Fan-out-shaped packaging structure of large power MOSFET and manufacturing technology

A packaging structure, high-power technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as space that is difficult to improve, and achieve low internal resistance, small stray parameters, and high power density than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

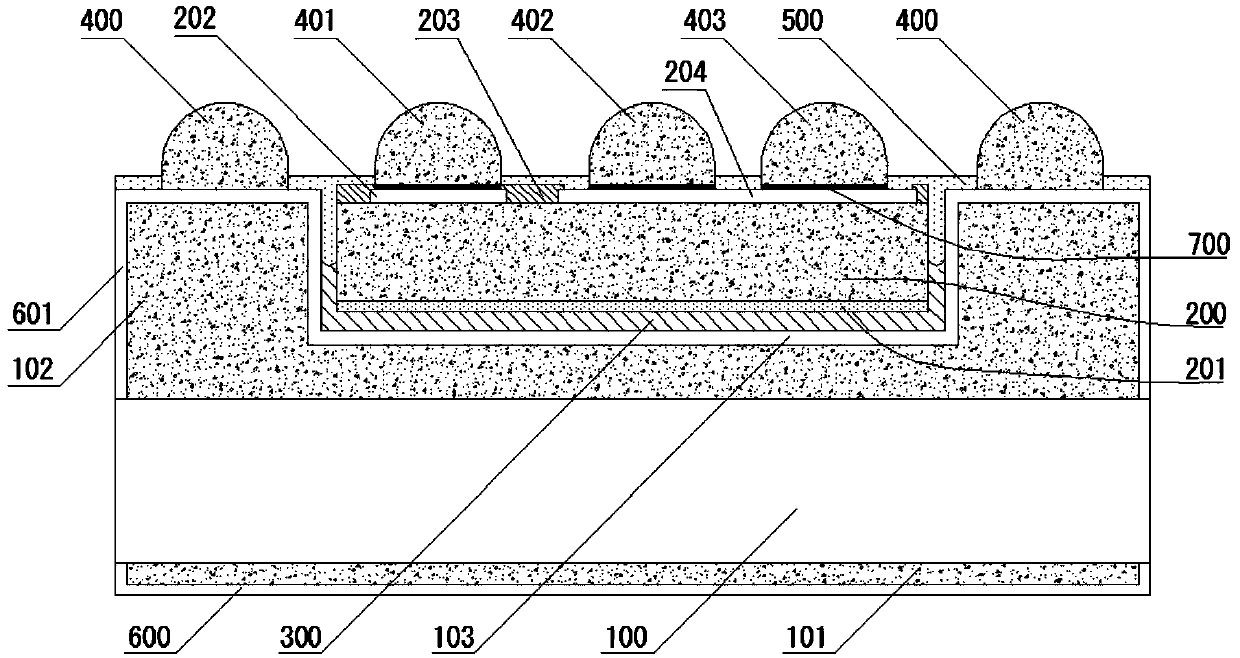

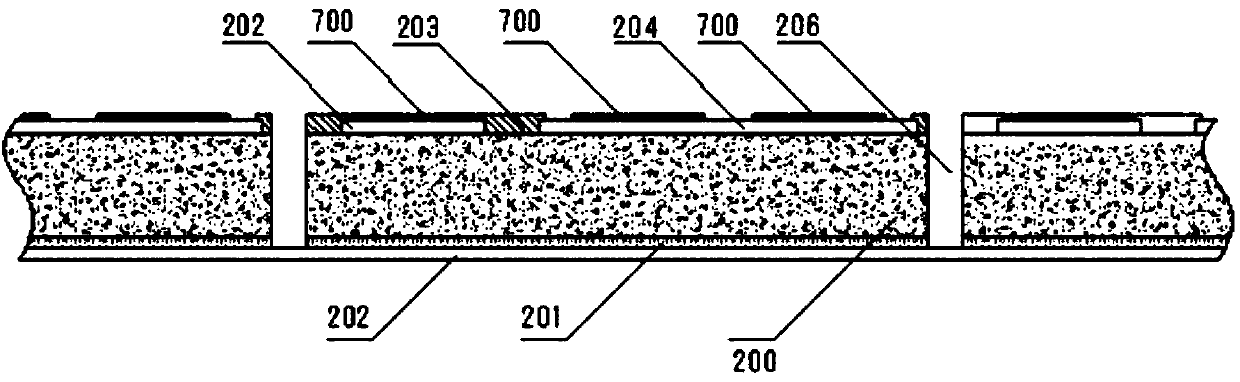

[0032] Embodiments of the present invention provide a fan-out packaging structure for high-power MOSFETs, such as figure 1 As shown, it includes a ceramic double-sided copper-clad substrate, a gold-plated layer 300, a single MOSFET chip 200 formed after dicing a high-power MOSFET wafer, and solder balls arranged in sequence from bottom to top. The ceramic double-sided copper-clad substrate It is provided with a lower embedded groove for a built-in single MOSFET chip 200, and the single MOSFET chip 200 is provided with a gate 202, a source 204 and a drain 201, and the solder balls include a first so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com