Dilution device for straw papermaking slurry

A technology of dilution device and slurry, which is used in mixers with rotary stirring devices, transportation and packaging, pre-processing of mixed materials, etc., can solve the problems of reducing the efficiency of subsequent steps, difficult to meet the requirements of the conveying screw, and avoid product quality. very poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

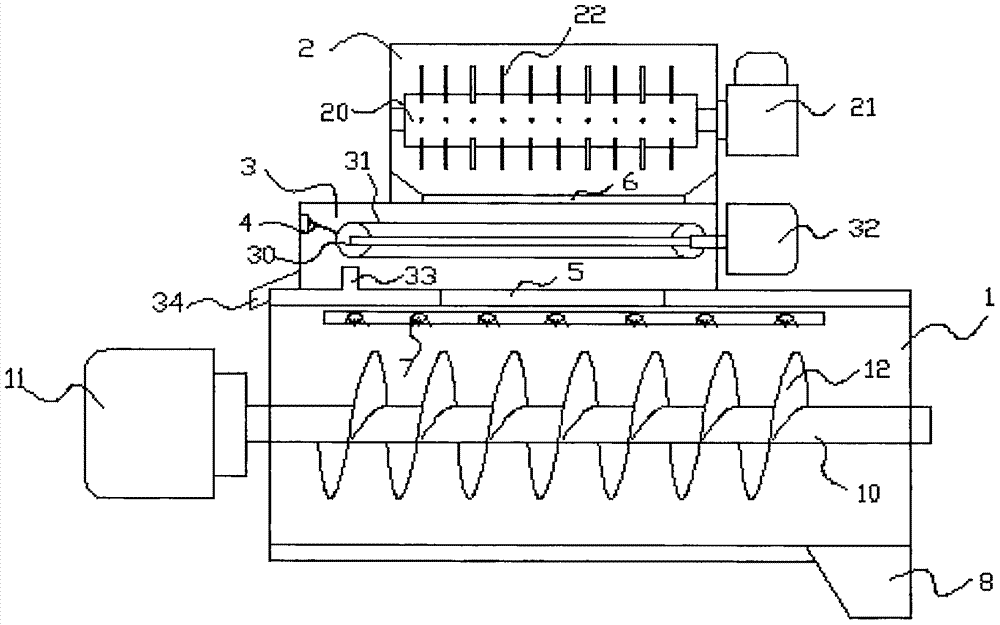

[0015] as attached figure 1 Shown: a dilution device for straw papermaking slurry, including a dilution tank 1, the top of the dilution tank 1 is provided with a feed port 5, and the bottom is provided with a discharge port 8, and the horizontal central axis in the dilution tank 1 is A rotating shaft 10 is installed, and one end of the rotating shaft 10 is provided with a first driving device 11, and the rotating shaft 10 is surrounded by a helical blade 12, and the upper part of the dilution tank 1 is provided with several water spray ports 7; 5, a feed tank body is installed above, and the feed tank body includes an upper crushing tank 2 and a lower filter tank 3, and a crushing roller 20 with crushing teeth 22 is arranged horizontally in the crushing tank 2, and the crushing tank 2 One end of the roller 22 is connected with a second driving device 21, and the bottom of the crushing tank 2 is provided with a discharge port 6 connected to the filter tank 3; the filter tank 3 ...

Embodiment 2

[0017] On the basis of Embodiment 1, a preferred embodiment of the present invention is that two belt rollers 30 distributed horizontally, a belt 31 around the two belt rollers 30 and a roller shaft connecting the belt rollers 30 are provided in the filter tank 3 Vibrating motor 32, described belt 31 is the belt that has mesh screen hole, all the other structures are identical with embodiment 1.

Embodiment 3

[0019] On the basis of Embodiment 2, the preferred embodiment of the present invention also includes that a scraper 4 is arranged on the side wall of the filter tank 3, and the blade of the scraper 4 is close to the surface above the roller shaft of the belt roller 30, and The bottom of the filter tank 3 directly below the belt roller 30 is provided with a protrusion 33, and the rest of the structure is exactly the same as that of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com