Method for preparing difluoroacetyl fluoride

A technology of difluoroacetyl fluoride and tetrafluoroethane, applied in the field of preparation of difluoroacetyl fluoride, can solve the problems of difficult process, constant change of hydrogen fluoride flow, long fluorination treatment time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

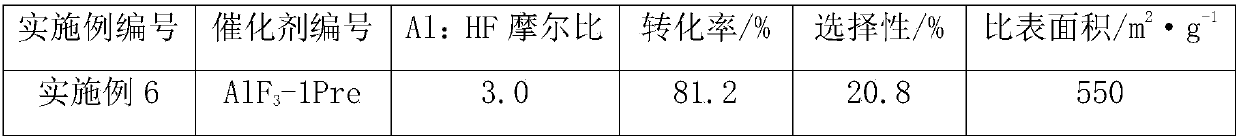

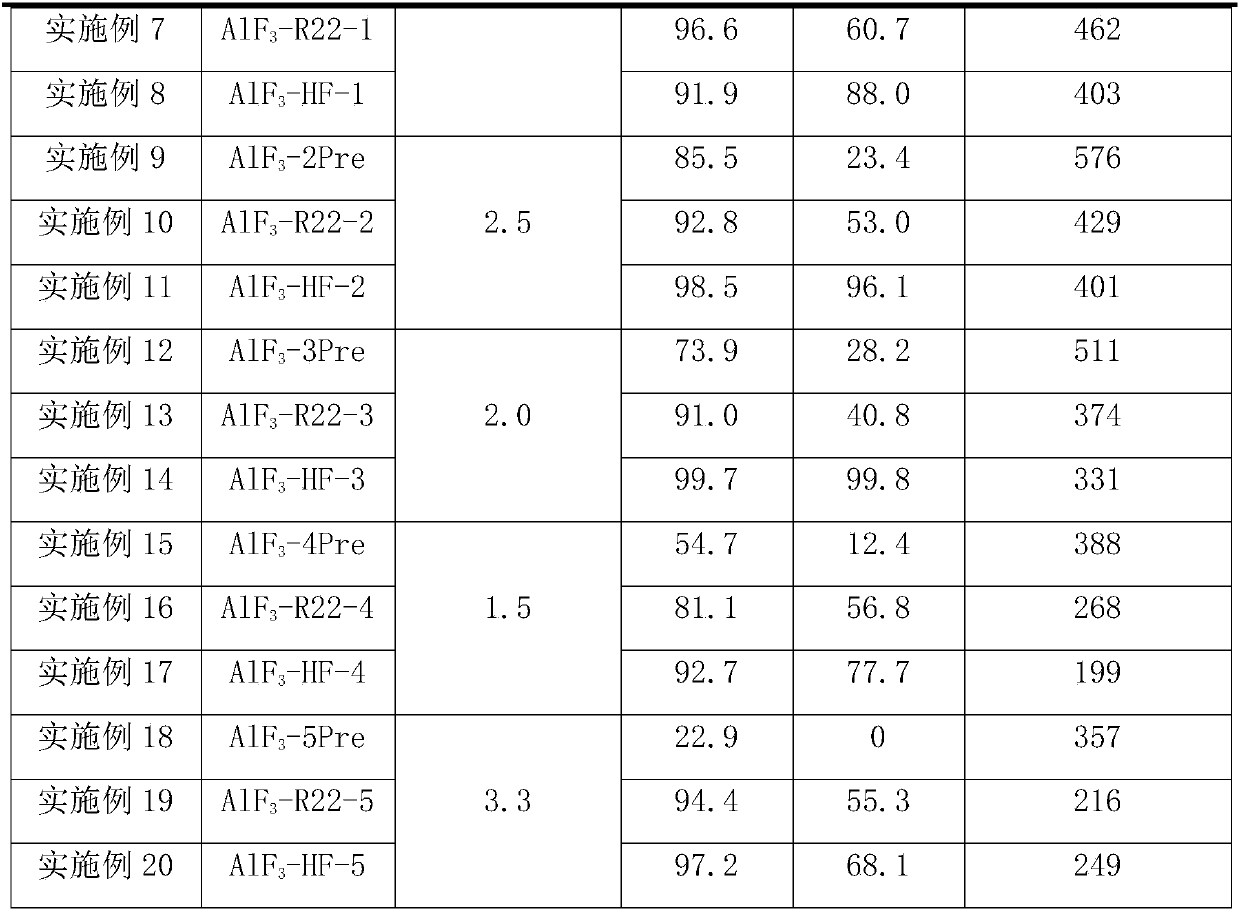

[0031] Embodiment 1: the preparation of aluminum fluoride catalyst

[0032] Take 81.7g Al(i-PrO) 3 Dissolve in 500ml of isopropanol and stir to form an aluminum solution. At room temperature, dissolve 24.0 g of anhydrous HF in HF-Et 2 O solution (12.5mol / L) was added to the above aluminum solution (Al:HF molar ratio was 1:3), stirred vigorously, stopped stirring after 4 hours of reaction, and left to age for 4 hours. Use a rotary evaporator or a centrifuge to remove the volatile components in the product, and dry them in a vacuum oven to obtain a high specific surface area aluminum fluoride precursor, denoted as AlF 3 -1 Pre.

[0033] Take 10ml of the formed aluminum fluoride precursor and place it in a tubular reactor, firstly in N 2 Under the atmosphere, the temperature was raised to 150° C. at an arbitrary rate and kept for 2 hours. In 20% R22 (difluorochloromethane) / 80% N 2 In the atmosphere, the temperature was raised to 200°C at a rate of 1°C / min, and kept for 1 ...

Embodiment 2

[0035] Embodiment 2: the preparation of aluminum fluoride catalyst

[0036] Using the same experimental steps as in Example 1, the Al:HF molar ratio was changed to 1:2.5, and the prepared precursor and aluminum fluoride were respectively marked as AlF 3 -2Pre, AlF 3 -R22-2 and AlF 3 -HF-2.

Embodiment 3

[0037] Embodiment 3: the preparation of aluminum fluoride catalyst

[0038] Using the same experimental steps as in Example 1, the Al:HF molar ratio was changed to 1:2.0, and the prepared precursor and aluminum fluoride were respectively marked as AlF 3 -3Pre, AlF 3 -R22-3 and AlF 3 -HF-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com