Tree trunk whitening device with whitening liquid recycling function

A technology of whitening and whitening of tree trunks, which is applied in spraying devices, horticulture, botanical equipment and methods, etc., can solve the problems of waste of whitening liquid, affect the efficiency of whitening, and high labor intensity, so as to reduce labor intensity, Improve efficiency and avoid clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

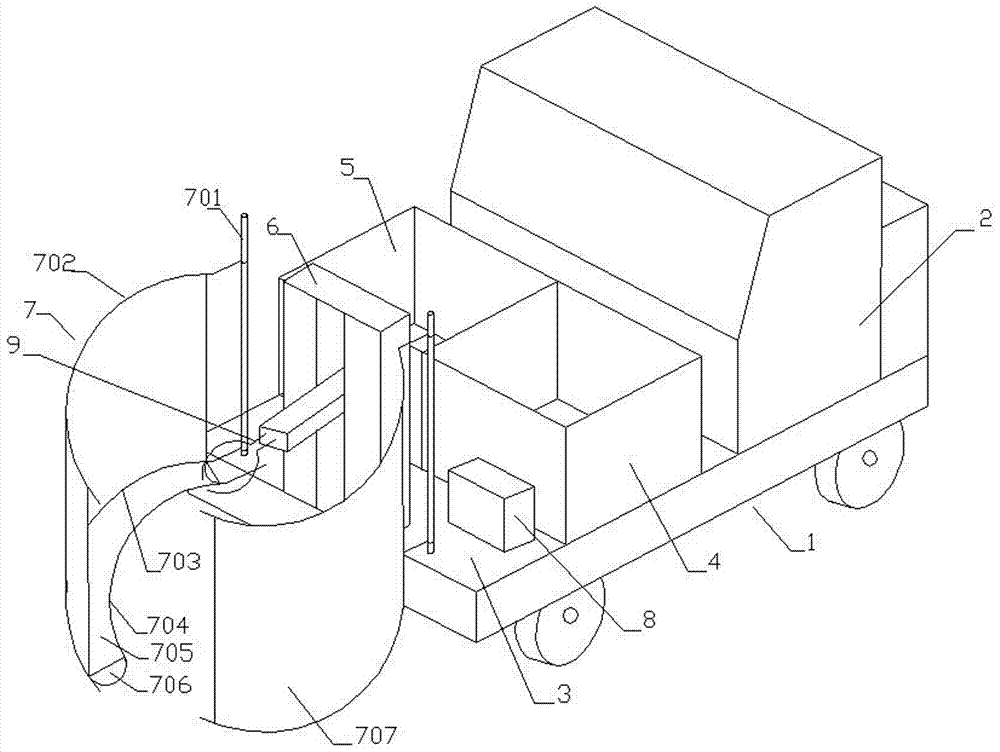

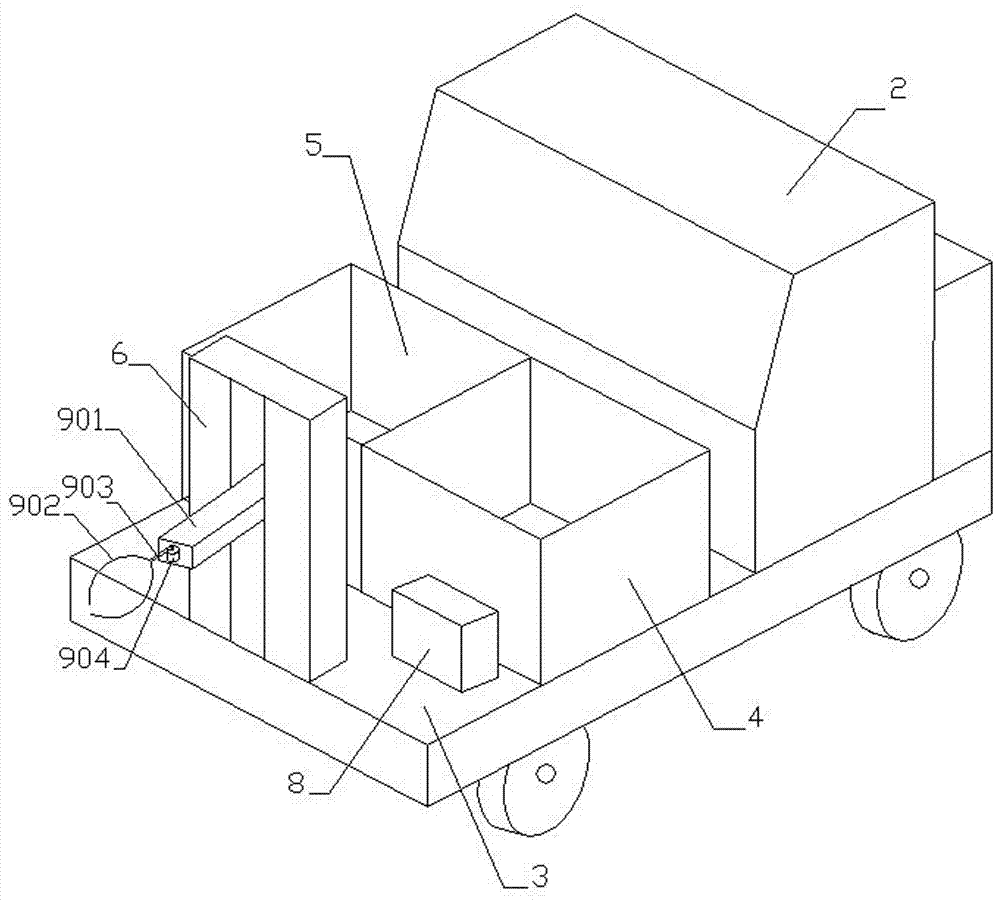

[0026] The technical solutions of the present invention will be further explained through specific implementations in conjunction with the accompanying drawings. The following "front" and "rear" refer to the forward direction of the vehicle body, the forward direction is forward, and vice versa. .

