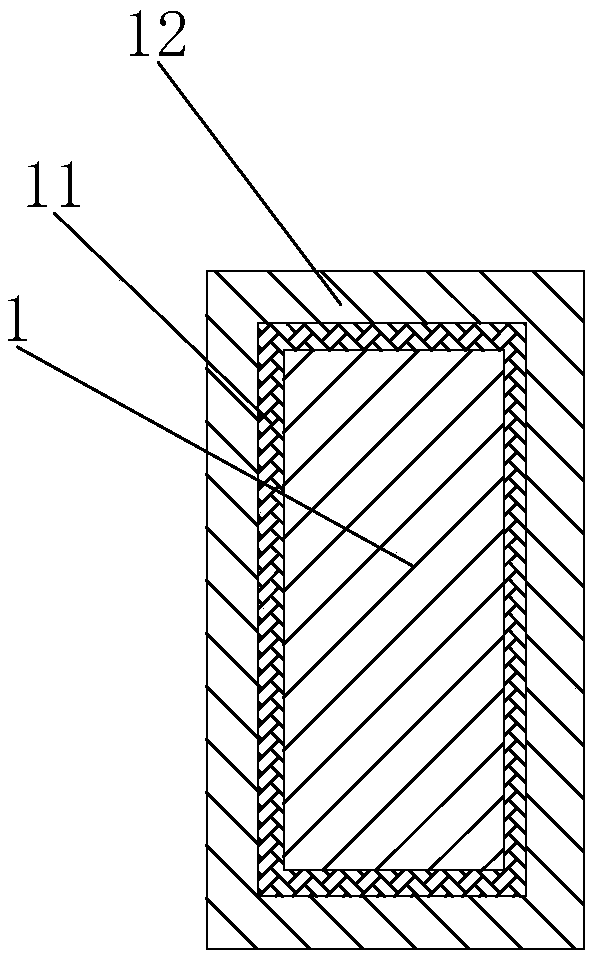

[0046] Example 1: A serpentine spring for coupling, refer to figure 1 This kind of serpentine spring for couplings includes a spring body 1 bent in a serpentine shape; the spring body 1 is coated with a fluorocarbon coating layer 11 (refer to figure 2 ), where fluorocarbon coating refers to coatings with fluororesin as the main film-forming substance; also known as fluorocarbon paint, fluorocoating, fluororesin coating, etc. Among various coatings, fluororesin coatings have particularly excellent properties due to the high electronegativity of the introduced fluorine element and strong carbon-fluorine bond energy. Weather resistance, heat resistance, low temperature resistance, chemical resistance, and unique non-stick and low friction.

[0047] Reference figure 2 , Located at the end of the spring body 1 and on the side of the fluorocarbon coating layer 11 away from the spring body 1 is coated with a wear-resistant ceramic coating layer 12, wherein the wear-resistant ceramic co...

Embodiment 2

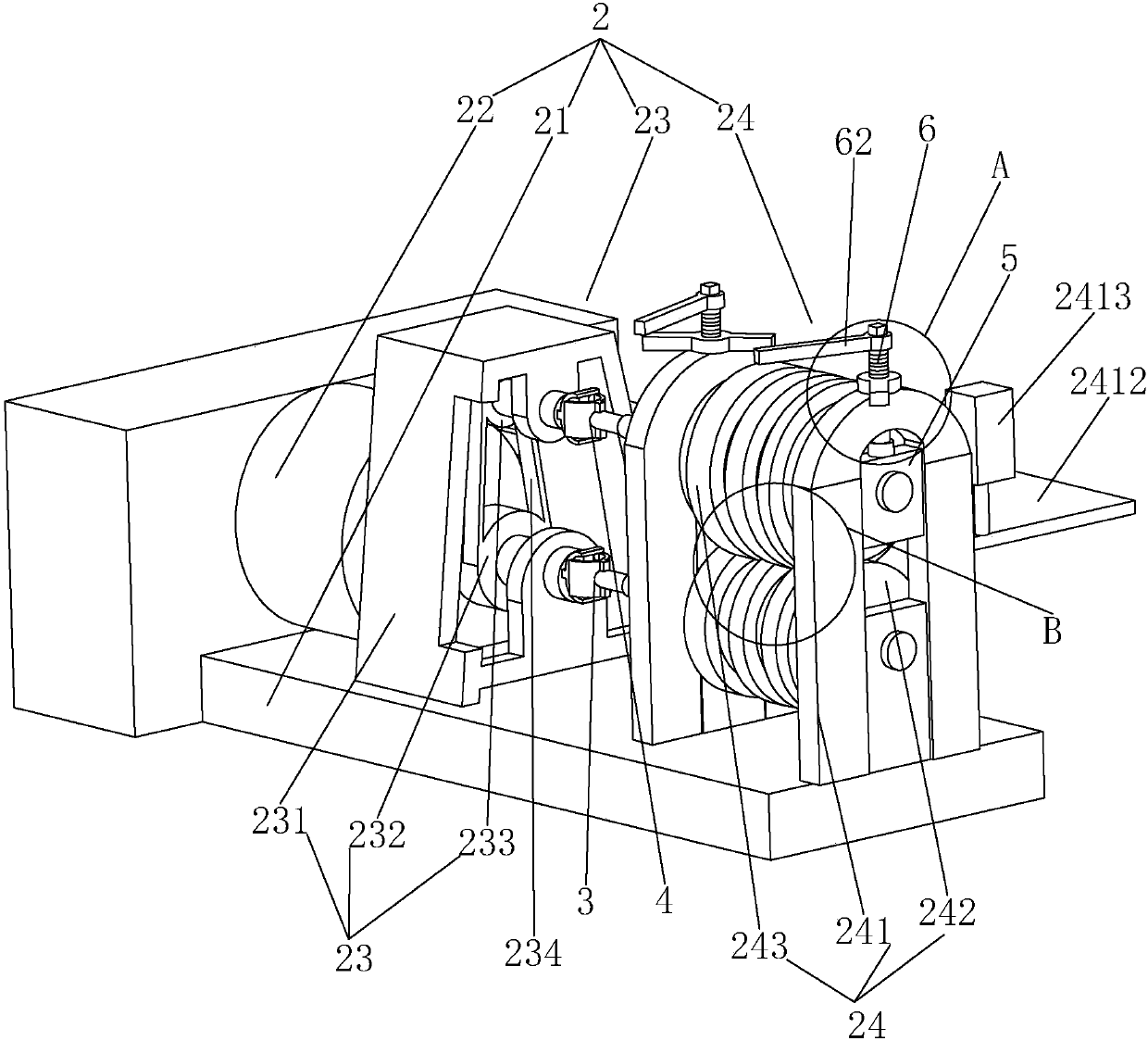

[0048] Embodiment 2: A production process of a serpentine spring used in a coupling. The production process of the serpentine spring used in a coupling includes the following steps: Step 1: Use a first resistance furnace to treat flat steel strips Heat treatment; Step 2: Use flattening machine 2 (refer to image 3 1) Flatten the flat steel strip; Step 3: Use a tube drawing machine to straighten the flat steel strip; Step 4: Use a spring coiling machine to bend the flat steel strip after straightening; Step 5: Use the second resistance furnace to heat the bent blank; Step 6: Use a shot blasting machine for surface treatment; Step 7: Coat the fluorocarbon coating layer 11 on the spring body 1 (refer to figure 2 ).

[0049] Reference image 3 This type of flattening machine 2 includes a frame 21 placed on the ground, a geared motor 22, a transmission part 23, and a flattening part 24; the geared motor 22 is fixed on the frame 21 by bolts, and the transmission part 23 and the geared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com