Inner wall cleaning method for pipes

A technology for pipe fittings and cleaning mechanisms, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that the inner wall of pipe fittings is not easy to clean, and achieve the effect of avoiding surface wear and improving impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

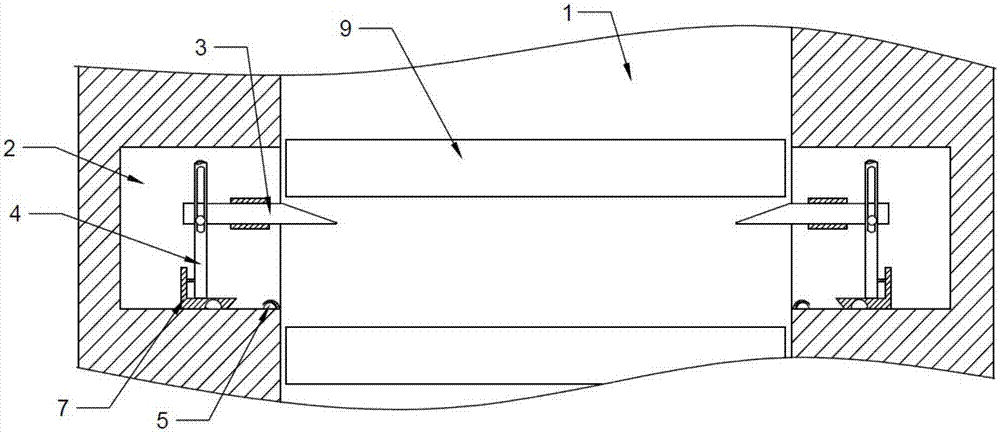

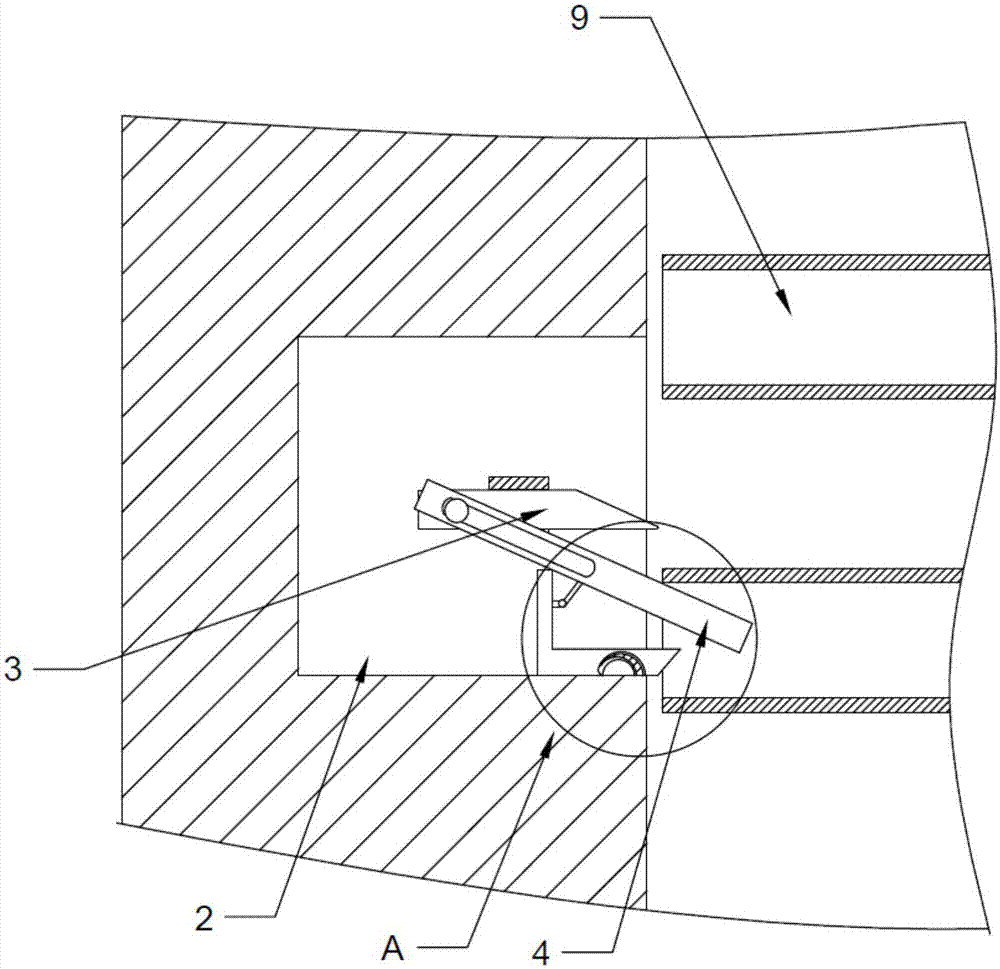

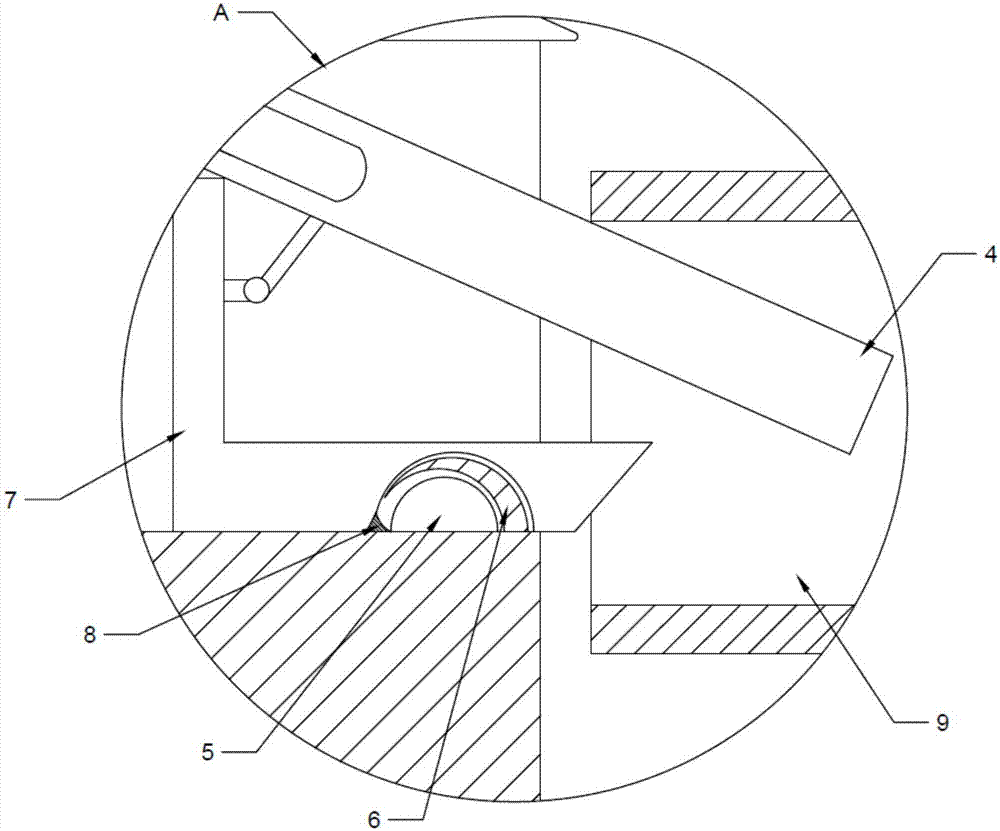

[0022] The reference signs in the accompanying drawings include: through hole 1 , slot hole 2 , wedge block 3 , connecting pipe 4 , contact switch 5 , arc-shaped cover 6 , starting plate 7 , driving plate 8 , and pipe fitting 9 .

[0023] The concrete steps of this method are as follows:

[0024] Step 1: Preparation of cleaning solution components: 55kg of ethanol, 8kg of diethylenetriamine, 4kg of acetone, 10kg of pine oil, 6kg of diatomaceous earth, 3kg of sodium linear alkylbenzene sulfonate, and 2kg of defoamer;

[0025] Step 2: Put the components in step 1 in a container and stir for a total of 60 minutes to obtain a cleaning solution for later use; after stirring for 30 minutes, add 0.5 kg of deionized water, and divide the diatomaceous earth into the container twice , before stirring, put 4kg of diatomite into the container and stir at the same time. After stirring for 20 minutes, add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com