Vacuum perfusion method for outer wrapping edge of wind turbine blade

A technology of vacuum infusion, wind power blades, applied in sustainable manufacturing/processing, climate sustainability, household components, etc., can solve the problems of low performance stability, low product mechanical performance, difficult quality control, etc., to improve Labor conditions, increased fiber content, reduced direct contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

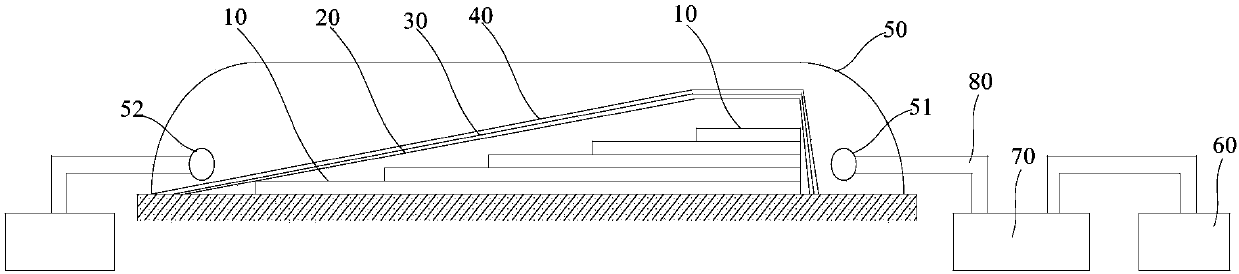

[0055] The present invention provides a method for vacuum pouring of wind turbine blades, wherein the wind turbine blades include a pressure surface and a suction surface, and the pressure surface and the suction surface are arranged opposite to each other. The outer peripheral edges of the pressure surface and the suction surface are connected.

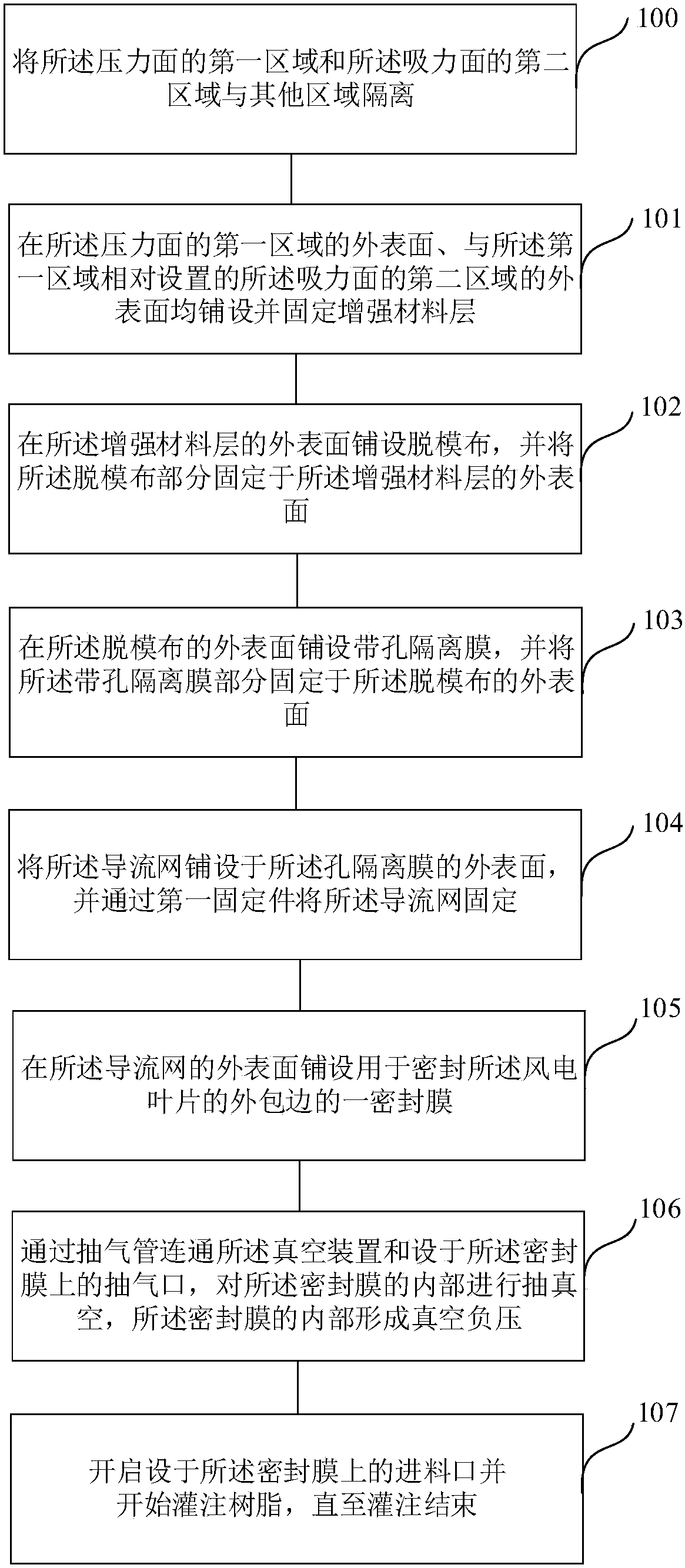

[0056] Such as figure 1 As shown, the outsourcing vacuum perfusion method comprises the following steps:

[0057] Step 100, isolating the first area of the pressure surface and the second area of the suction surface from other areas;

[0058] Step 101, laying and fixing a reinforcing material layer 10 on the outer surface of the first area of the pressure surface and the outer surface of the second area of the suction surface opposite to the first area;

[0059] Step 102, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com