A high-performance water-based metal die-casting release agent

A release agent, metal technology, applied in the direction of metal processing equipment, casting molds, casting mold components, etc., can solve problems such as difficult to ensure the residual amount of lubricating components, burrs, pores, etc., to facilitate automated production, solve porous problems, high temperature The effect of strong heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of metal die-casting release agent of the present invention comprises the steps:

[0038] Oil phase system mixing: add the functional organic composition and the nonionic surfactant into the multifunctional reaction kettle, and stir to form an oil phase system at the same time;

[0039]W / O water-in-oil: Stir at 1000r / min, and drop water into the oil phase system to form a water-in-oil system. The amount of water added accounts for 1 / 10 of the mass of the oil phase system. The water-in-water system undergoes phase transformation to form an O / W oil-in-water system. After the phase transformation, stop adding water to the oil phase system and continue stirring for 5-10 minutes;

[0040] O / W oil-in-water: continue to inject water into the oil-in-water system for 3-5 minutes, the amount of water injected is 1 / 3-1 / 2 of the oil phase system, and the speed is increased to 1500r / min to make oil-in-water O / W W pre-emulsion, increase the speed to 600r / min, ...

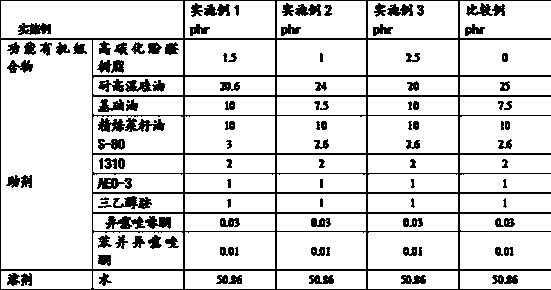

Embodiment 1

[0044] Example 1 is a specific example of preparing a mold release agent suitable for aluminum alloy die-casting. As shown in the following table 1, 1.5 phr high carbonized phenolic resin contained in this example, 20.6 phr high temperature resistant silicone oil, 10.0 phr refined rapeseed oil, 10.0 phr high viscosity mineral oil, 3.0 phr Span-80, 2.0 phr 1310 , 1.0 phr AEO-3, 1.0 phr triethanolamine, 0.03 phr isothiazolinone, 0.01 phr benzisothiazolone and 50.86 phr solvent.

[0045] Concrete preparation process is as follows:

[0046] Add high-carbonized phenolic resin, high-temperature-resistant silicone oil, high-viscosity mineral oil, refined rapeseed oil, Span-80, AEO-3 and 1310 into the multifunctional reaction kettle, and heat and stir to form an oil phase system at the same time. Then stir at a speed of 1000r / min, and add water dropwise into the oil phase system, and the dropwise addition is completed within 20 minutes to form an oil-in-water system. Continue to inj...

Embodiment 2

[0049] Example 2 is a specific example of preparing a release agent suitable for aluminum alloy die-casting. As shown in the following table 1, 1.0 phr high carbonized phenolic resin contained in this example, 24.0 phr high temperature resistant silicone oil, 10.0 phr refined rapeseed oil, 7.5 phr high viscosity mineral oil, 2.6 phr Span-80, 2.0 phr 1310 , 1.0 phr AEO-3, 1.0 phr triethanolamine, 0.03 phr isothiazolinone, 0.01 phr benzisothiazolone and 50.86 phr solvent.

[0050] Concrete preparation process is as follows:

[0051] Add high-carbonized phenolic resin, high-temperature-resistant silicone oil, high-viscosity mineral oil, refined rapeseed oil, Span-80, AEO-3 and 1310 into the multifunctional reaction kettle, and heat and stir to form an oil phase system at the same time. Then stir at a speed of 1000r / min, and add water dropwise into the oil phase system, and the dropwise addition is completed within 20 minutes to form an oil-in-water system. Continue to inject wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com