Explosionproof lithium battery compartment

A lithium battery and cabin technology, which is applied in the field of explosion-proof lithium battery compartment, can solve the problems that lithium batteries are easily flammable, easily guided by external flames and even explode, and achieve the effects of avoiding deliquescence, avoiding blockage and increasing air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

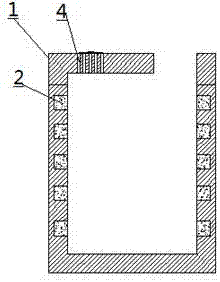

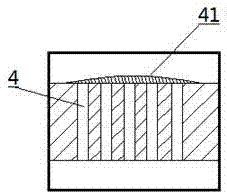

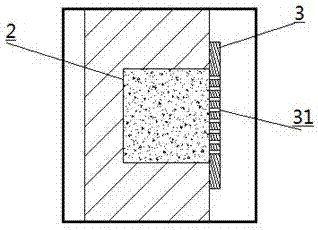

[0020] This embodiment provides an explosion-proof lithium battery compartment, such as figure 1 , 2 , 3, including a hollow cabin body 1, the surface of the inner wall of the cabin body 1 is provided with a recessed accommodation groove 2, and a cover sheet (metal sheet can be selected) 3 is provided at the opening of the accommodation groove 2, and an array of rows is arranged on the cover sheet 3. The pores 31 of the cloth; the holding tank 2 is filled with sodium bicarbonate powder. The cabin body also includes other necessary structures, such as openings for passage of lines. The inner wall of the cabin is also provided with pressure relief through holes 4 distributed in an array; the outside of the pressure relief through holes is covered with a latex film 41 . The latex film expands as Figure 4 shown.

Embodiment 2

[0022] This embodiment provides an explosion-proof lithium battery compartment, with respect to Embodiment 1, such as Figure 5 Preferably, there is an installation area around the edge of the receiving tank in this embodiment, and a plurality of blind holes 51 are provided on the installation area; bosses 52 are provided on the positions of the cover corresponding to the blind holes, and the cover is embedded through the bosses. The blind hole is internally fixed; the boss is in interference fit with the blind hole.

[0023] Preferably, the radius of the air hole decreases along the outer side of the cover sheet toward the receiving groove; the radius of the air hole at its widest position is 5-10 times that of the narrowest position.

Embodiment 3

[0025] This embodiment provides an explosion-proof lithium battery compartment, the structure of which is consistent with that of Embodiment 2.

[0026] In particular, the containing tank of this embodiment is also filled with superabsorbent resin powder and activated carbon powder, and the mass ratio of superabsorbent resin, activated carbon powder and sodium bicarbonate powder is 0.2:1:7. In this embodiment, the superabsorbent resin powder is an acrylate superabsorbent resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com