Automatic coffee dry bean collection, dehulling, winnowing and bagging integrated machine

An optional bag-packing and all-in-one machine technology, which is applied in the fields of shelling, solid separation, chemical instruments and methods, etc., can solve problems such as storage and use impact, and achieve the effects of saving manpower and material resources, prolonging service life, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

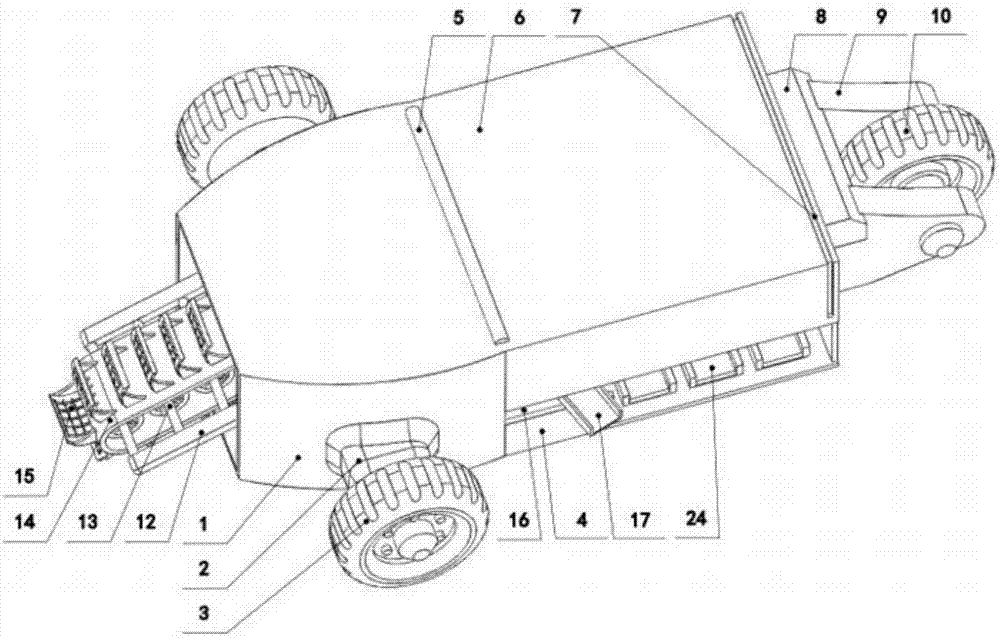

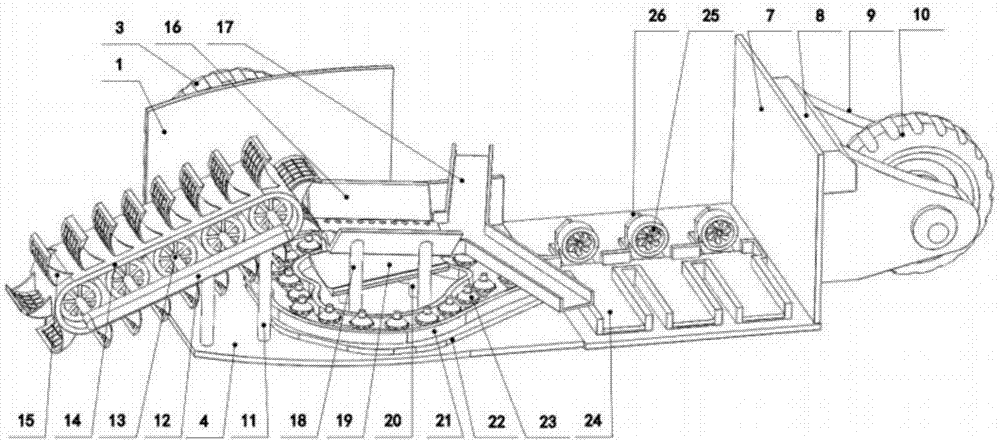

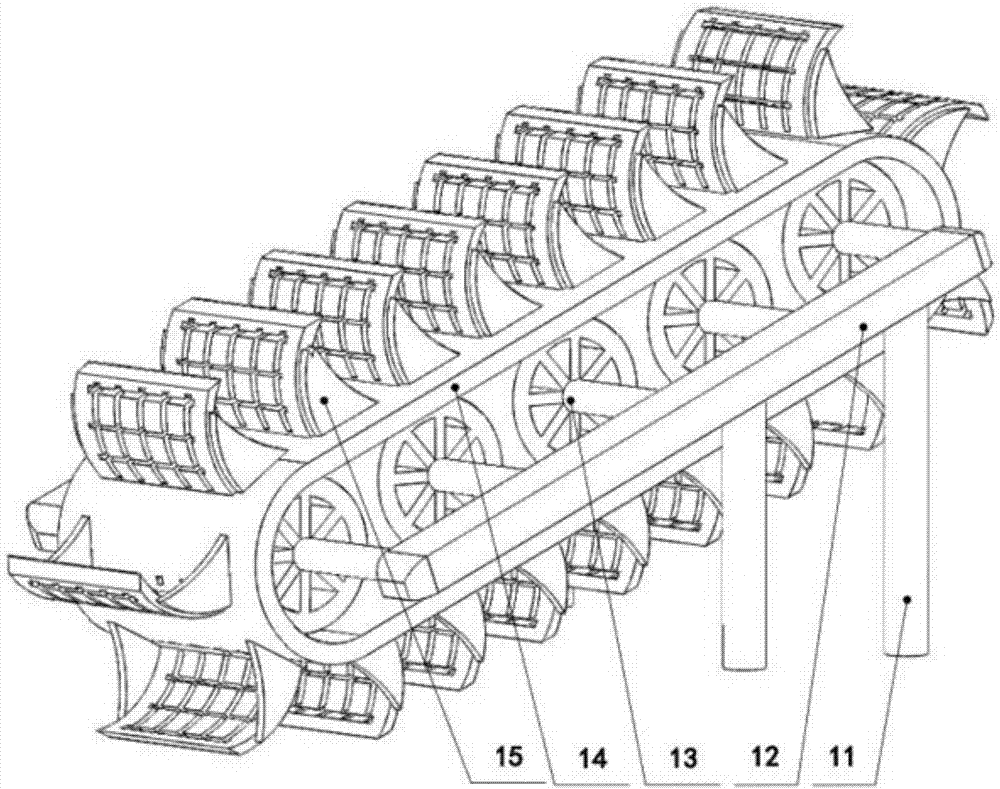

[0035] Such as Figure 1-10 As shown, the automatic coffee dry bean collection, shelling, winnowing and bagging integrated machine includes a casing body, and the casing body is provided with a feeding device, a shelling device and a grading device, and the outlet of the feeding device is connected to the The feed port of the shelling device corresponds, and the discharge port of the shelling device corresponds to the feed port of the grading device. The casing body is composed of a chassis 4, a front guard 1, a middle guard 6 and a rear guard 7. The chassis 4 is provided with a wheel shaft 2, the two ends of the wheel shaft 2 are provided with front wheels 3, a front guard 1 is arranged above the chassis 4 on which the front wheels 3 are installed, and a feeding device is arranged below the front guard 1, and The chassis 4 on the opposite side of the axle 2 is provided with a power frame 9, the power frame 9 is provided with a motor 8 and a power wheel 10, and a rear guard 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com