Zoom optical tweezers confocal microscopy imaging device and method

A confocal microscope and imaging device technology, applied in microscopes, optics, optical components, etc., can solve the problems of high cost, difficult separation of focal planes, slow modulation speed, etc., to reduce observation costs, improve zoom and axial layer The effect of analysis speed and simple installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

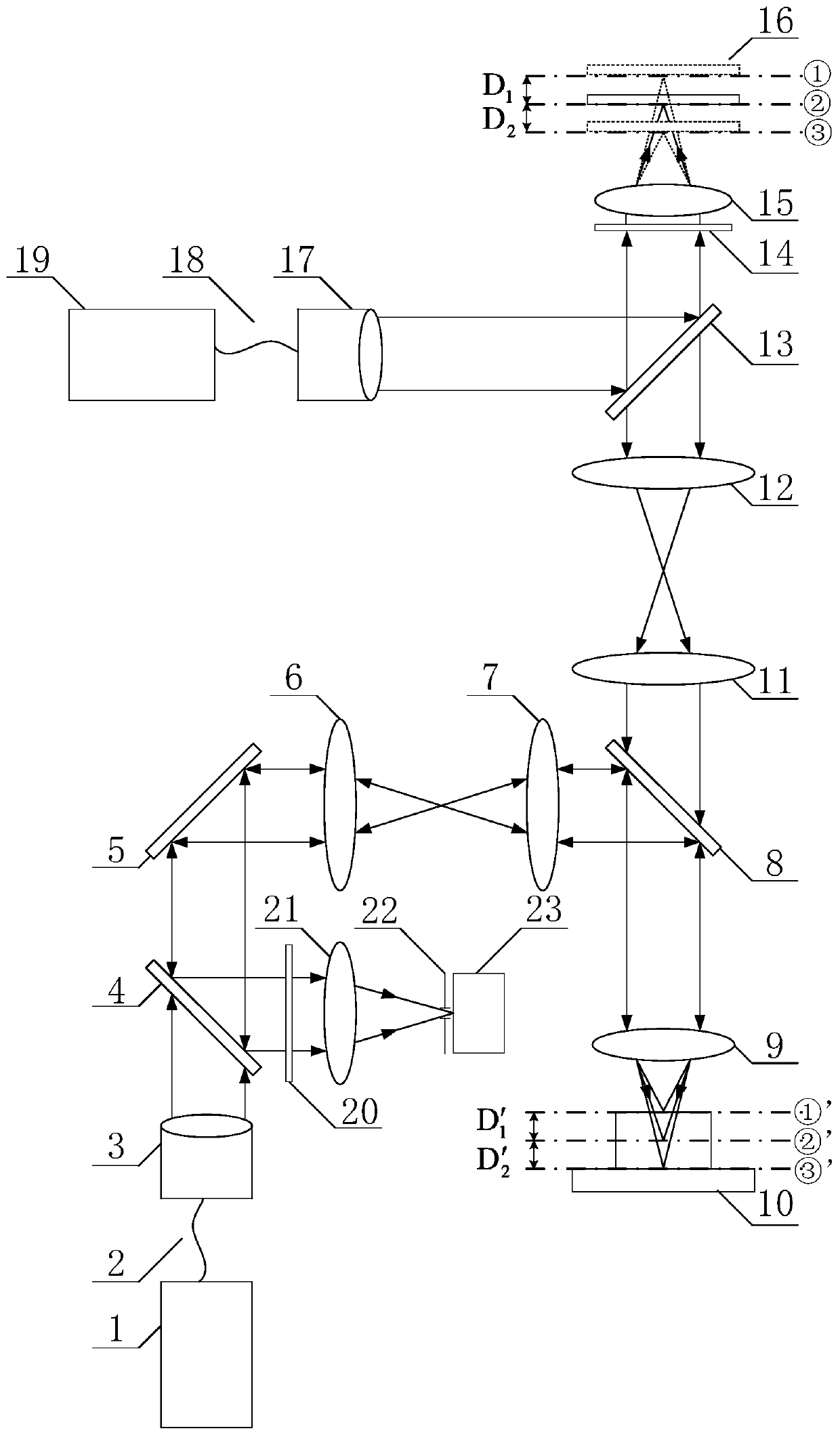

[0030] Embodiment 1: as attached figure 1 The present embodiment shown provides a zoom optical tweezers confocal microscopic imaging device, which is used to quickly switch the axial position to realize three-dimensional tomographic scanning.

[0031] A zoom optical tweezers confocal microscopy imaging device, comprising a confocal illumination module, a confocal scanning module, a confocal detection module, an optical tweezers focusing module and an optical tweezers axial focusing module:

[0032] According to the direction of light propagation, the confocal illumination module is as follows: laser device-1, conduction fiber-2, collimator-3 and dichroic mirror-4;

[0033] The confocal scanning module is in order according to the direction of light propagation: scanning galvanometer 5, scanning lens 6, tube mirror 1 7, dichroic mirror 2 8 and objective lens 1 9;

[0034] The confocal detection module is as follows according to the direction of light propagation: objective len...

