Acid texturing additive special for DWS (Diamond Wire Saw) polycrystalline silicon chip

A technology of diamond wire cutting and polysilicon wafers, which is applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of uneven distribution of surface defects, uniform corrosion of texturing process, etc., and achieve good practical application value , easy to implement, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 (reference group)

[0021] This embodiment provides a reference example, which is a conventional texturing process without additives:

[0022] Take the following steps;

[0023] 1) Prepare the acid velvet solution, under stirring, 2L of hydrofluoric acid with a concentration of 49%, 6L of nitric acid with a concentration of 65-68% and 3L of deionized water are mixed evenly;

[0024] 2) Texturing: immerse the diamond wire-cut polysilicon wafer in the above acidic texturing solution for texturing, the texturing temperature is 8-10°C, and the texturing time is 25s.

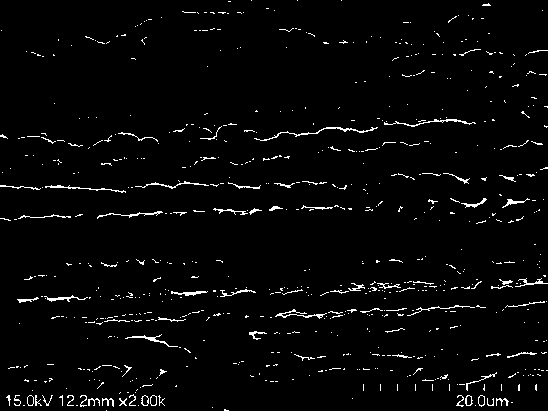

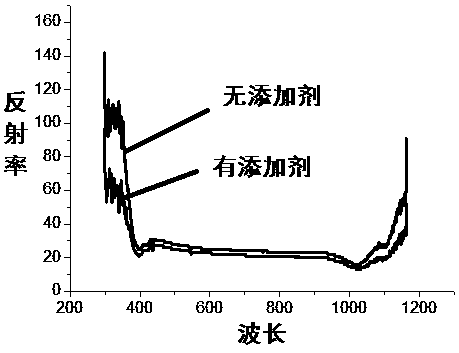

[0025] 3) The surface reflectance of the diamond wire-cut polysilicon wafer after texturing is 40%. figure 1 The scanning electron microscope picture of the surface of the diamond wire-cut polysilicon wafer obtained by the conventional process is given. In the picture, the textured surface is uneven in size and uneven in distribution.

Embodiment 2

[0026] Embodiment 2 (additive group is arranged)

[0027] This embodiment adopts the following steps:

[0028] a) Preparation of additives: under stirring, 1.0g xanthan gum, 1.0g tannic acid and 0.2g silicon-based surfactants are dissolved in 97.8 g deionized water (that is: in the prepared additives, the The weight content of water-soluble xanthan gum is 1%, the weight content of the tannic acid is 1%, and the weight content of silicon-based surfactant is 0.2%)

[0029] b) Preparation of acidic texturing solution: under stirring, mix 2 L of hydrofluoric acid with a concentration of 49%, 6 L of nitric acid with a concentration of 65-68% and 3 L of deionized water, and then add 110 ml of the above-mentioned Additives, stir well

[0030] c) Texturing: immerse the diamond wire-cut polysilicon wafer in the above acid texturing solution for texturing, the texturing temperature is 8-10°C, and the texturing time is 45s.

[0031] d) The surface reflectance of the diamond wire-cut...

Embodiment 3

[0032] Embodiment 3 (additive group is arranged)

[0033] This embodiment adopts the following steps:

[0034] a) Preparation of additives: under stirring, 1.0g xanthan gum, 1.0g tannic acid and 0.2g silicon-based surfactants are dissolved in 97.8 g deionized water (that is: in the prepared additives, the The weight content of water-soluble xanthan gum is 1%, the weight content of the tannic acid is 1%, and the weight content of silicon-based surfactant is 0.2%)

[0035] b) Preparation of acidic texturing solution: under stirring, mix 2 L of hydrofluoric acid with a concentration of 49%, 6 L of nitric acid with a concentration of 65-68% and 3 L of deionized water, and then add 165 ml of the above-mentioned additives, stir well

[0036] c) Texturing: immerse the diamond wire-cut polysilicon wafer in the above acid texturing solution for texturing, the texturing temperature is 8-10°C, and the texturing time is 70s.

[0037] d) The surface reflectance of the diamond wire cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com