Cloth defect detection method based on image processing

A technology of image processing and detection method, which is applied in the direction of image data processing, image analysis, and measuring devices, etc., and can solve problems such as obvious defect edges, limited ability to distinguish different types of fabric adaptability, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

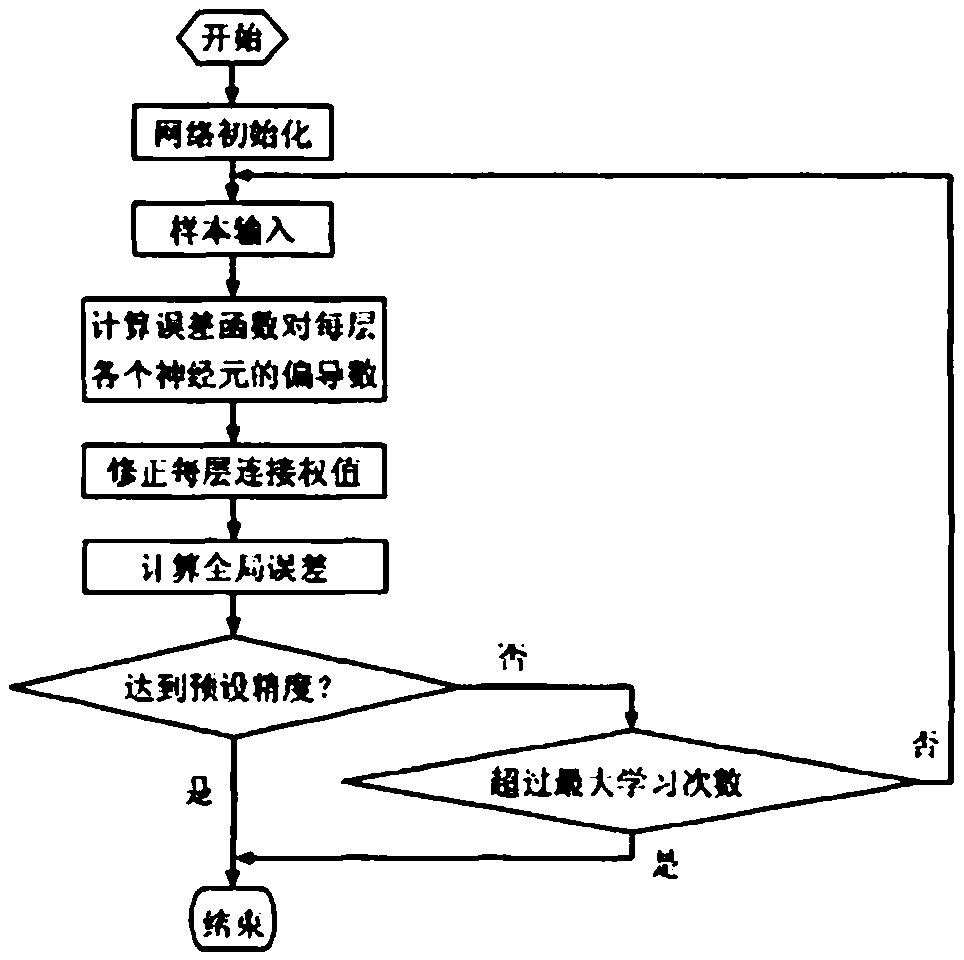

[0109] A cloth defect detection method based on image processing, the method comprises the following steps:

[0110] (3) Adaptive denoising algorithm is adopted according to the actual situation on site;

[0111] (2) Perform sharpening and enhancement processing on the image after denoising in order to enhance the texture details and edge contours of image defects, so that the extraction of subsequent feature values is more reliable;

[0112] (3) Use morphological operations and circulation area marking method to segment image defects, filter and enhance circulation;