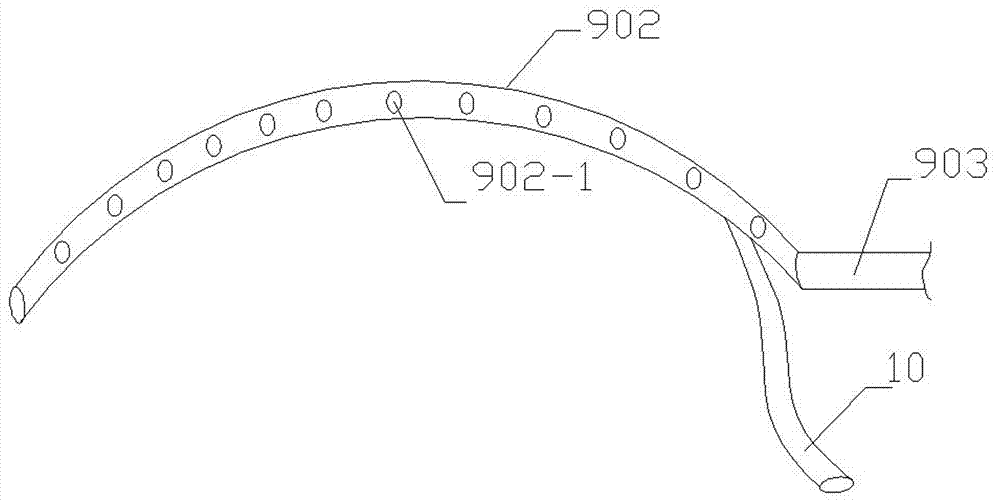

[0027] As shown in the figure, a trunk whitening device with whitening liquid recovery function includes a power car body 1. The power car body 1 includes a rear cab 2 and an engine and a front whitening system. The power car body 1 The front part is equipped with an installation platform 3 for installing the whitening system. The whitening system includes a hydraulic lifting mechanism 6, a spraying mechanism 9, a material tank 4, an electric pump 8 and a whitening liquid recovery mechanism 7. The spraying mechanism 9 includes a cantilever 901 and a A pair of arc-shaped tubes 902 on the cantilever 901. The arc-shaped tube 902 has a hollow cavity. The inner circle of the arc-shaped tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com