Embodiment 2

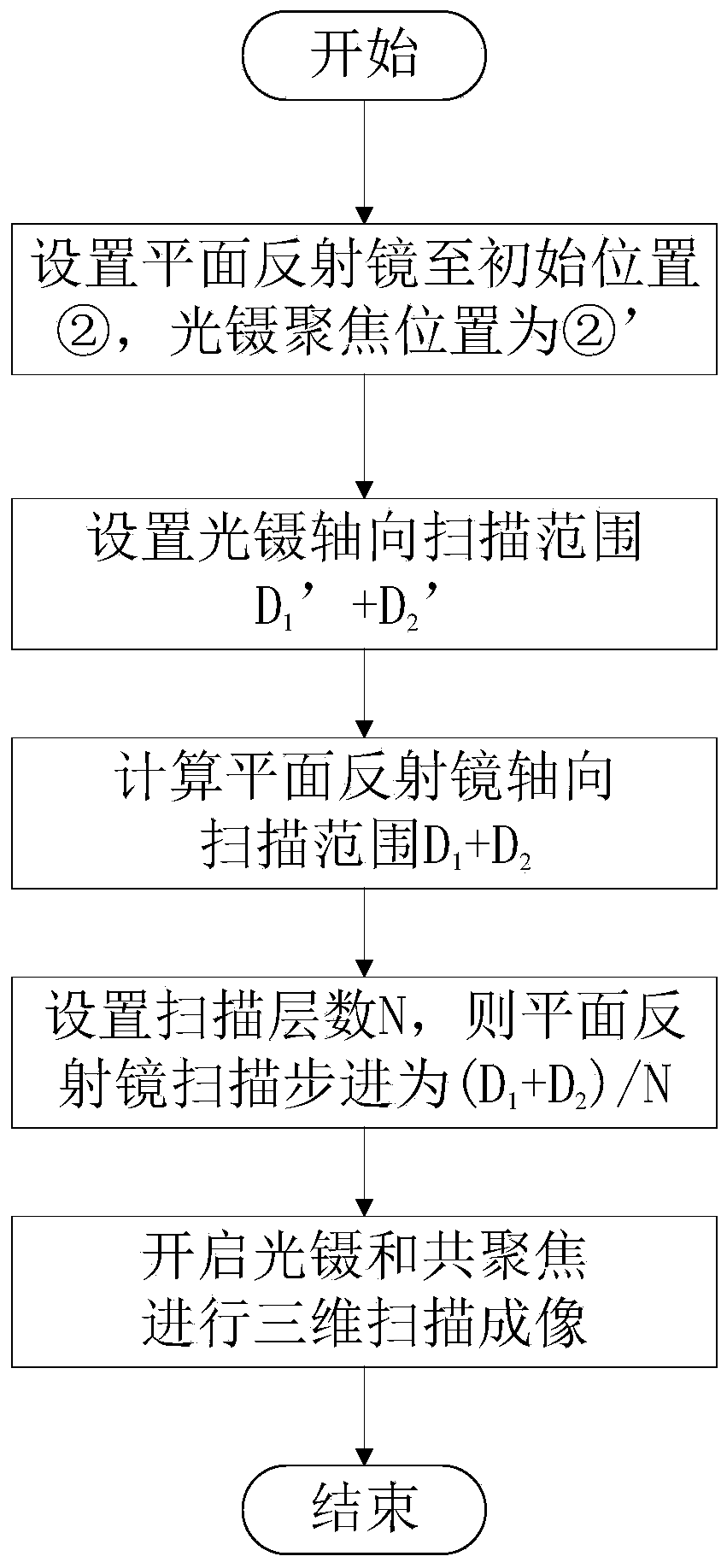

[0046] Embodiment 2: as attached figure 1 and figure 2 The present embodiment shown provides a zoom optical tweezers confocal microscopy imaging method, which is used to quickly switch the axial position to realize three-dimensional tomographic scanning.

[0047] A zoom optical tweezers confocal microscopic imaging method, the method is realized based on the zoom optical tweezers confocal microscopic imaging device described in embodiment 1, specific steps:

[0048] Step a, the laser device-1 emits excitation light, and forms parallel light after passing through the conducting fiber-2 and the collimating mirror-3, and the parallel light beam passes through the dichroic mirror-4, the scanning galvanometer 5, the scanning lens 6, the tube mirror-7, After the dichroic mirror two 8 and the objective lens one 9, a focused spot is formed on the tested sample 10, and the focused spot excites the tested sample 10 to emit fluorescence;

[0049] Step b, the laser device 2 19 emits la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com