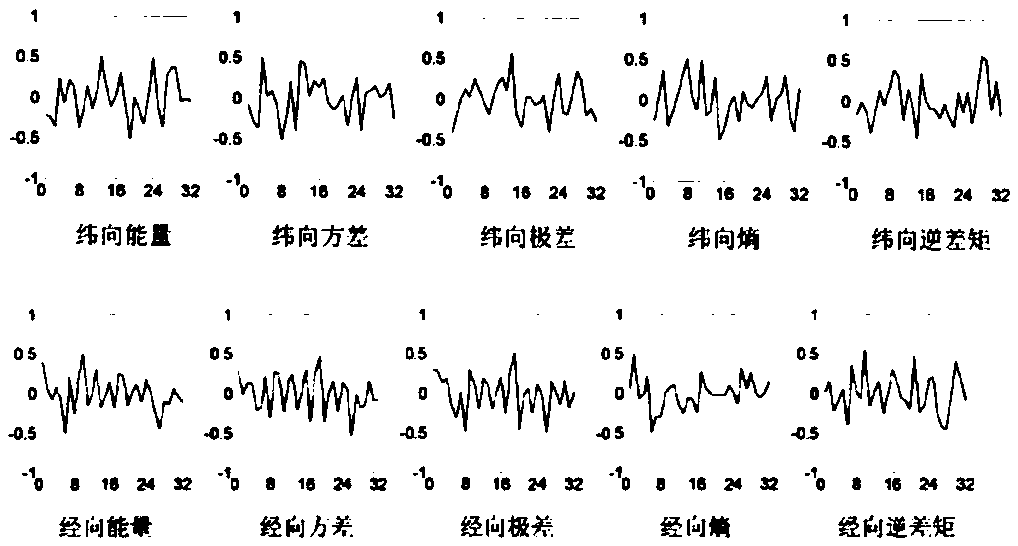

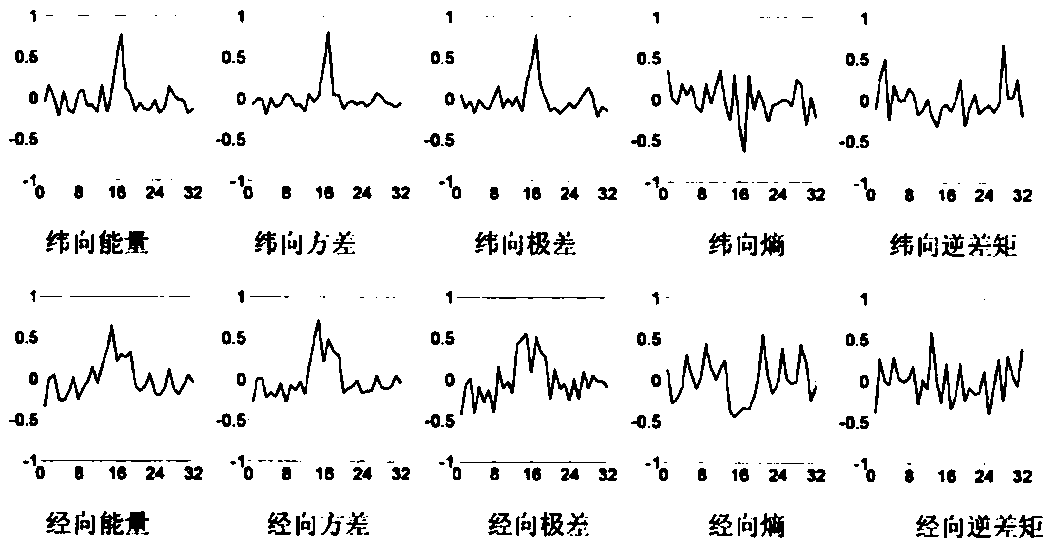

[0113] (4) fabric feature value extraction and normalization;

[0114] (5) Identification and classification of fabric defects.

Embodiment 2

[0116] According to the cloth defect detection method based on image processing described in embodiment 1, the method of step (1) adopting an adaptive denoising algorithm according to the actual situation on the spot is to analyze the noise source and noise characteristics in the fabric image acquisition process, and experiment And correspondingly adopt algorithms such as air domain or frequency domain for preprocessing. If salt and pepper noise dominates, median filtering is adopted. If Gaussian noise dominates, wavelet threshold or Kalman filtering is used for denoising. Depending on the actual effect, the three can also be used. Combined with denoising.

Embodiment 3

[0118] According to the cloth defect detection method based on image processing described in embodiment 1 or 2, step (2) includes using prwiter operator, sober operator, laplace operator, or edge detection operators such as Canny to obtain the defect edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com