Automatic tool changing mechanism for induction quenching machine tool inductors

A technology of induction hardening and automatic tool change, which is applied in the direction of quenching device, energy efficiency improvement, heat treatment equipment, etc., can solve the problems that the automatic and fast switching of the sensor library cannot be realized, and achieve the effect of storage and contact precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

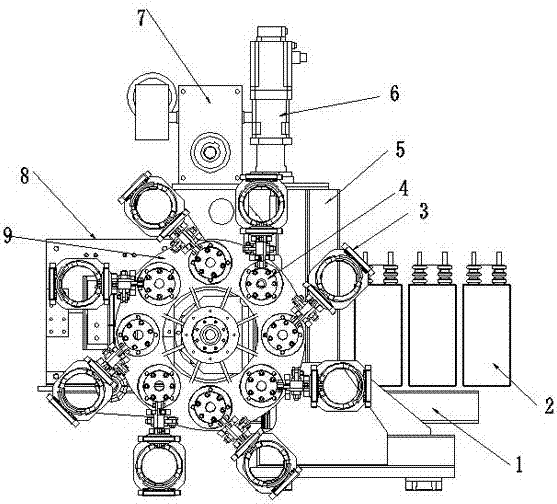

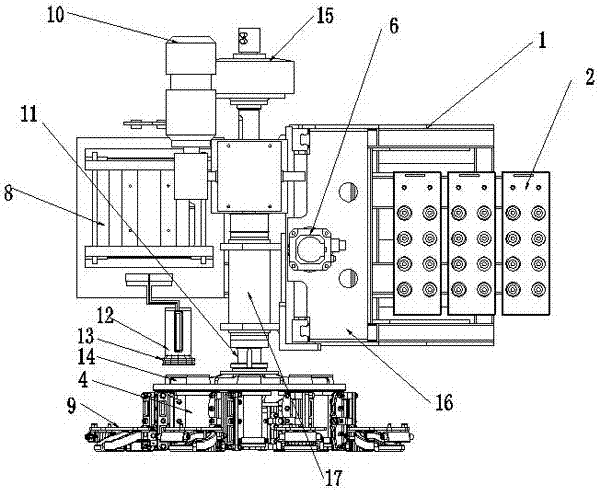

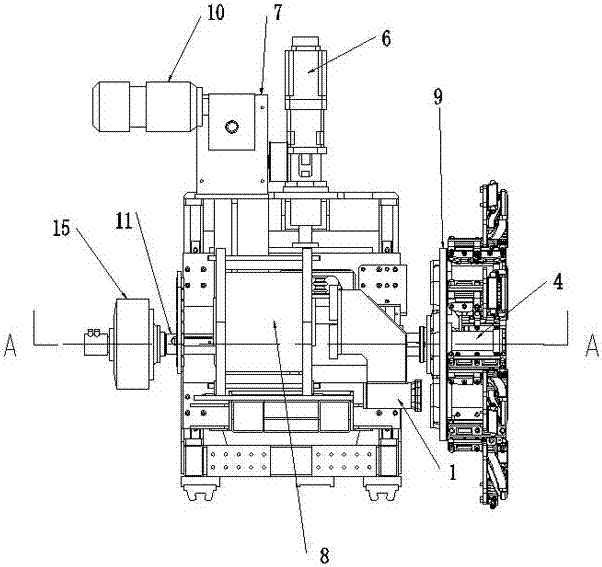

[0022] combine Figure 1-Figure 5 As shown, the present invention is further described as follows: the induction hardening machine tool sensor automatic tool change mechanism includes a bed, and the bed is integrally formed by a base plate 1 and a vertical support plate 16, and the vertical support plate 5 is provided with a vertical guide rail, and on the vertical guide rail Supported by a slide plate 5, the top of the vertical support plate is provided with an adjustment motor 6, and the adjustment motor drives the slide plate 5 through a ball screw drive; on the bottom plate, a compensation capacitor 2, a transformer 8, and a supplementary capacitor are respectively installed on both sides of the vertical support plate Connected in parallel with the transformer, a disc rotation mechanism is fixed on the slide 5, and the transformer is installed on the bottom plate on one side of the slide;

[0023] The disc rotation mechanism includes a fixed seat 17, a main shaft 11, a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com