Control system and method for protecting inside blow-out preventer of oil drilling rig top drive

A control system and internal blowout prevention technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve problems such as damage to the top drive internal blowout preventer, and achieve the effect of avoiding damage and other dangerous situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

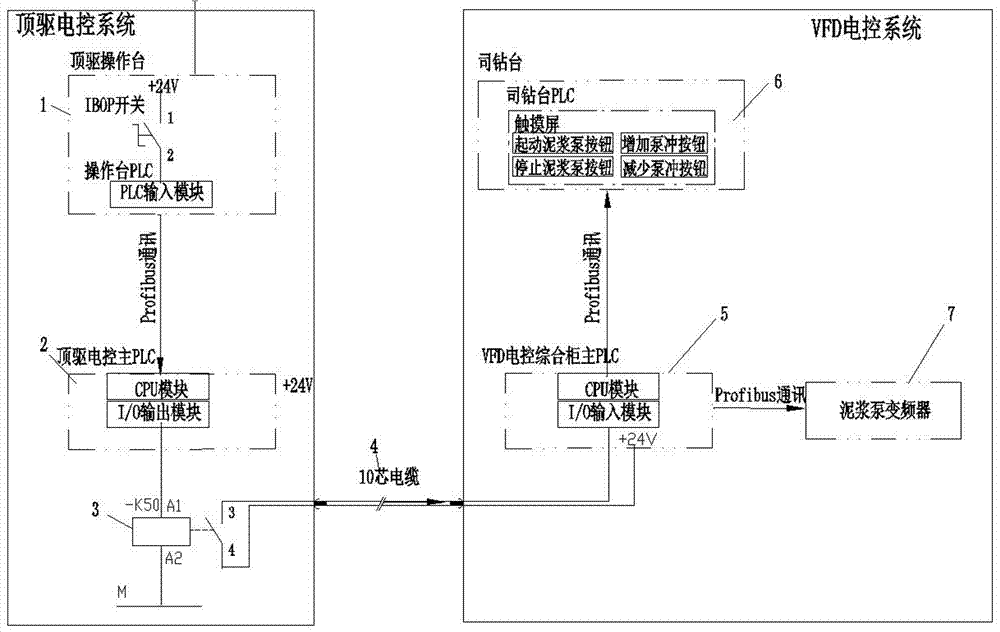

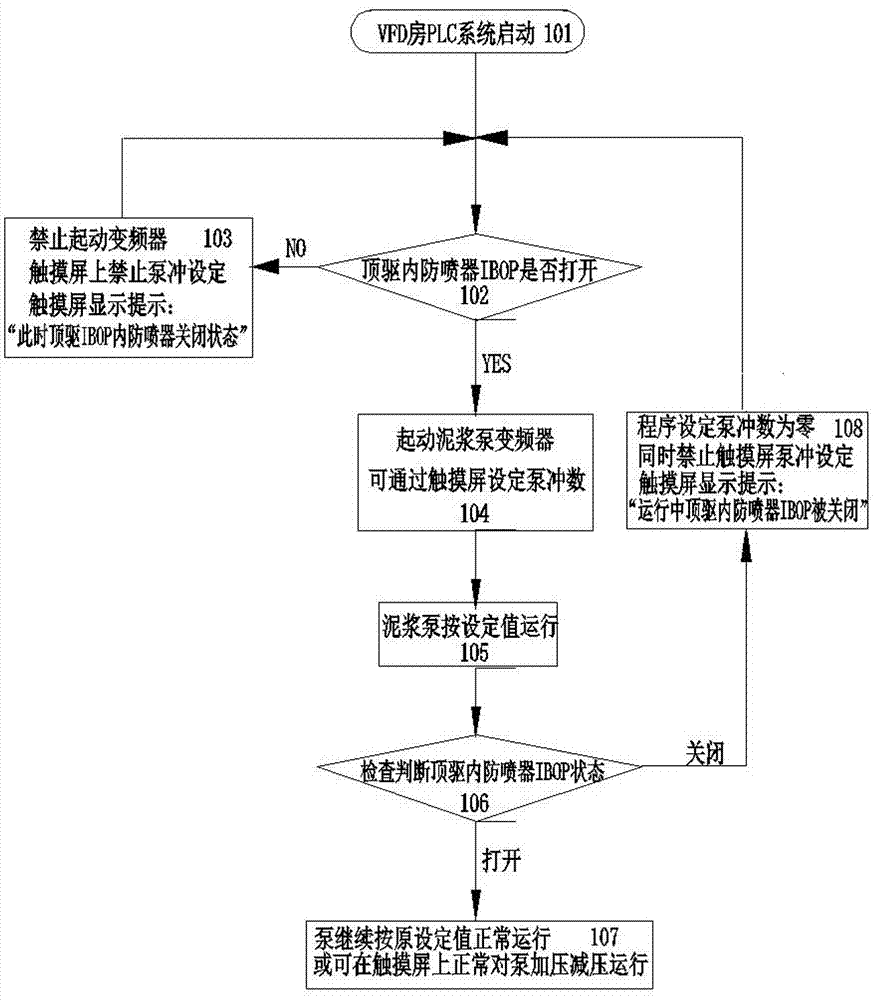

[0017] Such as figure 1 As shown, a control system for protecting the top drive internal blowout preventer of an oil drilling rig includes a top drive electric control system and a VFD electric control system; the top drive electric control system includes a top drive operating console 1 and a top drive electric control main PLC 2 , -K50 relay 3, the top drive console 1 is provided with a top drive IBOP switch and PLC, and the PLC is provided with an input module, and the top drive electric control master PLC 2 includes a CPU module and an I / O output module; the VFD electric control system Including VFD electric control integrated cabinet main PLC 5, driller's floor 6, mud pump inverter 7, VFD electric control integrated cabinet main PLC includes CPU module and I / O input module, driller's floor 6 is equipped with driller's floor PLC and touch screen; Wherein, one end of the IBOP switch of the top drive is connected to the +24V power supply, and the other end is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com