Rice-shaped cassava food and preparation method thereof

A cassava and cassava starch technology, applied in the field of food processing, can solve the problems of easy sticking, short cooking time, high viscosity, etc., and achieve the effect of easy ripening, short cooking time and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

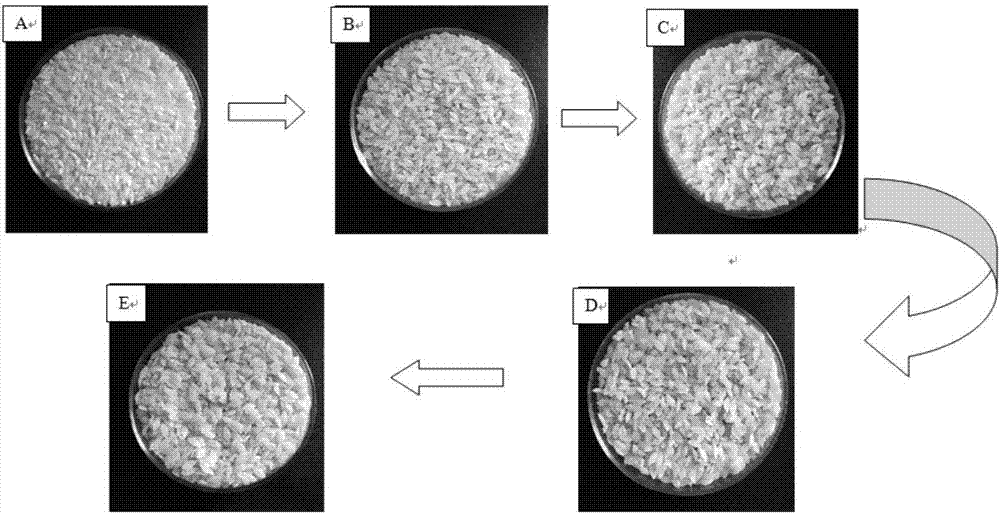

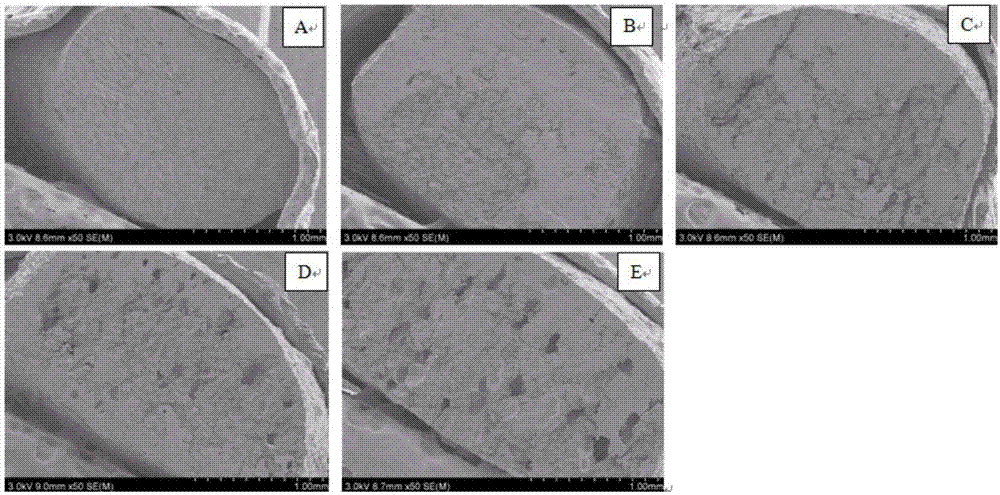

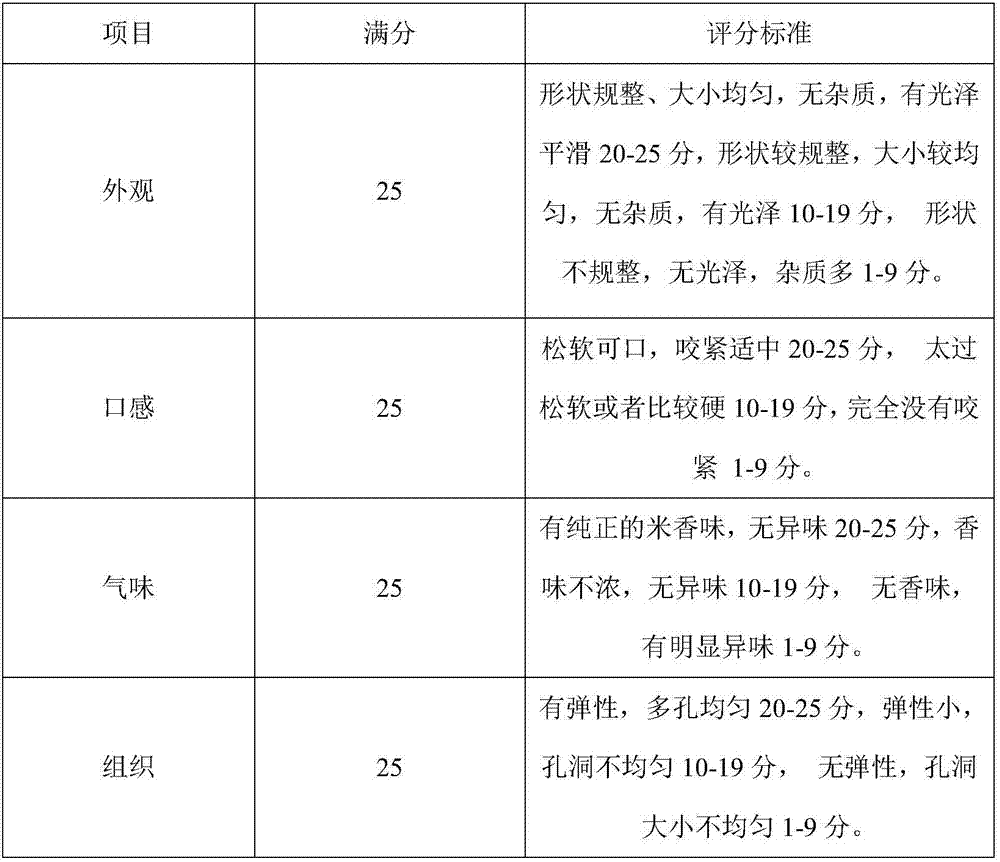

Image

Examples

Embodiment 1

[0039] The ratio of each raw material is as follows: tapioca starch 1kg, early indica rice flour 90kg, glutinous rice 2kg, millet 7kg, Thai fragrant rice 20kg;

[0040] (1) Soak the early indica rice for 30 minutes, grind it into early indica rice flour with a mesh particle size of more than 200 mesh, pour it into a blender together with tapioca starch, add water slowly, allow the material and moisture to fully mix, and control the moisture content at 30wt%;

[0041] (2) Mix and pulverize glutinous rice, millet, and Thai basmati rice into rice flour and also pour it into a blender for stirring, and control the water content at 12wt%;

[0042] (3) Extrusion molding: The uniformly stirred material in step (2) is put into the feeding trough of the extruder, the feeding speed is 25-35kg / min, the material is mixed and preheated in the first zone, and the temperature is 35-55°C , the second zone extrusion conveying, the temperature is 40-65 ℃, the third zone pregelatinization, the t...

Embodiment 2

[0045] The ratio of each raw material is as follows: tapioca starch 1kg, early indica rice flour 90kg, glutinous rice 2kg, millet 7kg, Thai fragrant rice 20kg;

