Cold-resistant polyurethane shoe sole raw liquid and preparation method

A technology of cold-resistant polyurethane and stock solution, applied in the field of polyurethane materials, can solve the problems of affecting the aesthetics of cold-resistant soles, poor resin fluidity, sole bubbles, etc., and achieve the effects of easy implementation of the preparation method, good fluidity, and reduced bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

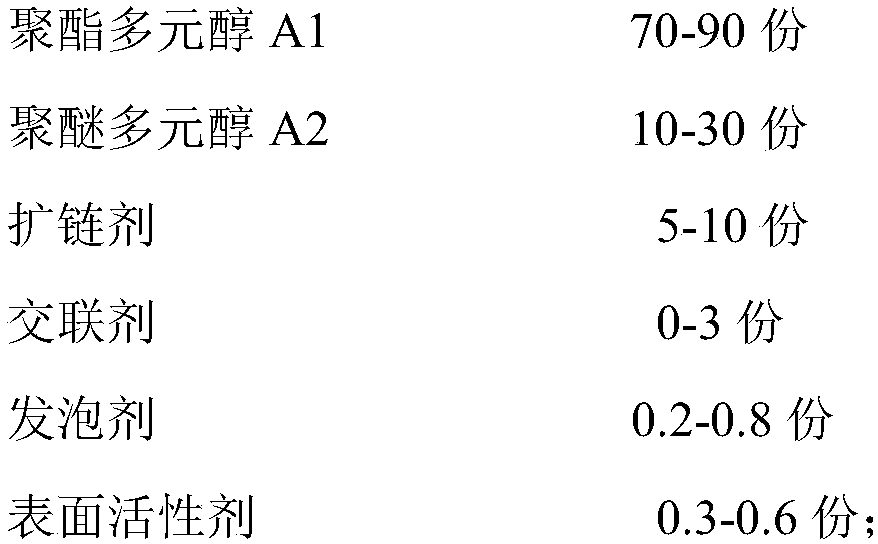

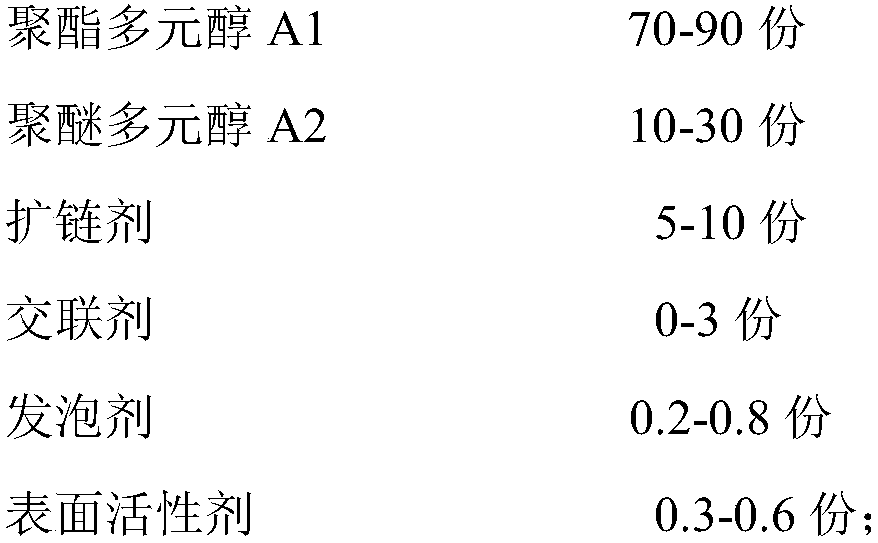

[0033] The preparation method of cold-resistant polyurethane sole stock solution of the present invention is as follows:

[0034] (1) Preparation of component A: weigh PE-2420 to 80.0kg, EP-330NG to 20.0kg, ethylene glycol to 5.0kg, DC2525 to 0.5kg and H 2 O is 0.4kg. Put the weighed PE-2420 and ED-28 into the reaction kettle and stir, then put ethylene glycol, DC2525 and H 2 O, fully stir at 55°C for 3 hours, pack into barrels after passing the inspection, and seal and store to obtain component A;

