Positive pressure concentrated phase pneumatic transmission system control module

A technology of pneumatic conveying system and control module, applied in program control, computer control, general control system, etc., can solve the problems of complex control module, low utilization rate of functional components, unreasonable connection of functional components, etc. Effectively beneficial to the rate improvement and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

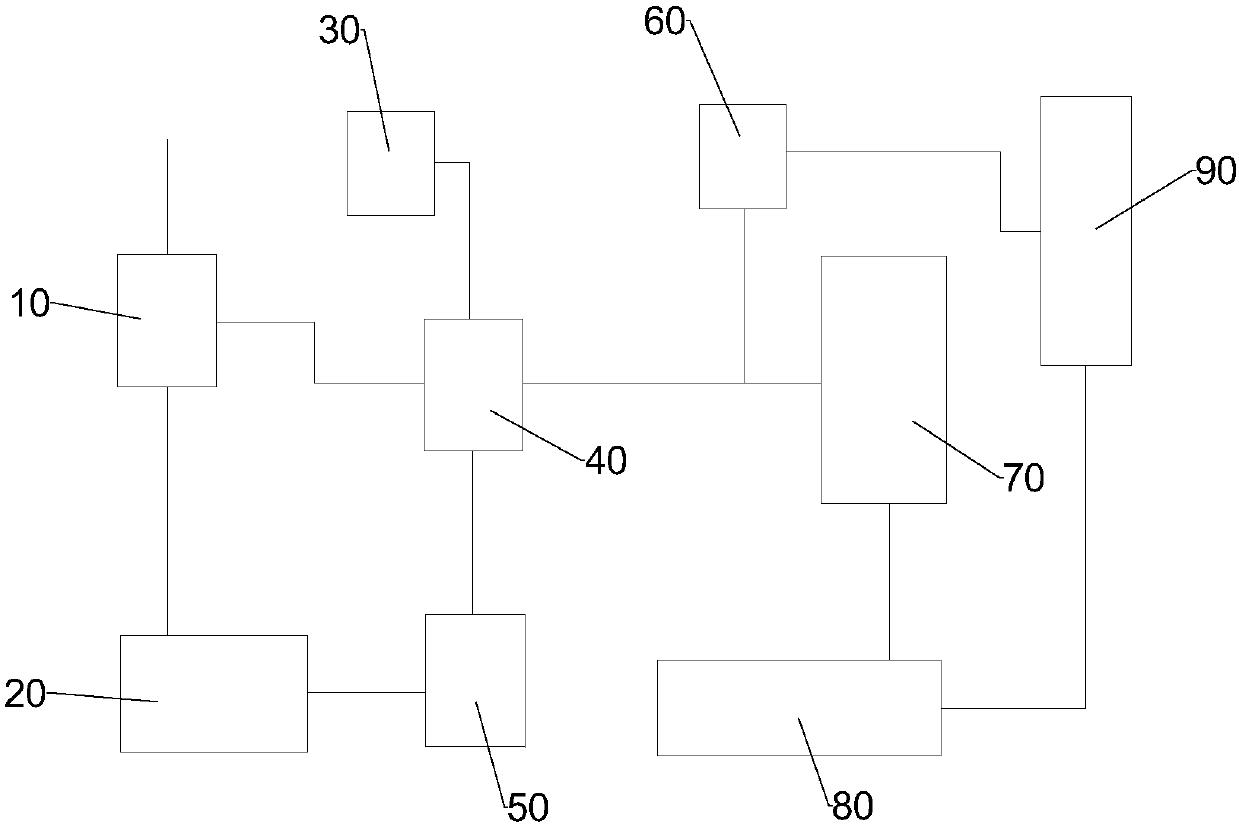

[0012] Such as figure 1 As shown, a positive pressure dense phase pneumatic conveying system control module 1 includes a bus interface 10, the bus interface 10 is connected to a digital potentiometer 20, the digital potentiometer 20 is connected to a coarse adjustment potentiometer 50, and the coarse adjustment potentiometer 50 is connected with a micro-controller 40, and the micro-controller 40 is connected with the bus interface 10, and a photoelectric isolator 30 is also connected on the micro-controller 40, and the micro-controller 40 is connected with a fine-tuning potentiometer 70, and the fine-tuning potentiometer 70 It is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com