[0046] (1) Soak the early indica rice for 60 minutes, the soaking water temperature is 30°C, grind it into early indica rice flour with a mesh size of 300-400 mesh, pour it into the blender together with tapioca starch, add water slowly, let the material and water fully mix, and control the moisture The content is 35wt%;

[0047] (2) Mix and grind glutinous rice, millet, and Thai basmati rice into rice flour of more than 200 mesh and pour it into a mixer at 400 rpm for 2 hours, and control the water content at 15wt%;

[0048] (3) Extrusion molding: The uniformly stirred material in step (2) is put into the feeding trough of the extruder, the feeding speed is 25-35kg / min, the material is mixed and preheated in the first zone, and the temperature is 35-55°C , the second zone extrusion conveying, the temperature is 40-6...

Embodiment 3

[0051] The ratio of each raw material is as follows: tapioca starch 10kg, early indica rice flour 85kg, glutinous rice 4kg, millet 3kg, Thai fragrant rice 18kg;

[0052] (1) Soak the early indica rice for 60 minutes, the soaking water temperature is 40°C, grind it into early indica rice flour with a mesh size of 300-400 mesh, pour it into the mixer together with tapioca starch, add water slowly, let the material and water fully mix, and control the moisture The content is 32wt%;

[0053] (2) Mix and pulverize glutinous rice, millet, and Thai fragrant rice into 300-mesh rice flour and pour it into a mixer at 300 rpm for stirring for 3 hours, and control the water content at 13wt%;

[0054] (3) Extrusion molding: The uniformly stirred material in step (2) is put into the feeding trough of the extruder, the feeding speed is 25-35kg / min, the material is mixed and preheated in the first zone, and the temperature is 35-55°C , the second zone extrusion conveying, the temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com