Belt pulley and manufacturing method thereof

A manufacturing method and a pulley technology, applied in the field of mechanical parts processing, can solve the problems of reducing material cost, production cost, environmental pollution, and high cost of pulley, and achieve the effects of reducing cost input, reducing environmental pollution, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

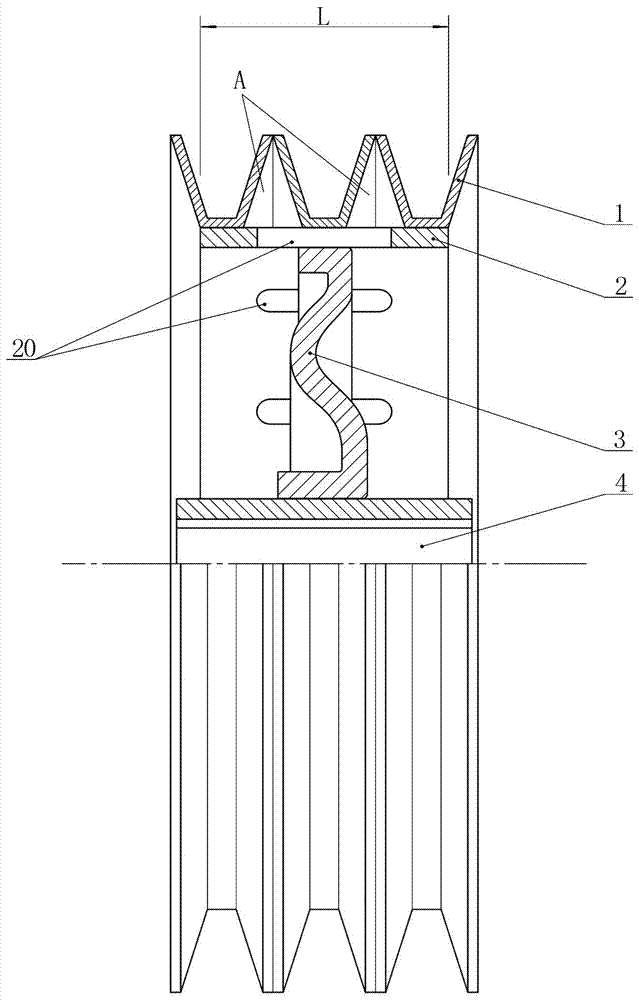

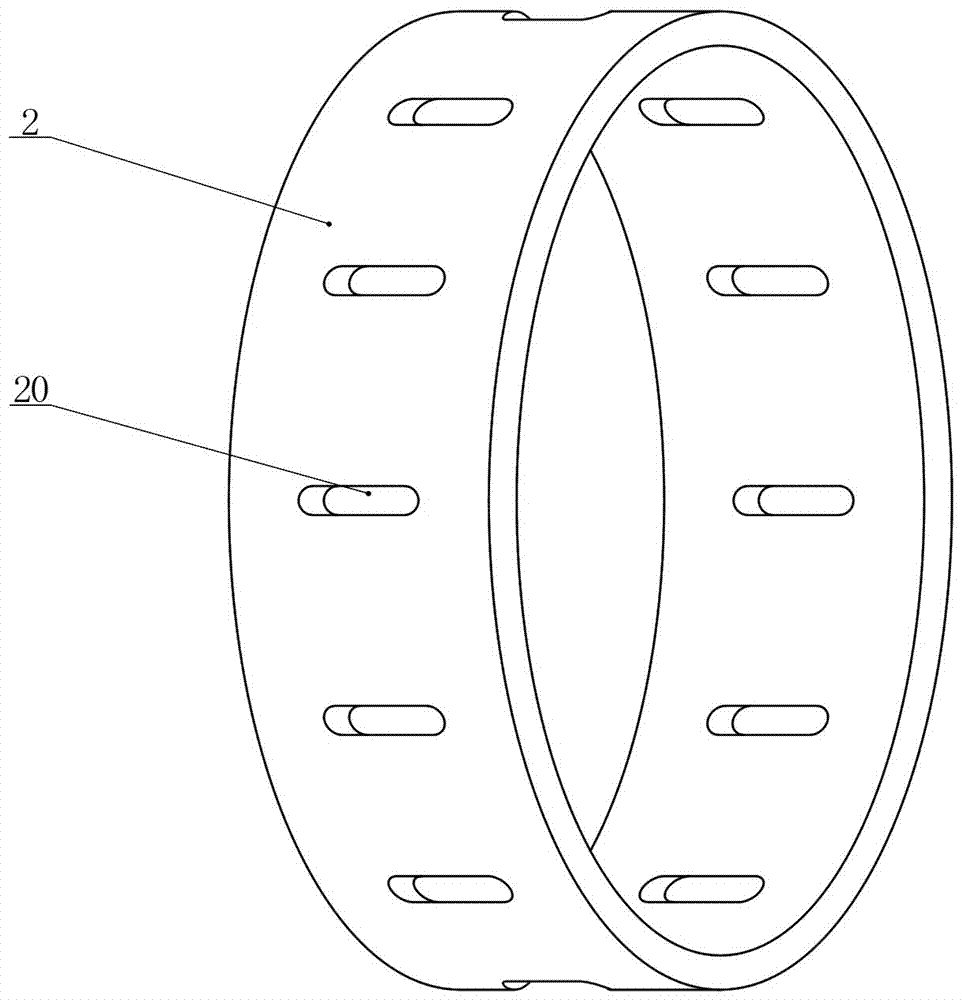

[0040] The manufacturing method of the pulley of the present invention is as follows: Utilize the metal sheet to press the belt groove ring body 1, the rim ring body 2, and the spoke plate body 3 with at least one annular belt groove, and then make the belt groove ring body 1, the rim ring body 2, The spoke plate body 3 and the axle sleeve 4 are welded together to form a belt pulley.

[0041] In this embodiment, the V-belt pulley with three belt grooves is taken as an example to describe the processing process in detail. The steps are as follows:

[0042] a. Preparation of billets

[0043] The blank of the belt groove: use the shearing machine to cut and process the metal plate into a strip-shaped belt groove blank for use;

[0044] Rim blank: Use a shearing machine to cut and process the metal plate into a strip-shaped rim blank for use. It should be ensured that the width of the rim blank is not less than that when the belt groove rings (three lanes) are arranged side by si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com