Overlapped type prefabricated two-cabin assembled pipe gallery structure and construction method thereof

A construction method and pipe gallery technology, which can be applied to basic structure engineering, underwater structures, artificial islands, etc., can solve problems such as high requirements for on-site construction conditions, difficult waterproofing, and many joints in component assembly, so as to improve the connection Strength and integrity, solve unlucky or cleaning difficulties, good cross-working environment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

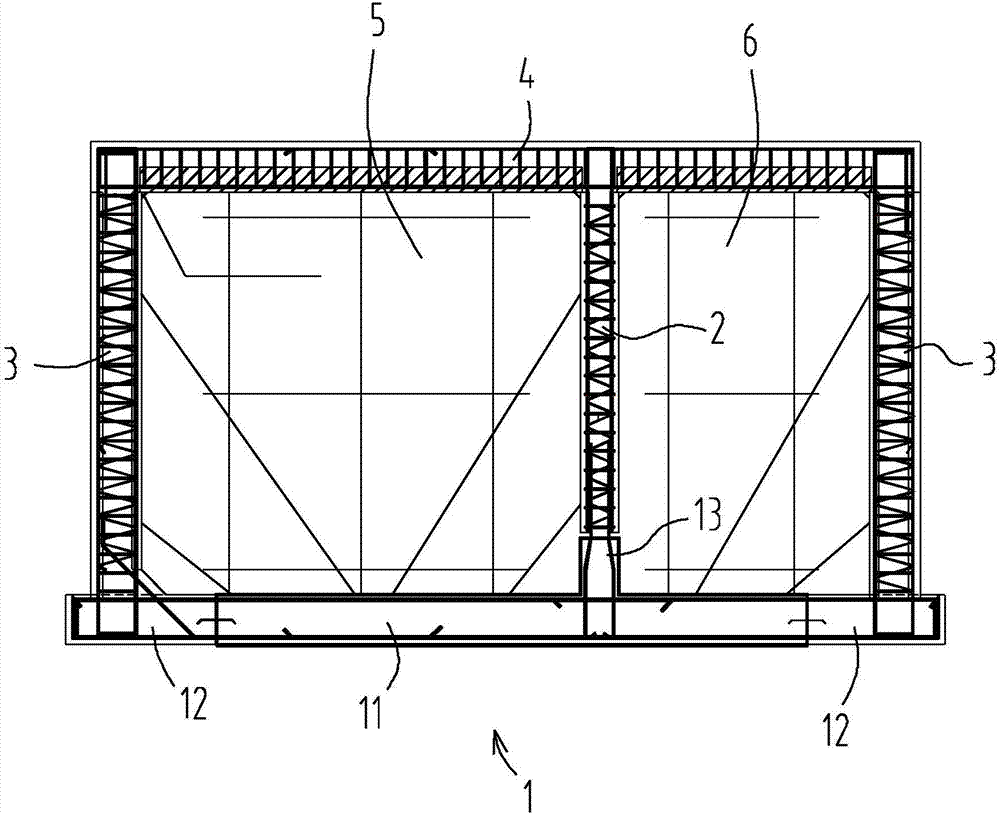

[0028] like figure 1 As shown, the structure of the two-cabin assembled pipe gallery includes the bottom plate 1, the inner wall plate 2, the outer wall plates 3 on both sides and the roof plate 4, all of which are prefabricated panels, and are enclosed into a comprehensive cabin 5 and a natural gas tank 6 arranged on the left and right, where the bottom plate It is divided into a first bottom plate 11 and a second bottom plate 12, wherein the first bottom plate is poured in advance, and a hanging formwork 13 is formed in the middle, and the hanging formwork is connected and poured with the inner wall panel 2. The first bottom plate Steel plate waterstop construction joints are reserved on both sides.

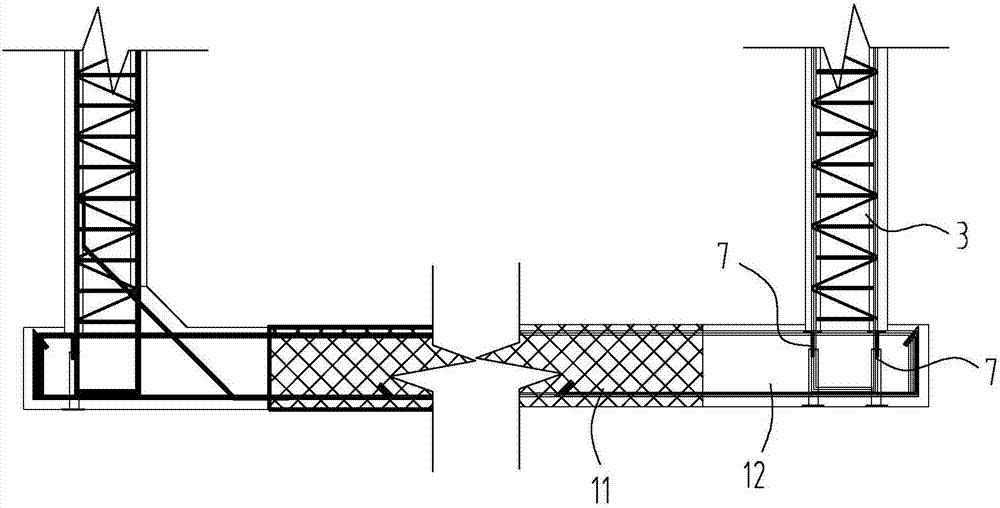

[0029] like figure 2 As shown, the second bottom plate 12 is connected and poured with the outer wall panel 3 through a plurality of props ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com