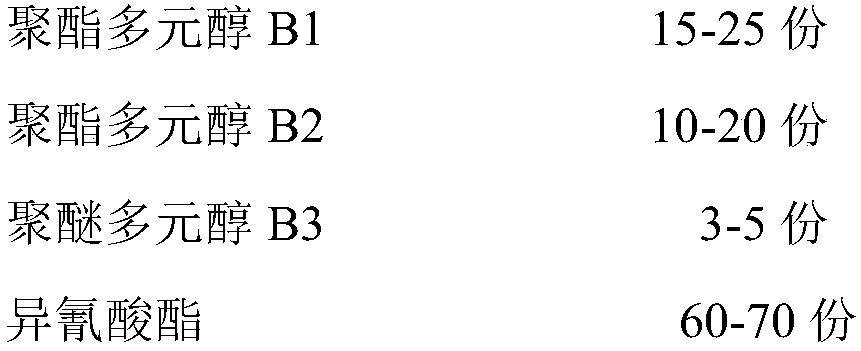

[0035] (2) Preparation of component B: put 25.0kg of PE-2520 and 15.0kg of EP-3600 into the reaction kettle in turn, start stirring and raise the temperature to 90°C, vacuumize to -0.098MPa, dehydrate and degas for 2.0 hours, Cool to 40°C phosphoric acid (accounting for 0.001% of the total weight of component B) and 65kg of MDI-100, raise the temperature to 90°C for 3.0 hours, cool to 40°C after passing the test, put in barrels, and seal and store to obtain the B component;

[...

Embodiment 2

[0038] The preparation method of cold-resistant polyurethane sole stock solution of the present invention is as follows:

[0039] (1) Preparation of component A: Weigh 90.0kg of PE-4020, 10.0kg of EP-3600, 6.0kg of ethylene glycol, 0.4kg of DC193 and H 2 O is 0.5kg. Put the weighed PE-4020 and EP-3600 into the reaction kettle and stir, put in ethylene glycol, DC193 and H 2 O, fully stirred at 50°C for 2 hours, discharged into barrels after passing the inspection, and sealed to obtain component A;

[0040] (2) Preparation of component B: Put 20.0kg of PE-2515, 10.0kg of PE-2325 and 20.0kg of EP-330N into the reaction kettle in turn, start stirring and raise the temperature to 85°C, then vacuumize to -0.098MPa , dehydrate and degas for 3.0 hours, cool down to 40°C and add phosphoric acid (accounting for 0.001% of the total weight of component B), 44C is 60kg, 103C is 20kg, heat up to 85°C and react for 2.5 hours, after passing the test, cool down to 40°C for barreling , seale...

Embodiment 3

[0043] The preparation method of cold-resistant polyurethane sole stock solution of the present invention is as follows:

[0044] (1) Preparation of component A: weigh 70.0kg of PE-5620, 30.0kg of EP-3600, 8.0kg of ethylene glycol, 5.0kg of 1,3-propanediol, 1.5kg of triethanolamine, and 1.5kg of DC6070. 0.3kg and H 2 O is 0.6kg. Put the weighed PE-5620 and EP-3600 into the reactor for stirring, then put in ethylene glycol, DC6070 and H 2 O, fully stirred at 50°C for 3 hours, discharged into barrels after passing the inspection, and sealed to obtain component A;

[0045](2) Preparation of component B: put 25.0kg of PE-2520 and 15.0kg of EP-3600 into the reaction kettle in turn, start stirring and raise the temperature to 70°C, vacuumize to -0.098MPa, dehydrate and degas for 2.0 hours, Cool down to 40°C and add accurately metered phosphoric acid (accounting for 0.001% of the total weight of component B), and 65kg of MDI-100, heat up to 90°C and react for 3.0 hours, after pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com