Production method and system for flame-retardant self-permeable tipping base paper used for cigarettes

A technology for cigarette tipping paper and its production method, which is applied in the direction of special paper, natural cellulose pulp/paper, applications, etc., and achieves the effect of eliminating the laser drilling process, good flame retardancy, and good printing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

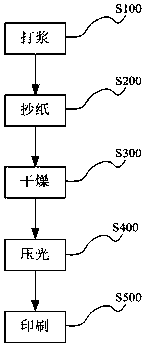

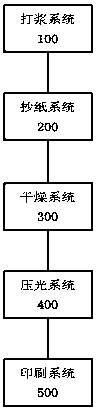

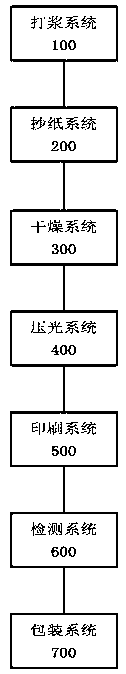

Method used

Image

Examples

Embodiment 1

[0126] Example 1: Preparation of tipping paper base paper for cigarettes with an air permeability of 150CU

[0127] 1. Beating:

[0128] The coniferous pulp is beaten through a double-disc refiner. The double-disc refiner is 4 TF20 double-disc refiners. The first two double-disc refiners are cut-off disc refiners, and the latter two are broom disc refiners. 0 SR, the wet weight is 7g, and the eucalyptus pulp is thawed by a double disc mill, and the beating concentration is 20 0 SR, wet weight is 1g;

[0129] Mix the treated coniferous pulp and eucalyptus pulp according to the ratio of 35% by weight: 65% to make a joint pulp;

[0130] Add 30% of its total weight of calcium carbonate and 1.4% of wet strength agent to the joint slurry to make a mixed slurry.

[0131] 2. Papermaking:

[0132] Dilute the mixed beating material with water to a concentration of 0.9% by weight, then add 0.5% by weight of dispersant and 1.5% by weight of AKD, and pass through the bottom net of 12-1...

Embodiment 2

[0146] Example 2: Preparation of tipping paper base paper for cigarettes with an air permeability of 200CU

[0147] 1. Beating:

[0148] The coniferous pulp is beaten through a double-disc refiner. The double-disc refiner is 4 sets of TF20 double-disc refiners. The first two double-disc refiners are cut-off disc refiners, and the latter two are broom disc refiners. The beating concentration is 70 0 SR, the wet weight is 8g, and the eucalyptus pulp is thawed by a double disc mill, and the beating concentration is 18 0 SR, wet weight is 1g;

[0149] Mix the treated coniferous pulp and eucalyptus pulp according to the ratio of 32% by weight: 68% to make a joint pulp;

[0150] Add 40% of its total weight of calcium carbonate and 1.4% of wet strength agent to the joint slurry to make a mixed slurry.

[0151] 2. Papermaking:

[0152] Dilute the mixed beating material with water to a concentration of 0.9% by weight, then add 0.5% by weight of dispersant and 1.5% by weight of AKD,...

Embodiment 3

[0166] Example 3: Preparation of tipping paper base paper for cigarettes with an air permeability of 250CU

[0167] 1. Beating:

[0168] The coniferous pulp is beaten through a double-disc refiner. The double-disc refiner is 4 sets of TF20 double-disc refiners. The first two double-disc refiners are cut-off disc refiners, and the latter two are broom disc refiners. 0 SR, the wet weight is 8g, and the eucalyptus pulp is thawed by a double disc mill, and the beating concentration is 15 0 SR, wet weight is 1g;

[0169] Mix the processed coniferous pulp and eucalyptus pulp according to the ratio of 30% by weight: 70% to make a joint pulp;

[0170] Add 50% of its total weight of calcium carbonate and 1.4% of wet strength agent to the joint slurry to make a mixed slurry.

[0171] 2. Papermaking:

[0172] Dilute the mixed beating material with water to a concentration of 0.9% by weight, then add 0.5% by weight of dispersant and 1.5% by weight of AKD, and pass through the bottom n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smoothness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com