Method for preparing cement admixture, cement admixture and cement composition

A cement admixture and cement technology, which is applied in the field of solid waste resource utilization, can solve the problems such as the lack of attention and utilization of microbeads in coal gasification fine slag, and achieve the improvement of cement product performance, good fluidity and good separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 1000g of coal gasification fine slag (wherein the solid content is about 55%), and prepare a coal gasification fine slag slurry with a solid content of 10wt%, and use a high-speed dispersion mixer (Guangdong Foshan Yifu Machinery Co., Ltd.) to stir at room temperature. The stirring time is 1800r / min, and the stirring time is 20min; the slurry is introduced into a cyclone separator for separation, and the obtained lower slurry is a silicon-rich slurry, and the carbon content in the solid phase is 8.5wt% after testing;

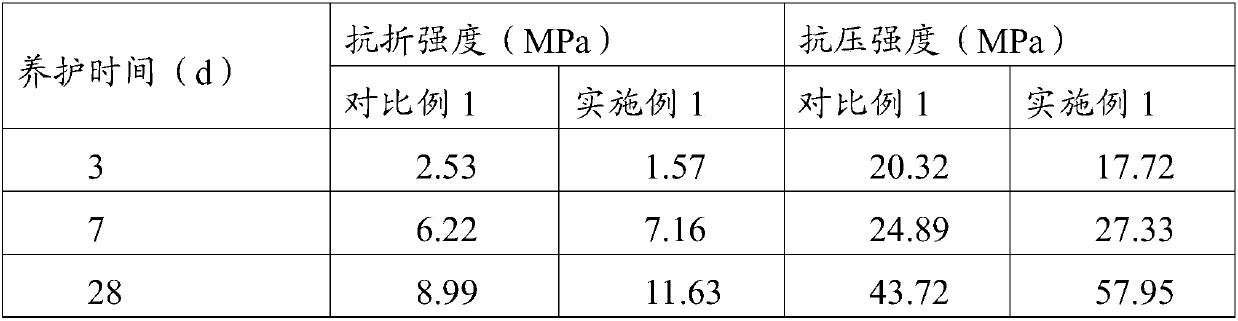

[0029] The separated slurry was subjected to solid-liquid separation, dried at 120°C, and calcined at 600°C for 2 hours to activate carbon removal; take 360g of No. 425 Portland cement (from Yatai Cement Co., Ltd.), 1200g of sand, and 40g of gas after carbon removal. Thin slag microbeads, add 200g of water to reconcile and stir to obtain a mixture; test its fluidity to be 174.5mm; its 3-day, 7-day and 28-day strength test results are shown in Table 1....

Embodiment 2

[0037] Take 1000g of coal gasification fine slag (wherein the solid content is about 55%), and prepare a coal gasification fine slag slurry with a solid content of 20wt%, and use a high-speed dispersion mixer (Guangdong Foshan Yifu Machinery Co., Ltd.) to stir at room temperature. The stirring time is 1800r / min, and the stirring time is 30min; the slurry is introduced into the cyclone separator for separation, and the obtained lower slurry is the silicon-rich slurry, and the carbon content in the solid phase is 6wt% after testing;

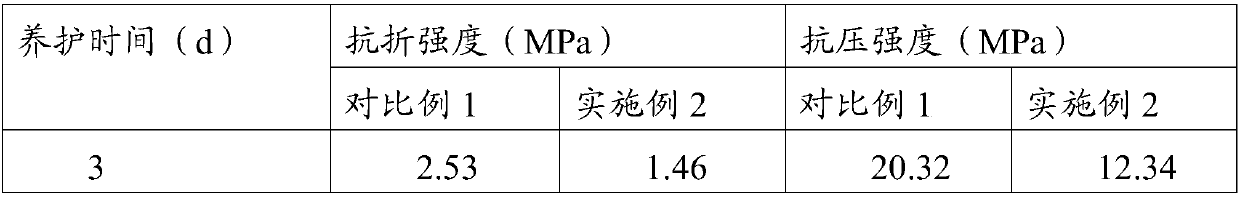

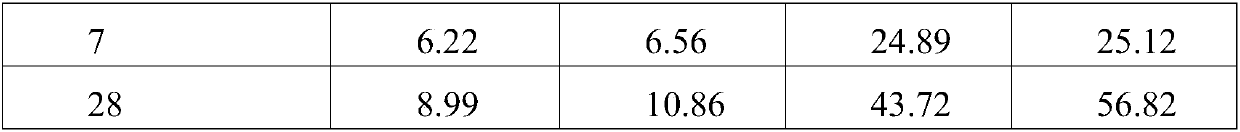

[0038] The separated slurry is subjected to solid-liquid separation, dried at 120°C, and calcined at 650°C for 2 hours to activate carbon removal; take 340g of No. 425 Portland cement, 1200g of sand, 60g of gasified fine slag beads after carbon removal, and add 200g of water to blend Stir to obtain a mixture; test its fluidity to be 170.5mm, which is significantly higher than that of Comparative Example 1; its 3-day, 7-day and 28-day strength test r...

Embodiment 3

[0044] Take 1000g of coal gasification fine slag (wherein the solid content is about 55%), and prepare a coal gasification fine slag slurry with a solid content of 30wt%, and use a high-speed dispersion mixer (Guangdong Foshan Yifu Machinery Co., Ltd.) to stir at room temperature, and the stirring speed The stirring time is 1600r / min, and the stirring time is 40min; the slurry is introduced into a cyclone separator for separation, and the obtained lower slurry is the silicon-rich slurry, and the carbon content in the solid phase is 6.5wt% after testing;

[0045] The separated slurry is subjected to solid-liquid separation, dried at 120°C, and calcined at 700°C for 1.5h to activate carbon removal; take 320g of No. 425 Portland cement, 1200g of sand, and 80g of gasified fine slag beads after carbon removal, and add 200g of water Reconcile and stir to obtain a mixture; the fluidity of the test is 165.0mm, which is obviously higher than that of Comparative Example 1; the strength t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com