Lubricating oil radiator installed in front of turbofan of aircraft engine

An aircraft engine and radiator technology, applied in the cooling of the engine, engine components, and cooling of the turbine/propulsion device, etc., can solve the problems of insufficient heat dissipation capacity of the radiator, induced air turbulence, and reduced space utilization. The effect of simple maintenance, energy saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention is specifically described below in conjunction with accompanying drawing and embodiment:

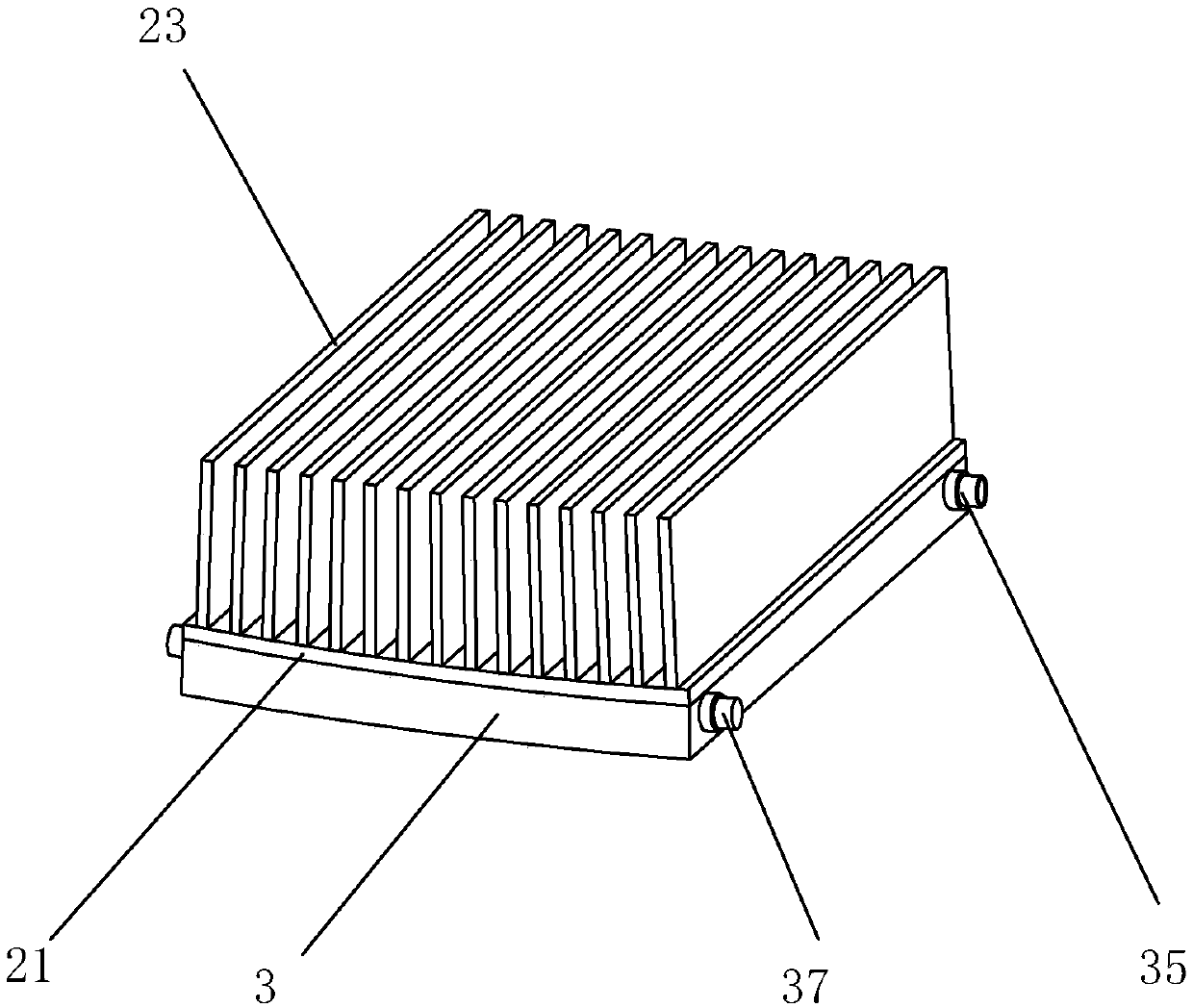

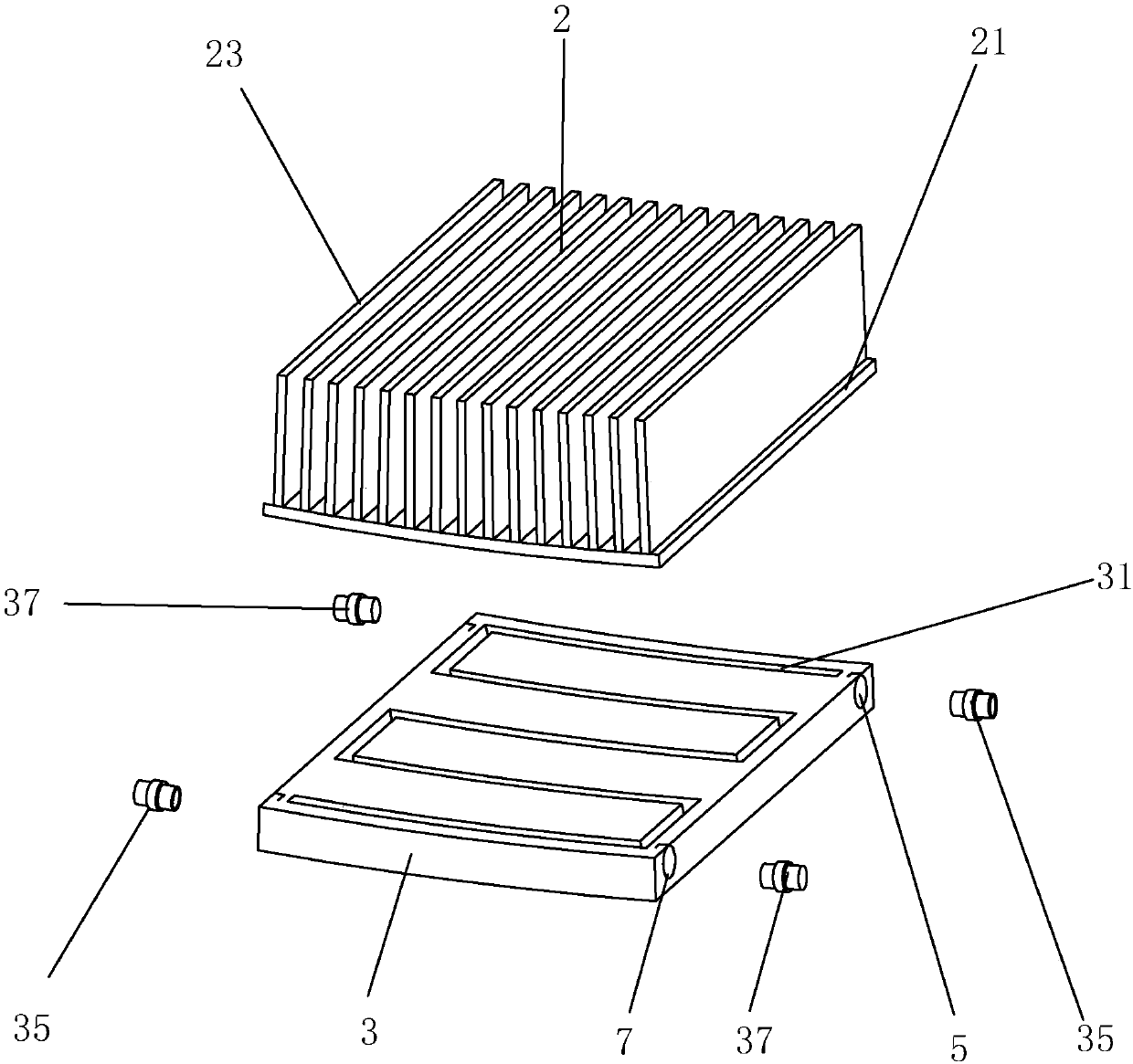

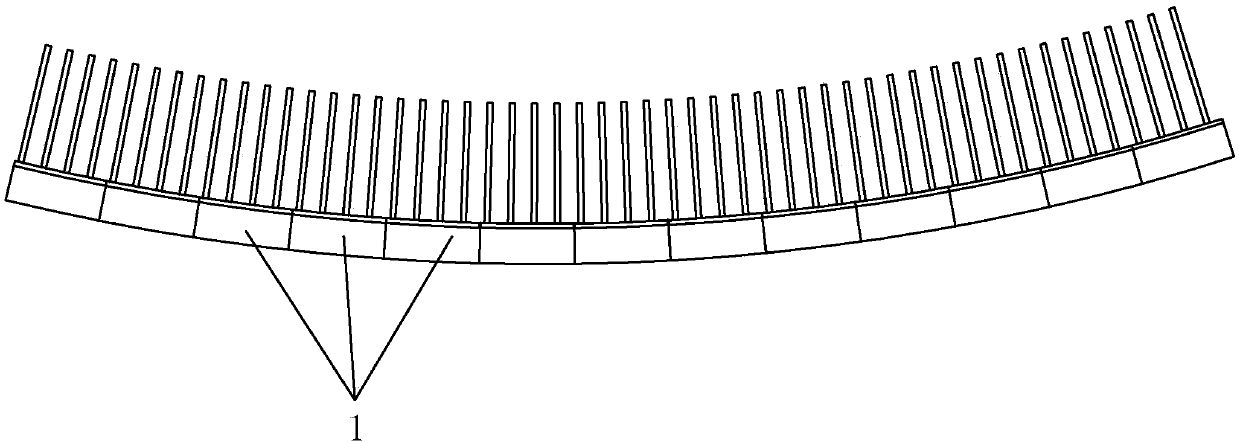

[0025] Please check Figure 1-3 , a kind of lubricating oil radiator installed in front of the turbofan of the aircraft engine of the present embodiment includes a plurality of radiator subunits 1;

[0026] The radiator subunit 1 includes an upper cover 2 and a base 3;

[0027] The upper cover 2 includes a cover plate 21 and a set of ribs, the cover plate 21 is an arc-shaped plate, the set of ribs is arranged on the side of the cover plate 21 facing the center of the circle, and includes a plurality of ribs 23, the The ribs 23 are perpendicular to the upper surface of the cover plate and arranged at intervals along the arc length direction of the cover plate, and an air duct is formed between the two adjacent ribs 23; when the aircraft taxis near the ground, the outside air flows through the air duct to form a natural Refrigerant, used to coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com